Method and device for profile forming of packaging substrate

A packaging substrate and shape technology, which is applied in the field of packaging substrate shape forming methods and devices, can solve problems such as weak force, deviation of a single packaging substrate, and the size of a single packaging substrate cannot meet the requirements, and achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

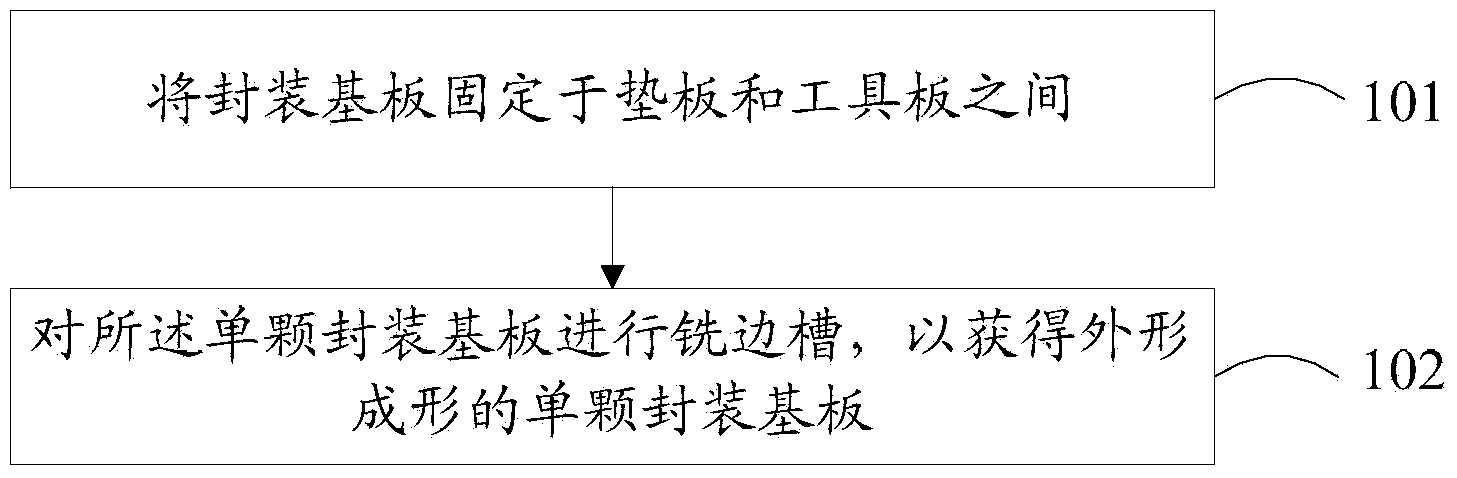

[0027] Such as figure 1 As shown, a packaging substrate shape forming method, including:

[0028] 101. Fix the packaging substrate between the backing board and the tool board, the packaging substrate is composed of several single packaging substrates connected.

[0029] Specifically, such as figure 2 As shown, positioning holes can be set at the four corners of the backing plate 201, the package substrate 202, and the tool plate 203, and these three boards are stacked on the milling table from bottom to top, and fixed with pins 204, that is, the package substrate passes through the positioning The pin is fixed between the backing plate and the tool plate.

[0030] Preferably, the tool plate 203 is a hard tool plate used for milling. The hard tool board is conducive to pressing the package substrate when milling the edge groove, and can make the force of the milling cutter retract on the tool board.

[0031] Of course, the size of the tool plate 203 is the same as that of...

