Organic polymer gelator and preparation method and application thereof

A technology of gelling factor and polymer, applied in the field of its preparation, organic polymer gelling factor, can solve problems such as few reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

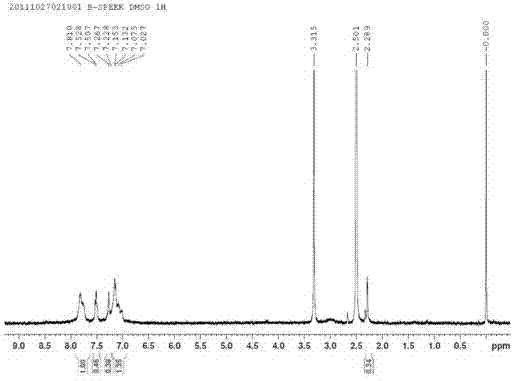

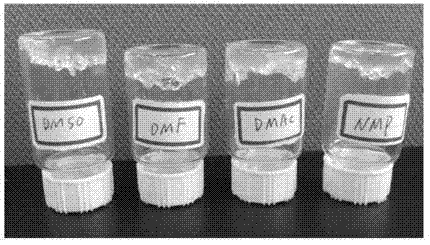

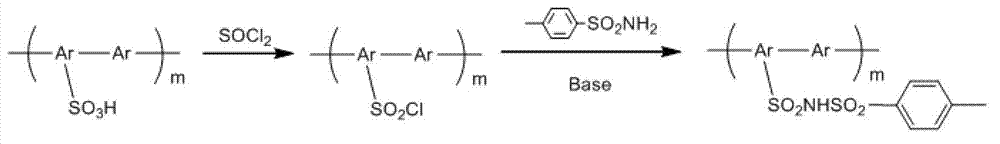

[0028] In this embodiment, the organic polymer gel factor is a polymer whose main chain is polyether ether ketone, and the side chain contains benzenesulfonimide groups. The synthesis method of the organic polymer gel factor includes the following steps.

[0029] Step 1: Dissolve 7.96g of sulfonated polyetheretherketone (DS=66%) in 50ml of thionyl chloride, slowly add 0.5ml of pyridine dropwise, and react at reflux temperature for 24h. After the reaction, mix the solution Pour into 1L of deionized water to precipitate a white solid, filter and wash with deionized water until neutral to obtain sulfonyl chloride polyether ether ketone;

[0030] Step 2: Dissolve 4.16g of sulfonyl chloride polyetheretherketone obtained in step 1 and 3.42g of p-toluenesulfonamide in 50ml of 1,2-dichloroethane, slowly add 3ml of triethylamine dropwise to it, at 60°C The mixture was reacted for 48 hours, then filtered, and washed successively with chloroform, hydrochloric acid solution and deionized ...

Embodiment 2

[0034] In this embodiment, the organic polymer gel factor is a polymer whose main chain is polyether ether ketone, and the side chain contains benzenesulfonimide groups. The synthesis method of the organic polymer gel factor includes the following steps.

[0035] Step 1: Dissolve 8.01g of sulfonated polyetheretherketone (DS=53%) in 50ml of thionyl chloride, slowly add 0.5ml of pyridine dropwise, and react at reflux temperature for 24h. After the reaction, mix The solution was poured into 1L of deionized water, a white solid was precipitated, filtered, washed with deionized water until neutral, and sulfonyl chloride polyether ether ketone was obtained;

[0036] Step 2: Dissolve 3.70 g of the sulfonyl chloride polyether ether ketone obtained in step 1 and 3.42 g of p-toluenesulfonamide in 50 ml of chloroform, slowly add 0.60 g of sodium hydroxide therein, and react at 60°C for 48 hours. Then, it was filtered and washed successively with chloroform, hydrochloric acid solution and...

Embodiment 3

[0039] In this embodiment, the organic polymer gel factor is a polymer whose main chain is polyether ether ketone, and the side chain contains benzenesulfonimide groups. The synthesis method of the organic polymer gel factor includes the following steps.

[0040] Step 1: Dissolve 8.24g of sulfonated polyetheretherketone (DS=74%) in 50ml of thionyl chloride, slowly add 0.5ml of pyridine dropwise, and react at reflux temperature for 24h. After the reaction, mix the solution Pour into 1L of deionized water to precipitate a white solid, filter and wash with deionized water until neutral to obtain sulfonyl chloride polyether ether ketone;

[0041] Step 2: Dissolve 3.90 g of the sulfonyl chloride polyether ether ketone obtained in step 1 and 3.42 g of p-toluenesulfonamide in 50 ml of dimethyl sulfoxide, add 0.73 g of potassium fluoride to it, and react at 60°C for 48 hours. Then, it was filtered and washed successively with chloroform, hydrochloric acid solution and deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com