Molybdenum-rich special controlled-release fertilizer for leguminous crops, and preparation method and application thereof

A controlled-release fertilizer and leguminous technology, applied in the direction of application, fertilizer mixture, fertilization device, etc., can solve the problems of increased labor, short seed dressing fertilizer effect time, etc., to avoid direct contact, good effectiveness, and reduce fertilization costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

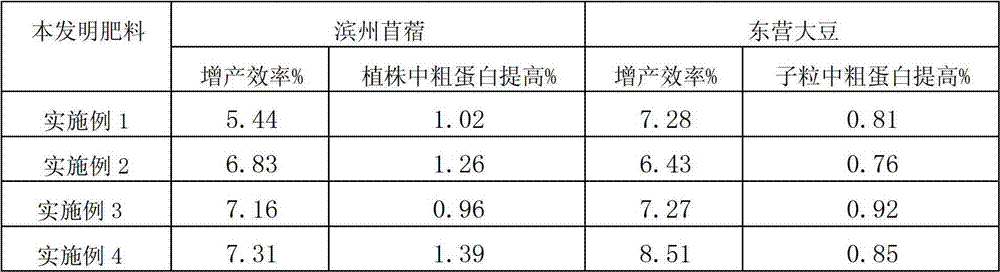

Examples

Embodiment 1

[0046] The molybdenum-rich controlled-release fertilizer for leguminous crops consists of raw materials: 150 kg of molybdenum-containing weathered coal-coated urea, 150 kg of polymer-coated urea, 400 kg of diammonium phosphate, and 300 kg of granular potassium chloride.

[0047]The molybdenum-containing weathered coal-coated urea is obtained by coating granular urea as the core fertilizer according to the prior art, and the coating material is a combination of weathered coal:ammonium molybdate=1:0.10 mass ratio, and the coating material accounts for 1% of the granular urea. The mass ratio of is 5.4wt%;

[0048] The polymer material coated urea is obtained by coating granular urea as the core fertilizer according to the prior art, and the coating material is a combination of recycled polyethylene film resin and recycled polystyrene foam resin in a mass ratio of 1:1 and accounts for The total amount of recycled polyethylene film resin and recycled polystyrene foam resin is compo...

Embodiment 2

[0057] The raw material composition of molybdenum-rich controlled-release fertilizer for leguminous crops is: 100 kg of molybdenum-containing weathered coal-coated urea, 200 kg of polymer-coated urea, 300 kg of diammonium phosphate, and 400 kg of granular potassium chloride.

[0058] Preparation method, the steps are as follows:

[0059] (1) Take 15 kg of weathered coal, add 2.1 kg of ammonium molybdate, and mix evenly to obtain molybdenum-containing weathered coal. Take 3 kg of bisphenol A and 0.36 kg of triethylenetetramine, and mix them uniformly to obtain a binder. Take granular urea with a particle size of 2 to 3 mm, preheat it to 70°C in a drum, and spray the prepared binder onto the rotating urea particles. The mass ratio of the binder to the granular urea is 0.4 wt%, and then spray a layer of molybdenum-containing weathered coal, the mass ratio of molybdenum-containing weathered coal to urea is 2.1wt%, after solidification, repeat the above process twice to obtain mol...

Embodiment 3

[0064] The molybdenum-rich controlled-release fertilizer for leguminous crops consists of raw materials: 200 kg of molybdenum-containing weathered coal-coated urea, 100 kg of polymer-coated urea, 350 kg of diammonium phosphate, and 350 kg of granular potassium chloride.

[0065] Preparation method, the steps are as follows:

[0066] (1) Take 15 kg of weathered coal, add 1.9 kg of ammonium molybdate, and mix evenly to obtain molybdenum-containing weathered coal. Get 3 kilograms of bisphenol A, 0.42 kilograms of triethylenetetramine, mix evenly, get binder; Get the granular urea of particle diameter 2 ~ 3 millimeters, preheat to 65 ℃ in the rotating drum, put the prepared binder Spray onto the rotating urea granules, the mass ratio of the amount of binder to the granular urea is 0.5wt%, and then spray a layer of prepared molybdenum-containing weathered coal, the mass ratio of the amount of molybdenum-containing weathered coal to urea is 2.5% wt%, after curing, repeat the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com