Preparation method and application of adjustable-refractivity silicon dioxide coated quantum dot nano composite luminescent material

A nano-composite, luminescent material technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of easy agglomeration, large particle size of phosphors, opaque composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

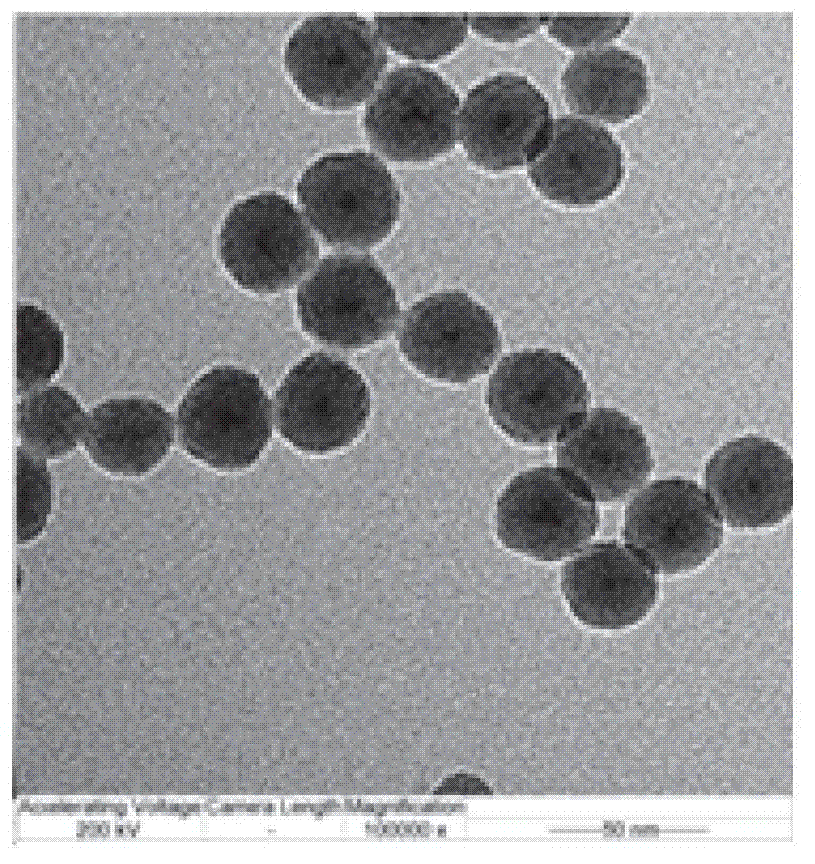

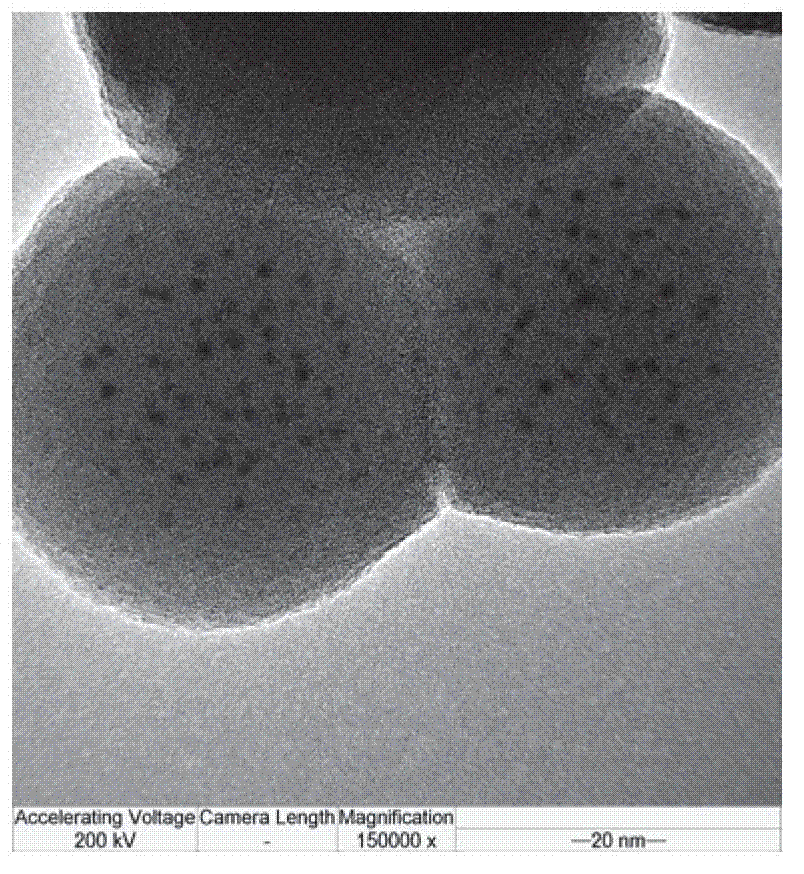

[0041] In this example, first prepare SiO 2 A nanocomposite luminescent material coated with quantum dots CdSe / CdS / ZnS, which consists of SiO 2 Composition of nanocomposite particles coated with quantum dots CdSe / CdS / ZnS, where each nanocomposite particle is SiO 2 Nanocomposite particles of CdSe / CdS / ZnS coated single quantum dots. Specific steps are as follows:

[0042] Step 1, dissolving quantum dots CdSe / CdS / ZnS in cyclohexane. Wherein, the quantum dot CdSe / CdS / ZnS is a quantum dot with a three-layer core-shell structure of CdSe / CdS / ZnS, and its luminous wavelength is 520nm. Quantum dots CdSe / CdS / ZnS were dissolved in cyclohexane to obtain a 10 mL, 1 mM solution.

[0043] Step 2: In the solution obtained in step 1, add TEOS (tetraethylorthosilicate), a surfactant and a catalyst to carry out catalyzed inverse microemulsion polymerization. In the present embodiment, the concrete steps that carry out the inverse microemulsion polymerization reaction of catalysis are:

[0...

Embodiment 2

[0053] In this example, first prepare SiO 2 A nanocomposite luminescent material coated with quantum dots Cu:CdS / ZnS, which is composed of SiO 2 Composition of nanocomposite particles coated with quantum dots Cu:CdS / ZnS, where each nanocomposite particle is SiO 2 Nanocomposite particles of CdSe / CdS / ZnS coated single quantum dots. Specific steps are as follows:

