Mixing apparatus for colloidal electrolyte, colloidal electrolyte and preparation method thereof

A colloidal electrolyte and mixing device technology, applied in mixers, chemical instruments and methods, mixers with rotary stirring devices, etc., can solve the problems of low storage capacity and low capacity of batteries, and achieve long discharge time and cycle life. Low, high-capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

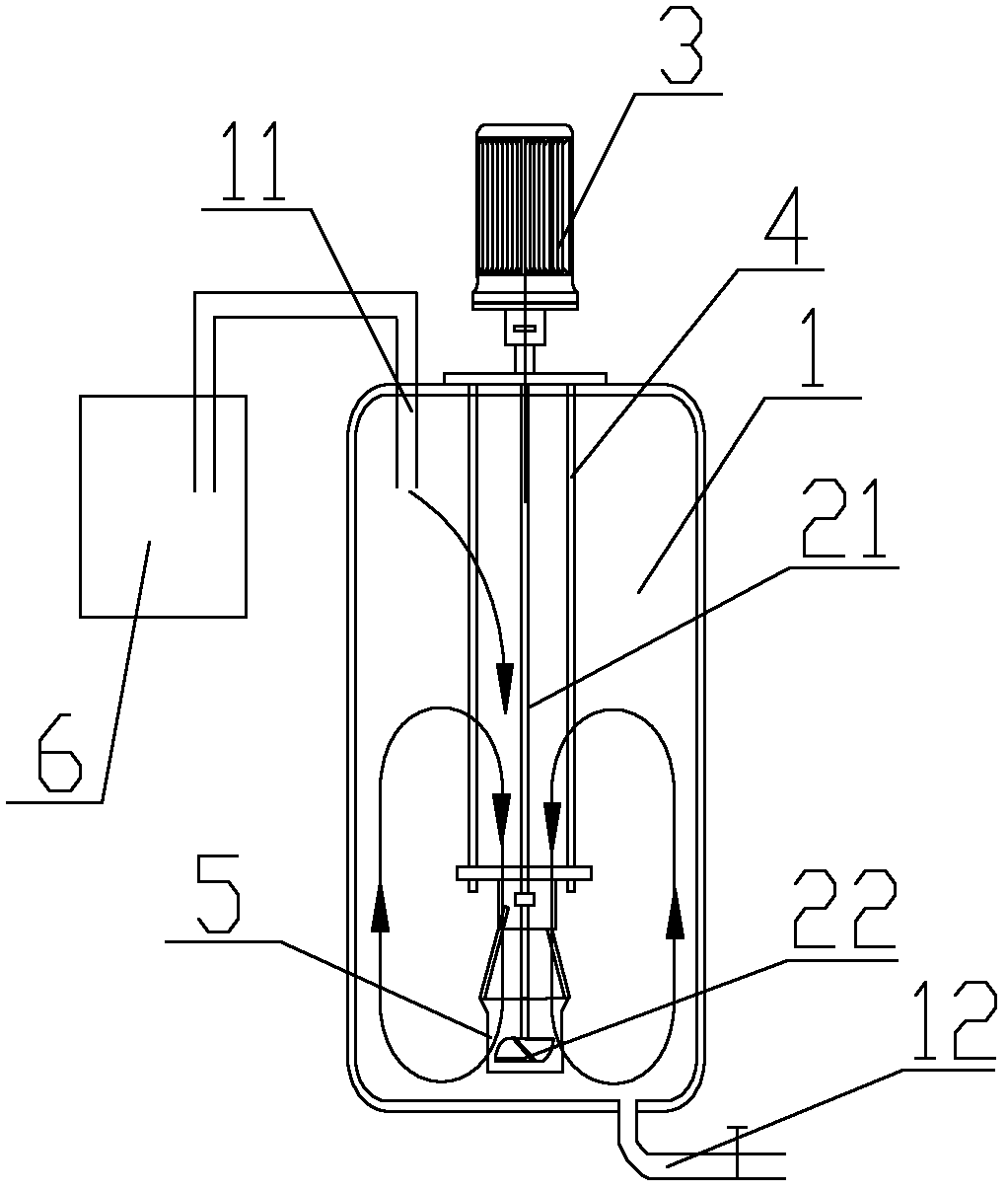

[0072] The present invention also provides a method for preparing the colloidal electrolyte described in the above technical solution, comprising the following steps:

