Wear-resistant pouring material used for tertiary air pipe elbow of cement kiln

A pipe elbow and cement kiln technology, which is applied in the field of castables, can solve the problems of high water absorption, inability to meet the long-term use of tertiary air pipe elbows, poor erosion resistance, erosion resistance and thermal shock stability, etc., to achieve water absorption Low efficiency, good overall compactness, corrosion resistance and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

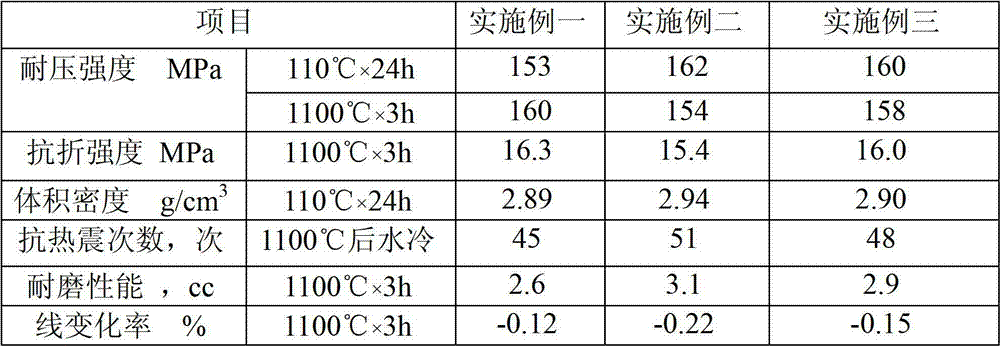

Embodiment 1

[0027] A wear-resistant castable for a cement kiln tertiary air duct elbow, the components of which are composed of:

[0028] Brown corundum with a particle size of 3-5mm 29%;

[0029] Brown corundum with a particle size of 1-3mm 12%;

[0030] Brown corundum with a particle size of 0.088-1mm 10%;

[0031] Andalusite with a particle size of 0.088-1mm 8%;

[0032] SiC 12% with a particle size of 1-3 mm;

[0033] SiC fine powder 4%;

[0034] Andalusite powder 2%;

[0035] White corundum powder 5%;

[0036] α-Al 2 o 3 Micropowder 9%;

[0037] SiO 2 Micropowder 3%;

[0038] Pure calcium aluminate cement 4%;

[0039] Heat resistant steel fibers 2%.

[0040] Al in the brown corundum 2 o 3 Content≥93%, Fe 2 o 3 ≤1.5%; Al in andalusite 2 o 3 Content ≥ 60%; SiC content ≥ 95% in SiC and SiC fine powder with a particle size of 1-3mm; Al in andalusite powder 2 o 3 Content ≥ 61%; Al in white corundum powder 2 o 3 Content ≥ 95%; α-Al 2 o 3 Al in micropowder 2 o 3 Co...

Embodiment 2

[0042] A wear-resistant castable for a cement kiln tertiary air duct elbow, the components of which are composed of:

[0043] Brown corundum with a particle size of 5-8mm 7%;

[0044] Brown corundum with a particle size of 3-5mm 25%;

[0045] Brown corundum with a particle size of 1-3mm 7%;

[0046] Brown corundum with a particle size of 0.088-1mm 16%;

[0047] SiC 14% with a particle size of 1-3mm;

[0048] SiC fine powder 7%;

[0049] White corundum powder 5%;

[0050]α-Al 2 o 3 Micropowder 7%;

[0051] SiO 2 Micropowder 5%;

[0052] Pure calcium aluminate cement 6%;

[0053] Heat-resistant steel fiber 1%;

[0054] The sum of the contents of the above components is 100%.

[0055] The above-mentioned wear-resistant castable for the tertiary air duct elbow of a cement kiln, in terms of mass ratio, its components also include polypropylene fiber and sodium tripolyphosphate. The specific content ratio is: the total content of the above components: polypropylene fiber...

Embodiment 3

[0058] A wear-resistant castable for a cement kiln tertiary air duct elbow, the components of which are composed of:

[0059] Brown corundum with a particle size of 3-5mm 25%;

[0060] Brown corundum with a particle size of 1-3mm 12%;

[0061] Brown corundum with a particle size of 0.088-1mm 10%;

[0062] Andalusite with a particle size of 0.088-1mm 8%;

[0063] SiC 12% with a particle size of 1-3mm;

[0064] SiC fine powder 4%;

[0065] Andalusite powder 2%;

[0066] White corundum powder 5%;

[0067] α-Al 2 o 3 Micropowder 9%;

[0068] SiO 2 Micropowder 3%;

[0069] Pure calcium aluminate cement 8%;

[0070] Heat-resistant steel fiber 2%;

[0071] The sum of the contents of the above components is 100%.

[0072] The above-mentioned wear-resistant castable for the tertiary air duct elbow of a cement kiln, in terms of mass ratio, its components also include polypropylene fiber and sodium tripolyphosphate. The specific content ratio is: the total content of the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com