Full-digital proportion integration differentiation (PID) controlled light-emitting diode (LED) light source driver

A technology of LED light source and LED drive, applied in the direction of light source, electric light source, lighting device, etc., can solve the problems of complex manufacturing process, inconvenient control and quantitative management of analog circuit, large size of driving circuit, etc., to ensure service life and reliability. , Easy to control and quantitative management, stable effect of drive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

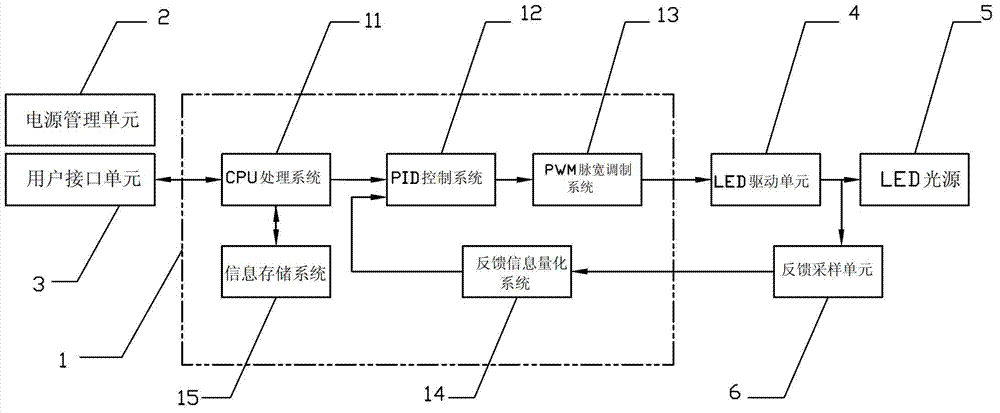

[0019] refer to figure 1 , an all-digital PID control LED light source driver of the present invention includes a user interface unit 3, a control processing unit 1, an LED drive unit 4, an LED light source 5 and a power management unit 2, wherein the core part of the control processing unit 1 includes an integrated single-chip microcomputer The CPU processing system 11, the PID control system 12, the PWM pulse width modulation system 13, the feedback information quantization system 14 and the information storage system 15 in it.

[0020] In the present invention, the control processing unit 1 performs information processing and control by means of a single-chip microcomputer, and writes a software PID controller through a software program, thereby realizing full-digital PID control. The PID control system 12 calculates the duty ratio data of the current modulation according to the given control amount and feedback amount, and transmits it to the PWM pulse width modulation sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com