[0073] A) adding sulfuric acid aqueous solution, trisodium citrate and sodium silicate to the tank body of the colloidal electrolyte mixing device described in the above technical scheme;

[0074] B) adding nano silicon dioxide to the raw material storage device of the colloidal electrolyte mixing device described in the above technical scheme;

[0075] c) Turn on the motor of the colloidal electrolyte mixing device described in the above technical solution, and obtain the colloidal electrolyte after stirring.

[0076] First, add sulfuric acid aqueous solution, trisodium citrate and sodium silicate into the tank of the colloidal electrolyte mixing device, add nano-silicon dioxide into the raw material storage device, turn on the motor, and the rotor rotates at a high speed under the action of the motor to gener...

Embodiment 1~3

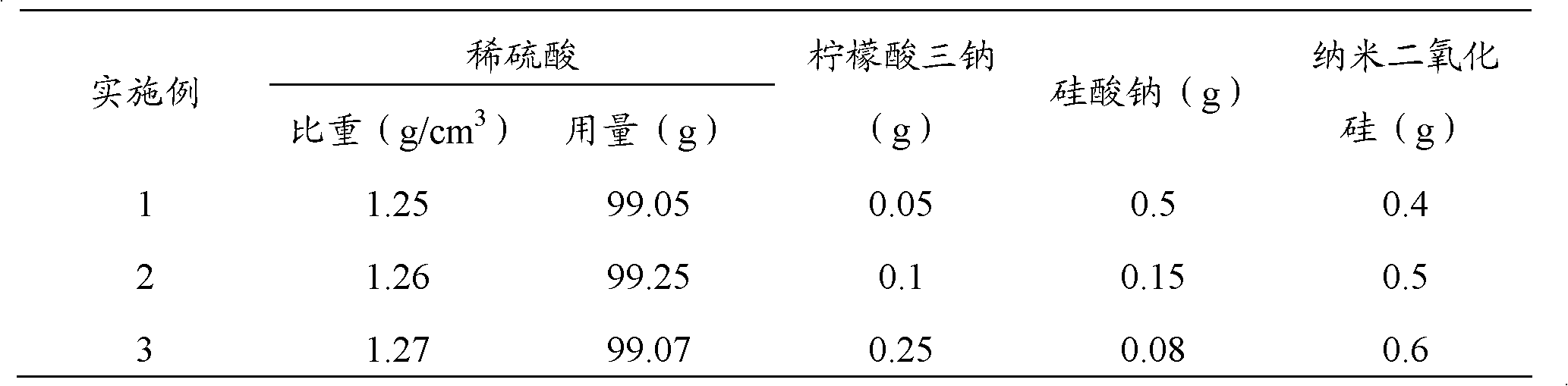

[0086] Inject dilute sulfuric acid figure 1 In the mixing device shown, then add trisodium citrate and sodium silicate into it; add nano-silica into the raw material storage device, turn on the motor, first mix with a speed of 15m / s for 8min, and then mix at a speed of 40m / s Mix at a high speed for 25 minutes to obtain a colloidal electrolyte. The ratio of raw materials used in each embodiment is shown in Table 1.

[0087] Table 1 The ratio of raw materials used in Examples 1 to 3 of the present invention

[0088]

