Chinese yam liquor and brewing method thereof

A technology of yam and liquor, which is applied in the field of yam liquor and its brewing, and can solve the problems of strong irritation and spicy taste of liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

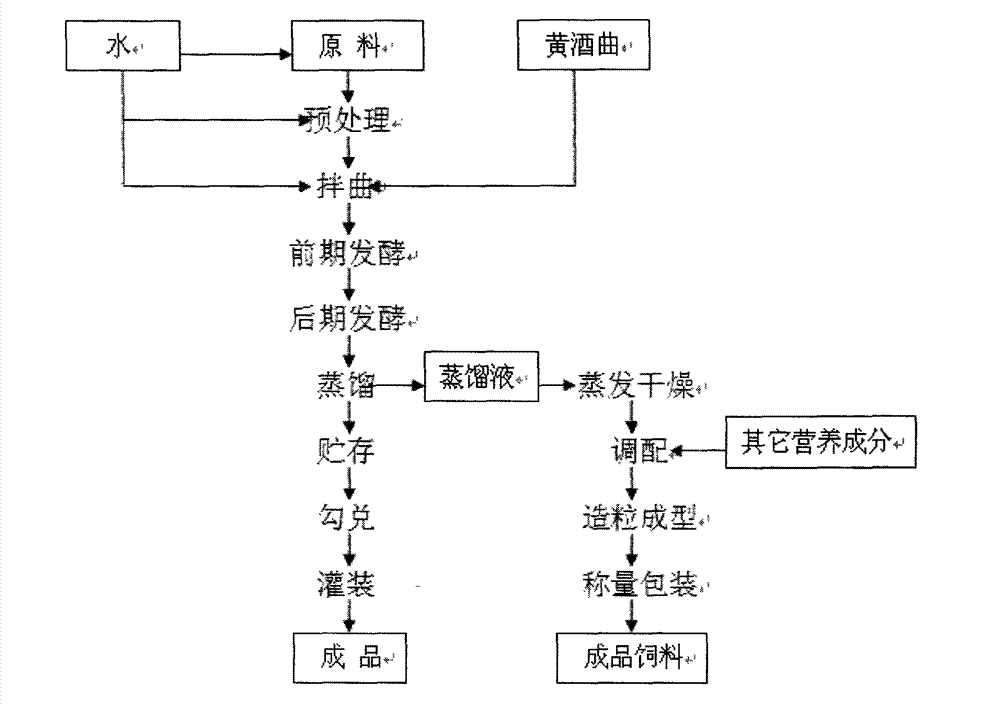

Method used

Image

Examples

Embodiment 1

[0032] (1) Impurity removal of raw materials: Sieve and winnow the dried Chinese yam slices, rice, glutinous rice, millet, and peas to remove impurities contained in the above raw materials.

[0033] (2) Raw material processing: Weigh 33 parts of Chinese yam tablets, wash them, soak them in warm water until they are soft but not rotten, and then crush them; weigh 32 parts of rice, 27 parts of glutinous rice, and 7 parts of millet, and mix them. Wash with pure water, just wash twice; the white turbid liquid can make the wine clear. Weigh 1 portion of peas, wash them, add pure water, put them in a high-pressure cooking pot, and cook them thoroughly.

[0034] (3) Activation of distiller's koji: take yellow rice wine koji with 2.0% of the total amount of raw materials, and activate the distiller's koji with purified water at 28-30°C.

[0035] (4) Vat fall: Put the processed raw materials into a sterilized container, and add activated koji and 2 to 3 times the pure brewing water i...

Embodiment 2

[0041] (1) Impurity removal of raw materials: Sieve and winnow the used yam tablets, rice, glutinous rice, millet and peas to remove impurities contained in the above raw materials.

[0042](2) Cleaning of raw materials: Weigh 35 parts of Chinese yam tablets, wash them, soak them in warm water until they are soft but not rotten, and then crush them; weigh 30 parts of rice, 25 parts of glutinous rice, and 8 parts of millet, and mix them. Wash with pure water, just wash twice; the white turbid liquid can make the wine clear. Weigh 2 portions of peas, clean them, add pure water, put them in a high-pressure cooking pot, and cook them thoroughly.

[0043] (3) Activation of distiller's yeast: take yellow rice wine koji with 2.5% of the total amount of raw materials, and activate the distiller's yeast with pure water at 28-30°C.

[0044] (4) Falling into the vat: put the processed raw materials into a sterilized container, and add activated distiller's yeast and 2 to 3 times pure wa...

Embodiment 3

[0050] (1) Impurity removal of raw materials: Sieve and winnow the used yam tablets, rice, glutinous rice, millet and peas to remove impurities contained in the above raw materials.

[0051] (2) Cleaning of raw materials: Weigh 37 parts of Chinese yam tablets, wash them, soak them in warm water until they are soft but not rotten, and then crush them; weigh 28 parts of rice, 23 parts of glutinous rice, and 9 parts of millet, and mix them. Wash with pure water, just wash twice; the white turbid liquid can make the wine clear. Weigh 3 portions of peas, clean them, add pure water, put them in a high-pressure cooking pot, and cook them thoroughly.

[0052] (3) Distiller's koji activation: Weigh yellow rice wine koji with 3.0% of the total amount of raw materials, and activate the distiller's koji with purified water at 28-30°C.

[0053] (4) Falling into the vat: put the processed raw materials into a sterilized container, and add activated distiller's yeast and 2 to 3 times pure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com