Insulated gate bipolar transistor with dielectric layer at collector terminal

A technology of bipolar transistors and dielectric layers, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as device avalanche breakdown, device shutdown failure, device temperature rise, etc., to reduce hole injection, current Concentration suppression, area reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

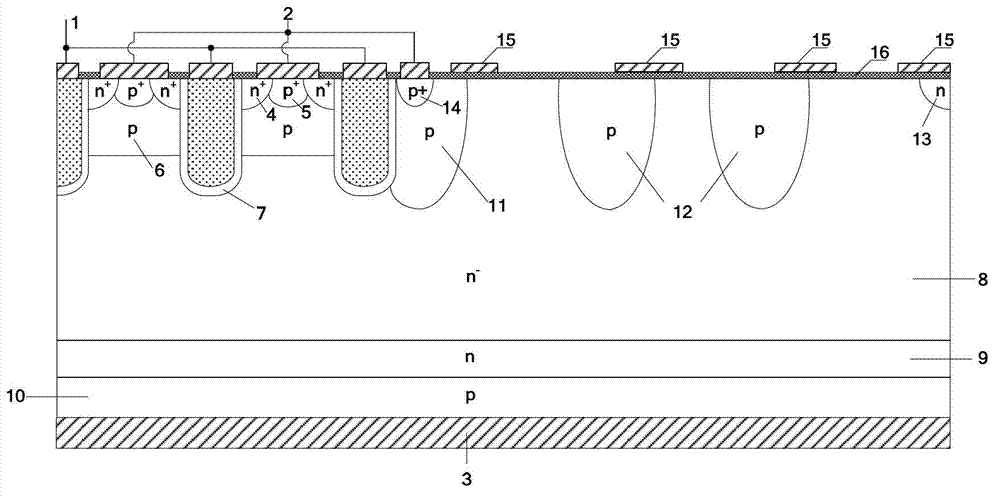

[0024] An insulated gate bipolar transistor with a dielectric layer at the collector terminal, such as Figure 2 to Figure 5 As shown, the collector termination region of the IGBT has a dielectric layer 17; the dielectric layer 17 is specifically located at the termination region of the P-type collector region 10 or the termination region of the metal collector 3.

[0025] In the above scheme:

[0026] The dielectric layer 17 can be a continuous structure or a discontinuous structure.

[0027] The dielectric layer 17 can be silicon oxide, silicon nitride, silicon oxynitride, borophosphosilicate glass and other dielectric materials.

[0028] The length, width, thickness and shape of the dielectric layer 17 can be changed accordingly according to design requirements.

[0029] The gate electrode of the insulated gate bipolar transistor may be a planar gate, a trench gate, or a planar gate or a trench gate with a carrier storage layer.

[0030] The collector of the IGBT may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com