Embodiment 4

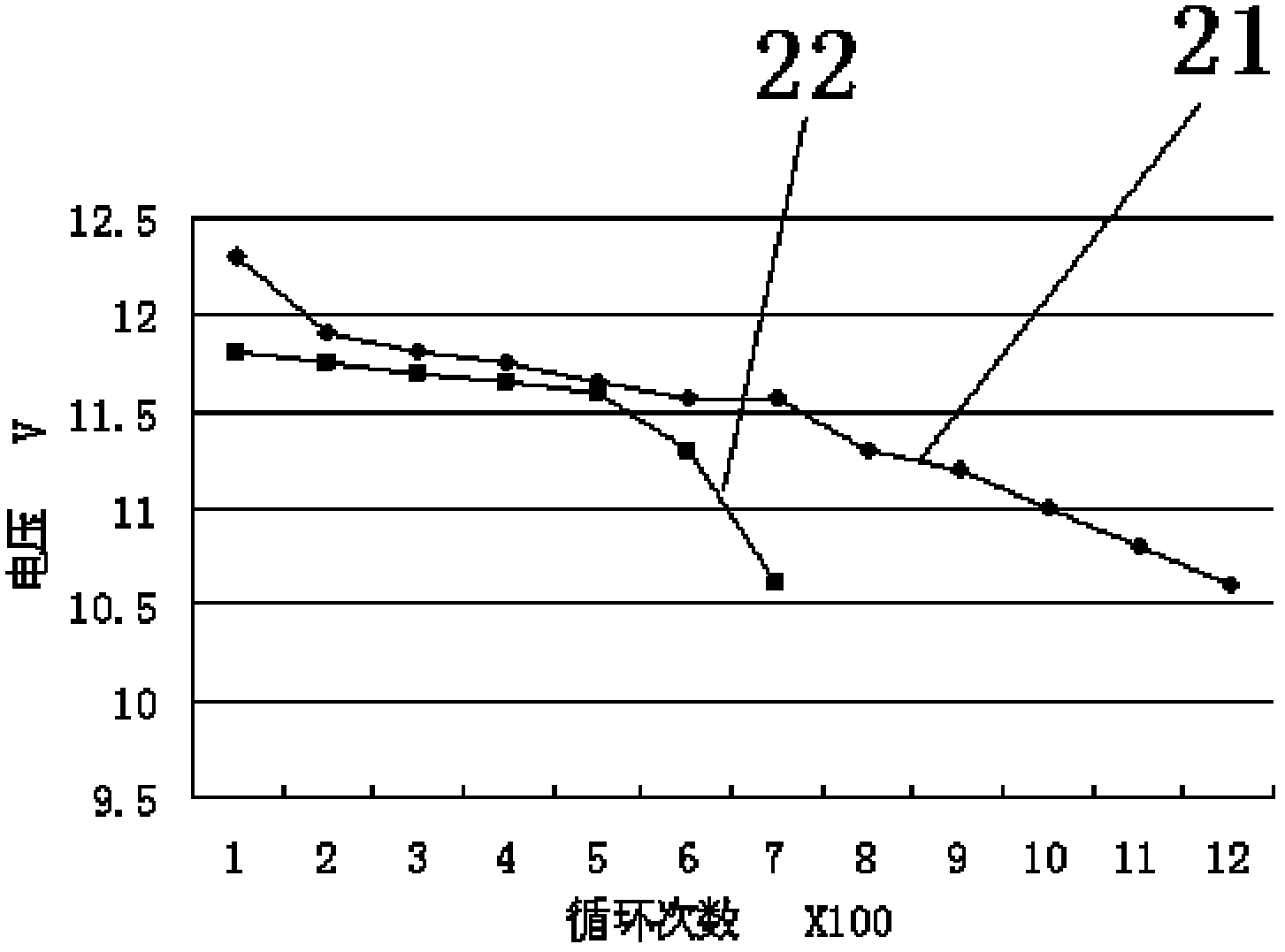

[0096] The colloidal electrolytes prepared in Examples 1-3 and Comparative Examples 1-3 were respectively assembled into batteries of model 6MF9, whose specifications were 12V, 9Ah.

[0097] The capacity test was carried out on the storage battery, and the results are shown in Table 2. Table 2 shows the capacity test results of the 6MF9 storage battery provided by the embodiment of the present invention and the comparative example.

[0098] The capacity test result of the 6MF9 accumulator that table 2 embodiment of the present invention and comparative example provide

[0099] Unit: Ah

[0100]

[0101] It can be seen from Table 2 that the battery assembled with the colloidal electrolyte provided by the present invention has better capacity at different discharge rates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com