Antistatic polyethylene glycol terephthalate composite material

A technology of ethylene phthalate and composite materials, which is applied in the field of antistatic polyethylene terephthalate composite materials, can solve the problems of entering water and reducing the antistatic properties of polyester fibers, and achieves lasting effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

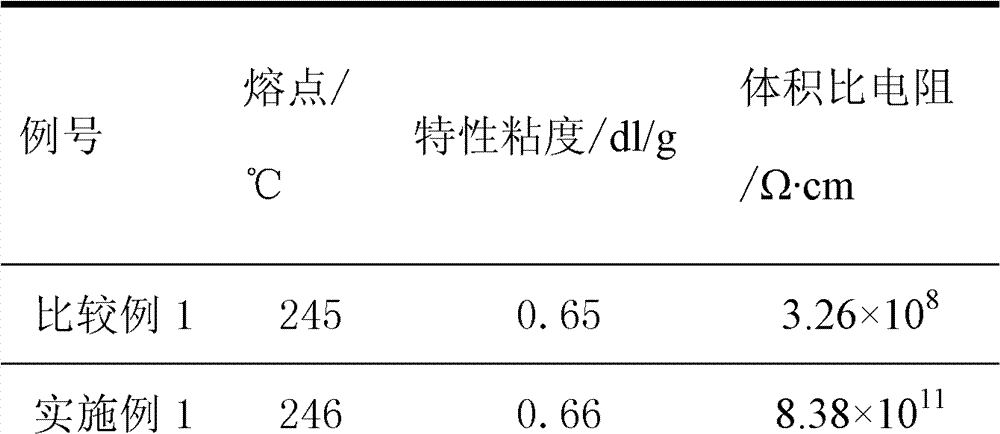

Embodiment 1

[0019] Add 1000 grams of purified terephthalic acid (PTA), 250 grams of ethylene glycol (EG), 280 grams of nanometer copper-ethylene glycol sol ( Wherein copper 20 grams, ethylene glycol is 260 grams), esterification reaction temperature is 250 ℃, reaction pressure is 0.26MPa, and reaction time is 110 minutes. The product of the above-mentioned esterification process is then subjected to a polycondensation process to form an antistatic PET composite material. Among them, the polycondensation reaction temperature in the low vacuum stage is 260°C, the pressure is gradually reduced from normal pressure to 1000Pa, the reaction time is 30 minutes, the polycondensation reaction temperature in the high vacuum stage is 275°C, the vacuum degree of the reaction system is 55Pa, and the reaction time is 82 minutes.

[0020] The melting point of the obtained polymer chips is 245° C., the intrinsic viscosity is 0.65 dL / g, and the volume specific resistance of the obtained fibers is 3.26×10 ...

Embodiment 2

[0025] Add 1000 g of purified terephthalic acid (PTA), 300 g of ethylene glycol (EG), and 230 g of nano-carbon black-ethylene glycol sol into a 5L stainless steel reaction kettle equipped with nitrogen inlet, condensate outlet and stirrer (Wherein carbon black 20 grams, ethylene glycol is 210 grams), esterification reaction temperature is 245 ℃, reaction pressure is 0.25MPa, and reaction time is 120 minutes. The product of the above-mentioned esterification process is then subjected to a polycondensation process to form an antistatic PET composite material. Among them, the polycondensation reaction temperature in the low vacuum stage is 255°C, the pressure is gradually reduced from normal pressure to 1000Pa, the reaction time is 25 minutes, the polycondensation reaction temperature in the high vacuum stage is 280°C, the vacuum degree of the reaction system is 50Pa, and the reaction time is 90 minutes.

[0026] The melting point of the obtained polymer chips is 246°C, the intri...

Embodiment 3

[0028] Add 1000 grams of purified terephthalic acid (PTA), 250 grams of ethylene glycol (EG), and 280 grams of nano-cuprous iodide-ethylenedioxide into a 5L stainless steel reaction kettle equipped with nitrogen inlet, condensate outlet and stirrer Alcohol sol (including 20 grams of cuprous iodide and 260 grams of ethylene glycol), the esterification reaction temperature is 250° C., the reaction pressure is 0.25 MPa, and the reaction time is 90 minutes. The product of the above-mentioned esterification process is then subjected to a polycondensation process to form an antistatic PET composite material. Among them, the polycondensation reaction temperature in the low vacuum stage is 200-240°C, the pressure is gradually reduced from normal pressure to 1000Pa, the reaction time is 30 minutes, the polycondensation reaction temperature in the high vacuum stage is 285°C, the vacuum degree of the reaction system is 50Pa, and the reaction time is 78 minute.

[0029] The melting point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Volume specific resistance | aaaaa | aaaaa |

| Specific resistance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com