A flip-type electronic chip detection fixture

An electronic chip and detection jig technology, applied in the direction of electronic circuit testing, etc., can solve the problems of inability to contact the detection probe, inaccurate detection results, and easy dislocation, etc., to achieve accurate and reliable detection results, long service life, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

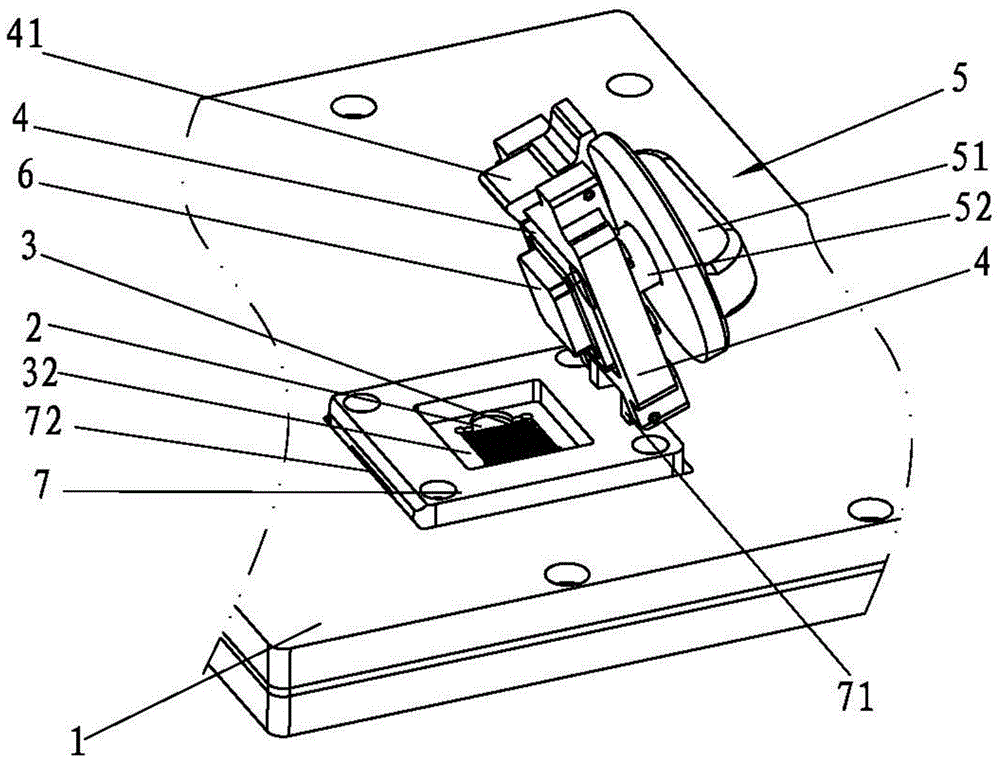

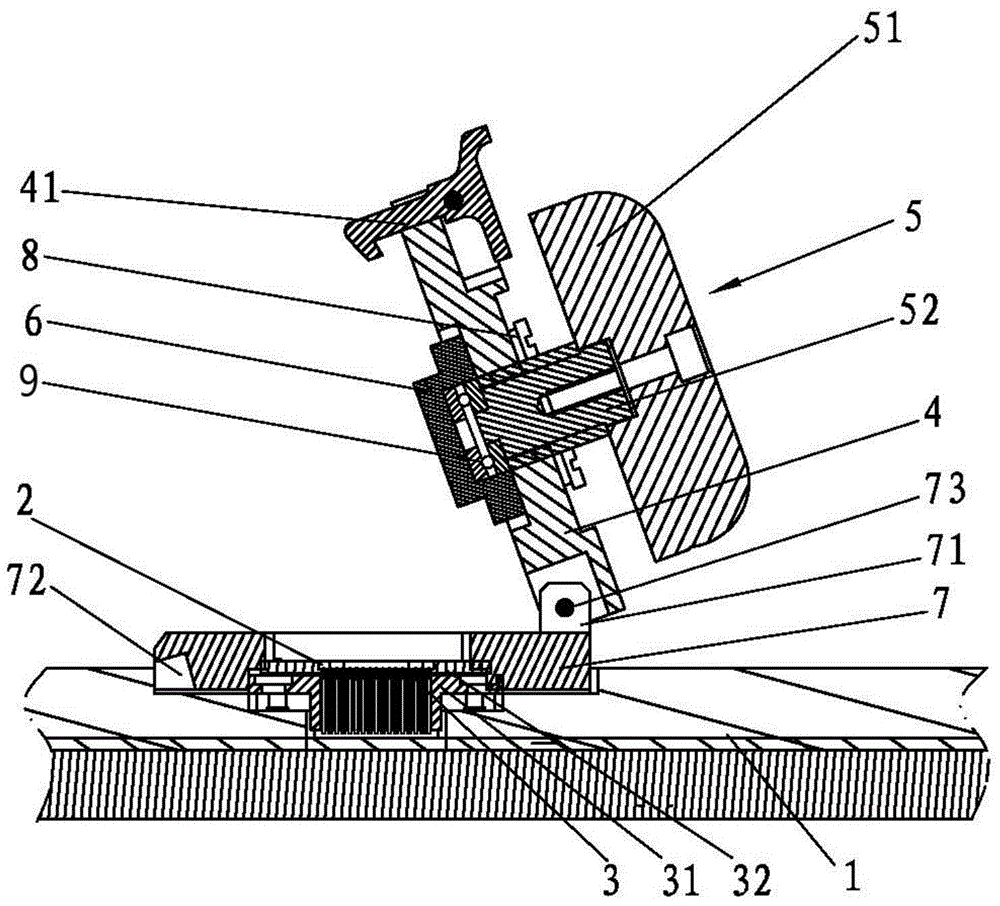

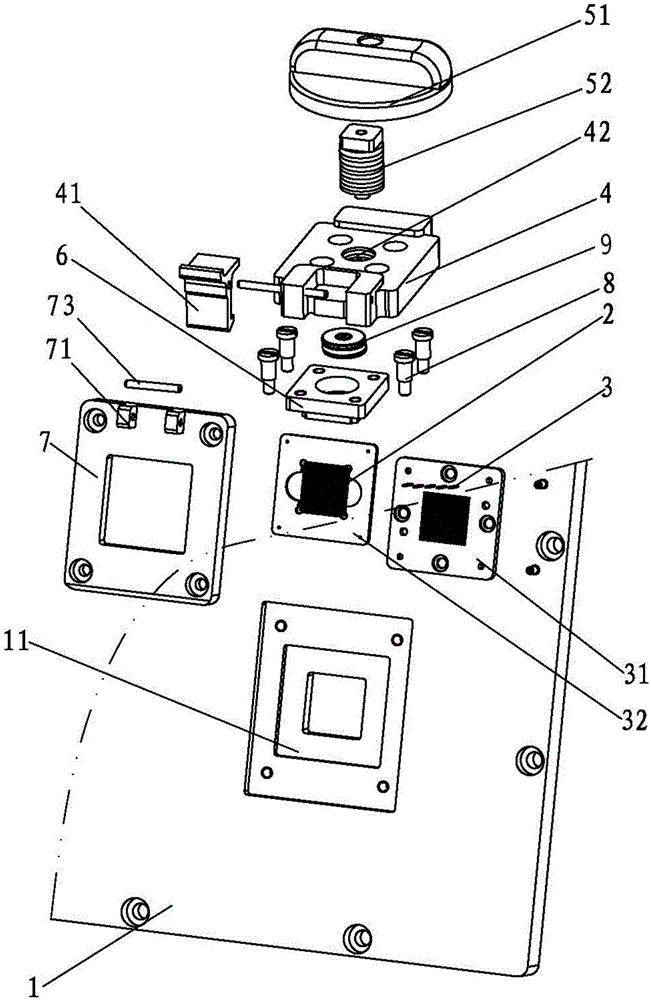

[0016] Attached below Figure 1-3 The present invention is further elaborated:

[0017] A flip-type electronic chip detection jig, comprising a jig bottom plate 1 provided with a detection circuit, a chip accommodating cavity 2 for detecting electronic chips is set on the jig bottom plate 1, and a detection circuit is arranged in the chip accommodating cavity 2 and connected to the chip accommodating cavity 2. The detection probe 3 is matched with the electronic chip, and the cover pressing plate 4 is arranged above the accommodating cavity 2. One side of the cover pressing plate 4 is hinged and arranged on the jig bottom plate 1. The bottom plate 1 is fastened with the pull button 41, and the flip pressing plate 4 is provided with a spinning device 5, and the bottom end of the spinning device 5 is connected with a chip pressing block 6 pressed against the electronic chip.

[0018] In order to better fix the flip cover pressing plate 4, a "back"-shaped fixed mounting seat 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com