Embodiment 2

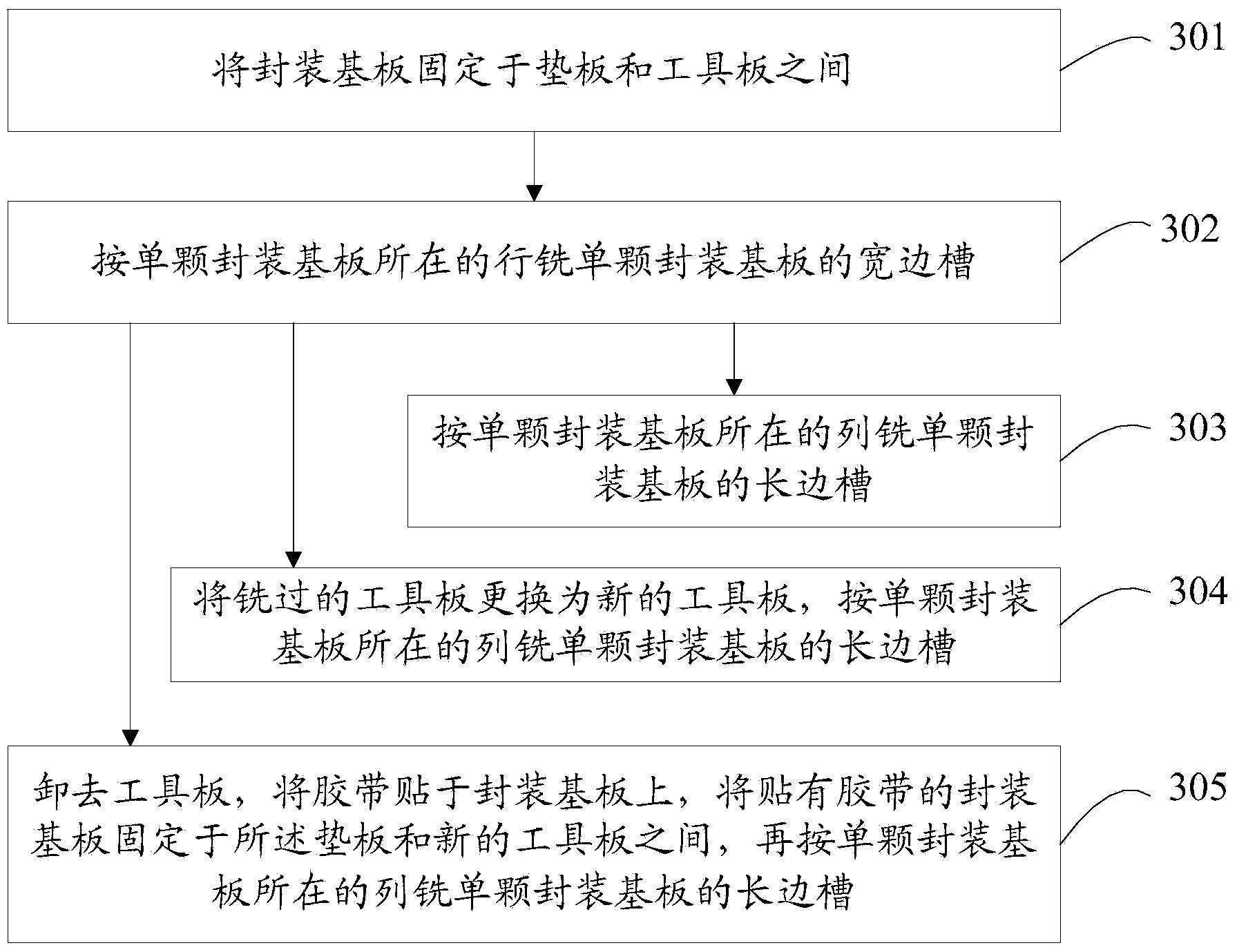

[0035] Such as image 3 As shown, a packaging substrate shape forming method, including:

[0036] 301. Fix the packaging substrate between the backing board and the tool board, the packaging substrate is composed of several single packaging substrates connected.

[0037] Specifically, the package substrate can be fixed between the backing plate and the tool plate through positioning pins, the tool plate is a hard tool plate used for milling, and the size of the tool plate is the same as that of the package substrate.

[0038] This is the same as step 101 in Embodiment 1, and will not be repeated here.

[0039] 302. Mill the wide side groove of the single package substrate according to the line where the single package substrate is located.

[0040] Specifically, after the package substrate is fixed between the backing plate and the tool plate, the milling wide-side slot program in the machine is called, and the wide-side slot is milled according to the line where the single ...

Embodiment 3

[0052] The present invention also provides a corresponding packaging substrate shape forming device, which includes: a backing plate, a tool plate and a milling cutter. An encapsulation substrate is fixed between the backing plate and the tool plate, and the encapsulation substrate is composed of several single encapsulation substrates connected together. The milling cutter is arranged above the tool board, and is used for milling grooves on the packaging substrate fixed between the backing board and the tool board, so as to obtain a shape-shaped single packaging substrate.

[0053] Since the package substrate is fixed between the backing plate and the tool plate, when milling the wide and long sides of a single package substrate, the force of the milling cutter will not cause the deviation of the single package substrate, so that a satisfactory shape can be obtained. A single package substrate with size requirements. The milling cutter here can be installed on the milling ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com