Technology for preparing diethyl phosphite by by-product of triethyl phosphite

A technology of diethyl phosphite and triethyl phosphite, which is applied in the field of diethyl phosphite preparation, can solve the problems of low synthesis reaction temperature, a large number of anti-corrosion equipment, and large environmental pollution, and achieve low equipment investment and market The effect of low value cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

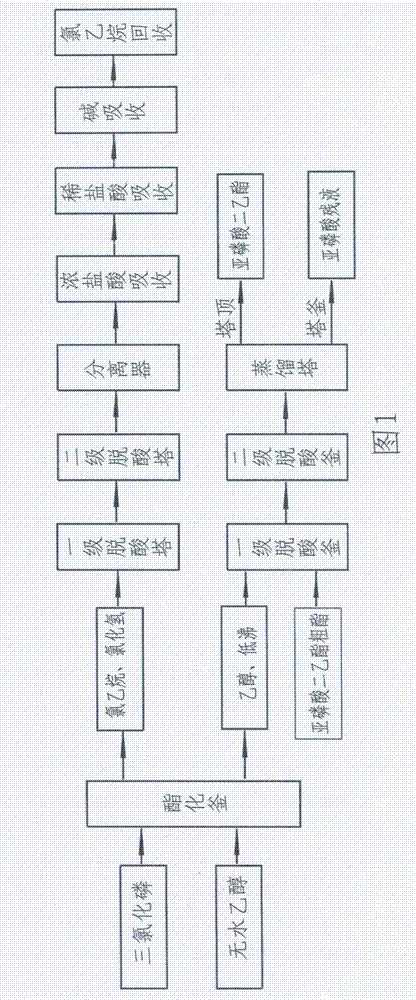

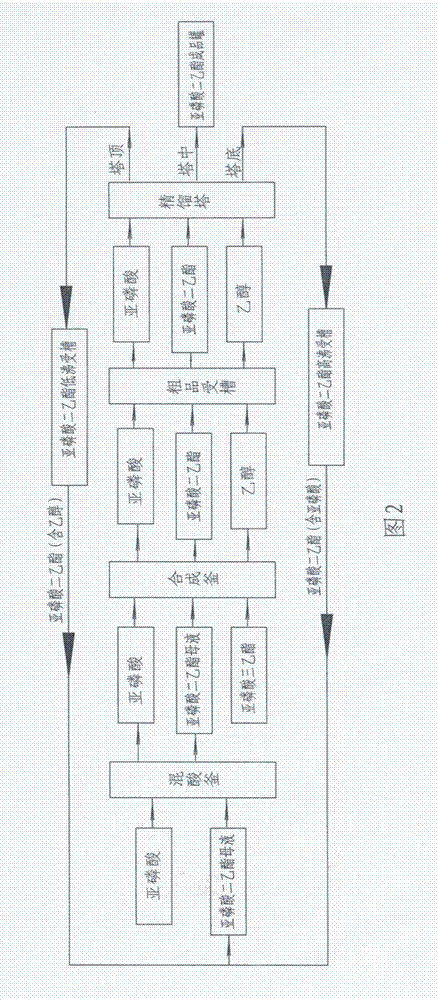

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below by a specific embodiment, take the diethyl phosphite product of producing 1000Kg as example.

[0043] The triethyl phosphite charging amount in the present embodiment is 818.3 kg, the phosphorous acid input amount is 196.1 kg, the product diethyl phosphite produced is 1000 kg, and the total yield of triethyl phosphite is 98%, which The content is 99.0%.

[0044] Step 1: Prepare Mixed Acid

[0045] The acid mixing kettle is an enamel kettle, and the stirring speed is 130r / min. Take 196.1kg of diethyl phosphite mother liquor (diethyl phosphite mother liquor comes from the distillate distillate diethyl phosphite distillation tower and the raffinate at the bottom of the tower, the components are 10% ethanol, diethyl phosphite 87%, phosphorous acid 3%) into the mixed acid kettle, raise the temperature of the mixed acid kettle to 75°C, start stirring and dissolving, then put 196.1kg of phosphorous acid into the mixed aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com