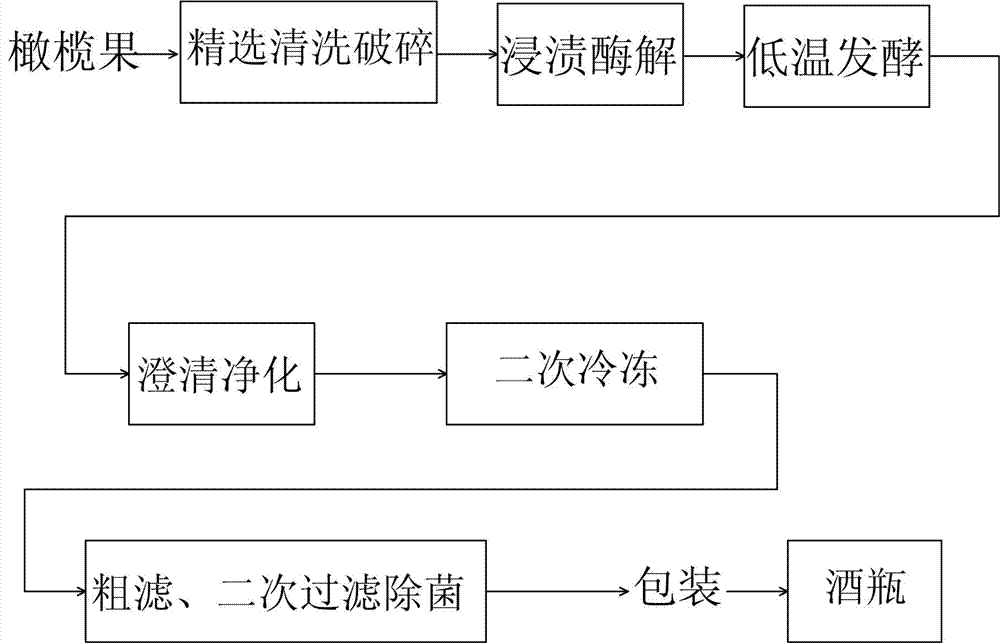

Production method of fermented olive wine and product thereof

A production method and olive wine technology are applied to the production of fermented olive wine and the product field thereof, which can solve the problems of poor taste, poor stability, insufficient aroma extraction and the like, and achieve good enzymatic hydrolysis effect and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] First of all, the raw olive fruit is selected, and the fresh fruit that is more than seven or eight mature is selected, and the rotten fruit, the fallen fruit, and the fruit that is too small and not mature enough are selected, and the qualified ones are thoroughly cleaned, and then crushed with a beater. And add SO at 30mg / L 2 , transfer the olive pulp into a temperature-controllable dipping tank, add pectinase 100 mg / L~150 mg / L, cellulase 500 mg / L~800 mg / L, stir evenly, and control the dipping temperature at 15°C~ 18°C, maintain for 6 hours to 10 hours. The juice yield can reach more than 45%, and the olive juice for fermentation can be obtained.

[0023] Transfer the clear juice of the above-mentioned fermented fruit juice to the fermenter, add activated Saccharomyces cerevisiae active dry yeast, add slowly at an amount of 150mg-250mg per liter of fermented fruit juice, stir evenly, and control the fermentation temperature at 15°C-20°C ℃, after 7 days to 10 days of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com