Metal plate bending and punching integrated hydraulic machine

A metal plate and one-piece technology, applied in the field of hydraulic presses, can solve problems such as slowing down the work process, increasing labor operations for the operator, and single structure, and achieve the effect of speeding up the work process and reducing labor operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

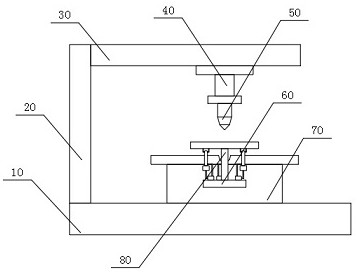

[0077] see Figure 1-6 , metal plate bending and punching integrated hydraulic press, including installation rod 30, hydraulic cylinder 40, bending plate 50, bending table 70, base 10, and support rod 20;

[0078] The base 10 is used for the positioning support of the bending table 70 and the strut 20;

[0079] The strut 20 is fixedly connected to the upper end of the base 10, and is used for the installation support of the installation rod 30;

[0080] The installation rod 30 is fixedly connected to the upper right end of the support rod 20, and is used for the installation and support of the hydraulic cylinder 40;

[0081] The hydraulic cylinder 40 is fixedly connected to the bottom end of the installation rod 30, and is used to provide power for the bending plate 50 to work;

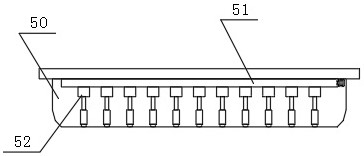

[0082] The bending plate 50 is fixedly connected to the bottom end of the hydraulic cylinder 40, and is used for bending the metal plate;

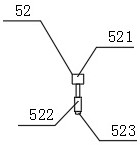

[0083] Wherein, the bending plate 50 is provided with a t...

Embodiment 2

[0110] see Figure 7-8 , because there will be a certain vibration during the punching process, the bent metal plate will shake left and right when it is punched, which will lead to deviations in the punched holes on the metal plate. Therefore, a fixing mechanism 60 is designed to bend the bent The latter metal plate is fixed.

[0111] The fixing mechanism 60 is fixedly connected to the front end surface of the bending table 70, and is used for fixing the bent metal plate;

[0112] Wherein, the fixing mechanism 60 includes a supporting plate 61, a fixing platform 62, a supporting rod 80, and a fixing assembly 63;

[0113] The fixed table 62 is fixedly connected to the front end surface of the bending table 70, and is used for the installation and support of the air pump 634;

[0114] The support rod 80 is fixedly connected to the upper end of the fixed table 62, and is used for positioning and supporting the support plate 61;

[0115] The support plate 61 is fixedly connect...

Embodiment 3

[0138] see Figure 9-11 , due to the different materials of the metal plates, sliding will occur when the push block 334 fixes the metal plate, and the situation of fixing is unstable. For this reason, a suction cup 338 is designed to ensure the stability of the connection between the push block 334 and the metal plate.

[0139] The suction cup 338 is fixedly connected to the bottom surface of the push block one 334, firstly adsorbed on the top surface of the metal plate by the suction cup 338, and then driven by the pneumatic rod one 333 to move the push block one 334, so that the push block one 334 is closely connected to the top surface of the metal plate To ensure the stability of the connection between the push block one 334 and the metal plate.

[0140] Since there will be impurities on the metal plate, in order to ensure that the suction cup 338 can be tightly adsorbed on the end surface of the metal plate, a fastening device 339 is designed to remove impurities on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com