[0054] Step 1, the quantum dot Cu:CdS / ZnS is first dissolved in an organic reagent, and then dissolved in cyclohexane. Among them, the quantum dot Cu:CdS / ZnS is a quantum dot with a two-layer core-shell structure of Cu-doped CdS / ZnS, and its emission wavelength is 640nm; the organic reagent is n-hexane, and the amount of cyclohexane is 9mL. Quantum dots Cu:CdS / ZnS were dissolved in n-hexane to obtain a 10 mL, 1 mM solution, and the solution was mixed with cyclohexane.

[0055] Step 2, in the solution that step 1 obtains, add TEOS, surfactant and catalyst to carry out the inverse microemulsion polymerization reactio...

Embodiment 3

[0065] In this example, first prepare SiO 2 A nanocomposite luminescent material coated with quantum dots ZnSe, which consists of SiO 2 Composition of nanocomposite particles coated with quantum dots ZnSe, where each nanocomposite particle is SiO 2 Nanocomposite particles coated with single quantum dots ZnSe. Specific steps are as follows:

[0066] Step 1, the quantum dot ZnSe is first dissolved in an organic reagent, and then dissolved in cyclohexane. Among them, the emission wavelength of quantum ZnSe is 370nm; the organic reagent is toluene, and the amount of cyclohexane is 9mL. The quantum dot ZnSe was dissolved in toluene to obtain a 1 mL, 10 mM solution, and the solution was mixed with cyclohexane.

[0067] Step 2, in the solution that step 1 obtains, add TEOS, surfactant and catalyst to carry out the inverse microemulsion polymerization reaction of catalysis. In the present embodiment, the concrete steps that carry out the inverse microemulsion polymerization react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com