Performance calculating method of finned tube evaporator under frosting working condition

A calculation method and evaporator technology, applied in evaporator/condenser, calculation, instrument, etc., can solve the problems of waste of raw materials, large gap in evaporator performance, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

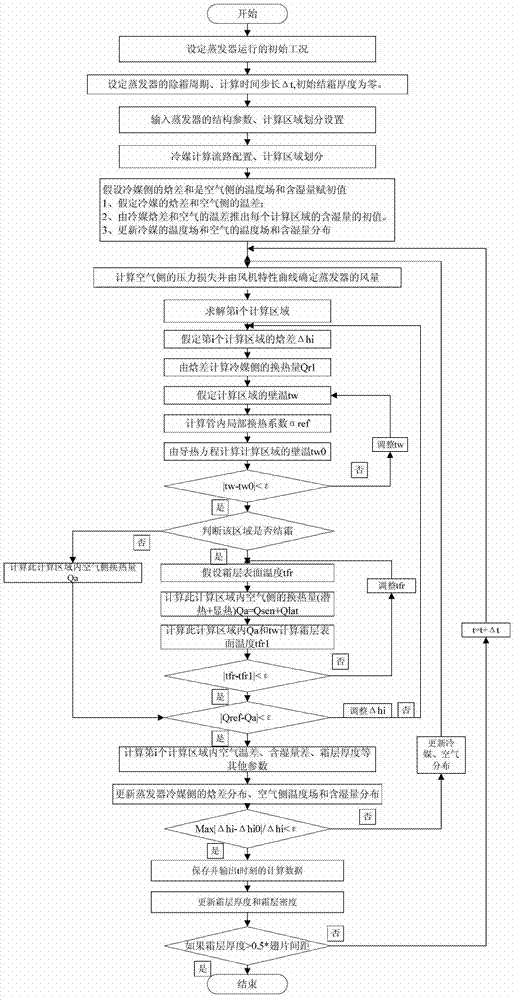

[0090] In order to facilitate those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0091] The program flowchart of the present invention, as figure 1 As shown, the specific steps are as follows:

[0092] A. Determine the operating conditions of the evaporator according to the user's input.

[0093] Input the initial parameters of the evaporator operation, evaporating temperature, inlet state of the refrigerant (pressure and enthalpy), inlet state of the humid air (temperature and relative humidity), and call the refrigerant physical property calculation class and the wet air physical property calculation class to determine the refrigerant inlet. parameter.

[0094] For example: the selected refrigerant is R22, the known pressure is 465kPa, the enthalpy is 220kJ / kg, A.Pk=465; A.H=220; LoaderMgr::getInstance(R22).getLoader()->getPHFL1(A,B); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com