Online dilution system and dilution method for sugar boiling material

A material and sugar cooking technology, which is applied in the field of molasses dilution technology, can solve the problems of increased material viscosity, decreased material purity, poor absorption, etc., and achieve the effects of accelerating crystallization speed, reducing the probability of sticking crystals, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

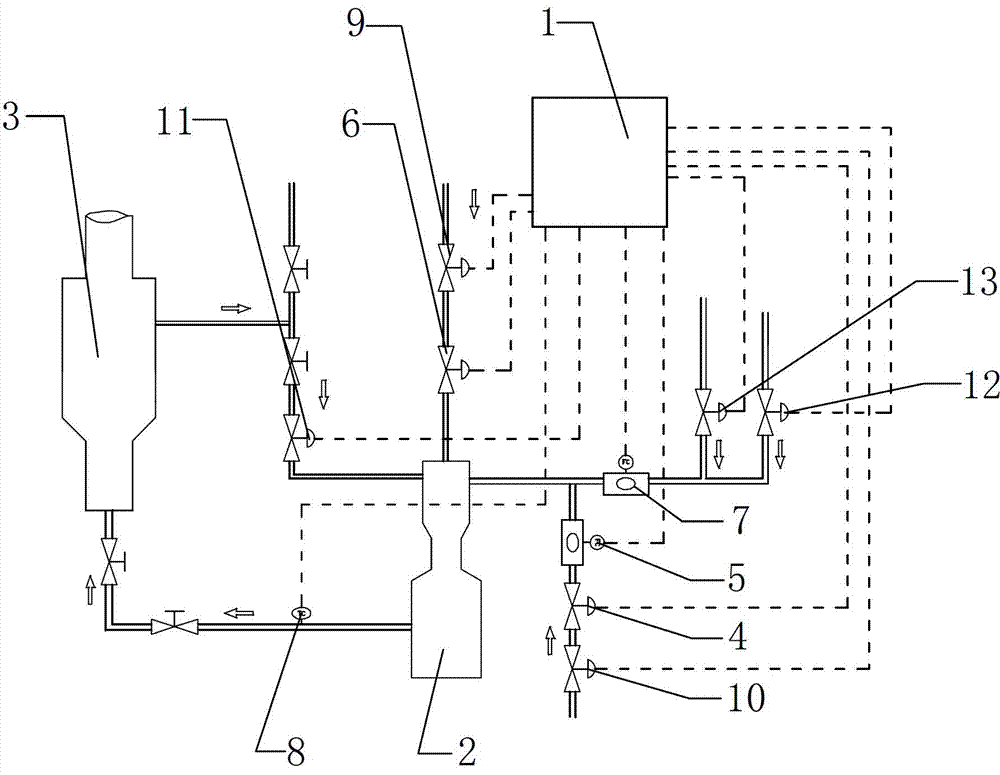

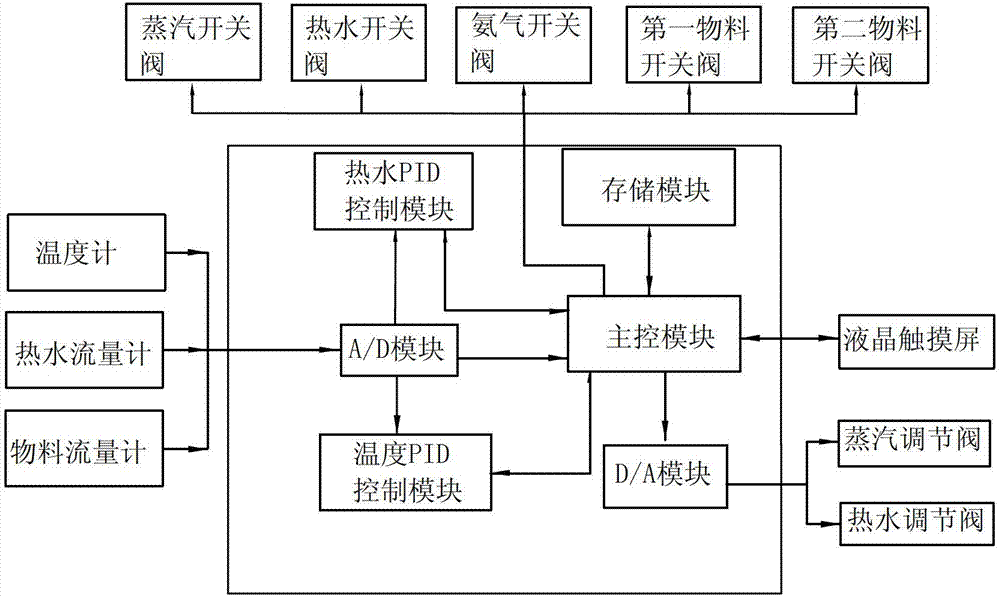

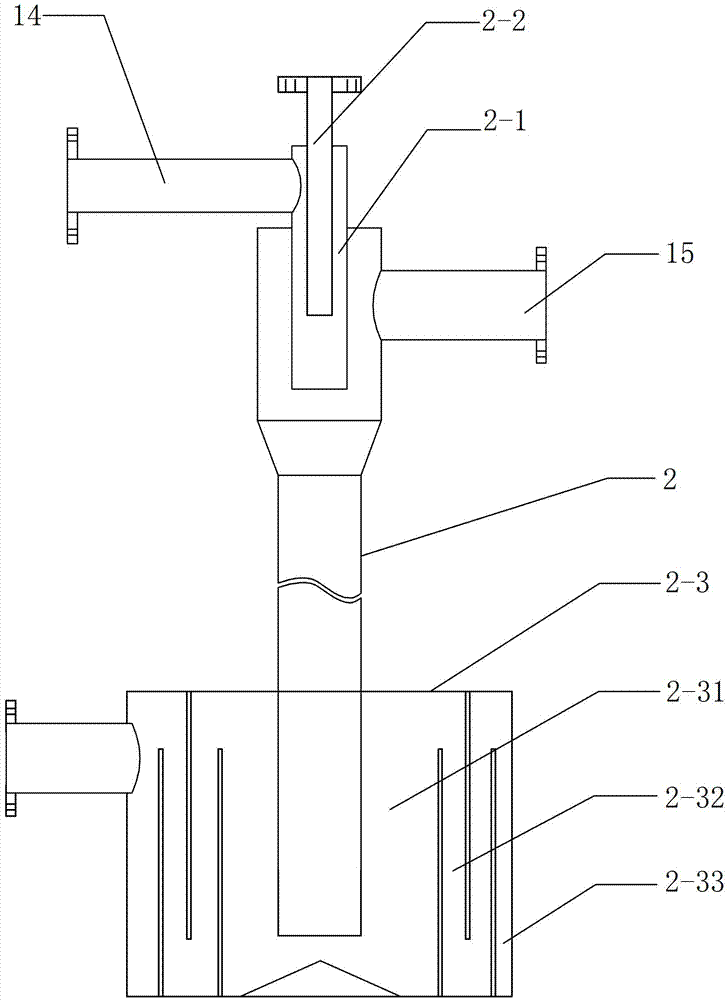

[0035] The present invention is a continuous feeding regulating system for sugar cooking process, such as figure 1 It includes a controller 1, a mixing pipe 15 and a mixing tank 2. The water supply pipe is connected to the inlet of the mixing pipe 15 after passing through the hot water switch valve 10, the hot water regulating valve 4, and the hot water flow meter 5. The pipeline passes through the first material valve and the second inlet valve, and then passes through the material flow meter 7 and is connected to the inlet end of the mixing pipe 15. The outlet end of the mixing pipe 15 is connected with the inlet of the mixing tank 2; the steam pipe passes through the steam The on-off valve 9 and the steam regulating valve 6 are also connected to the inlet of the mixing tank 2; the outlet of the mixing tank 2 is connected to the external sugar cooking tank 3 through a thermometer 8; the input end of the controller 1 is connected to the hot water flow meter 5 and the material fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com