Textile deepening agent and preparation method thereof

A technology of deepening agent and fabric, applied in the direction of animal fibers, textiles and papermaking, fiber processing, etc., can solve the problems of low deepening efficiency and difficult to evenly disperse particles, and achieve excellent deepening effect, color deepening, and easy industrialization. The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

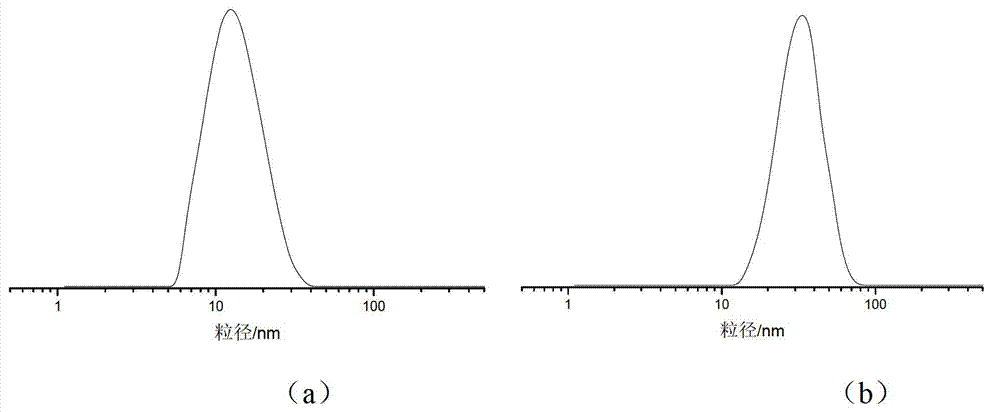

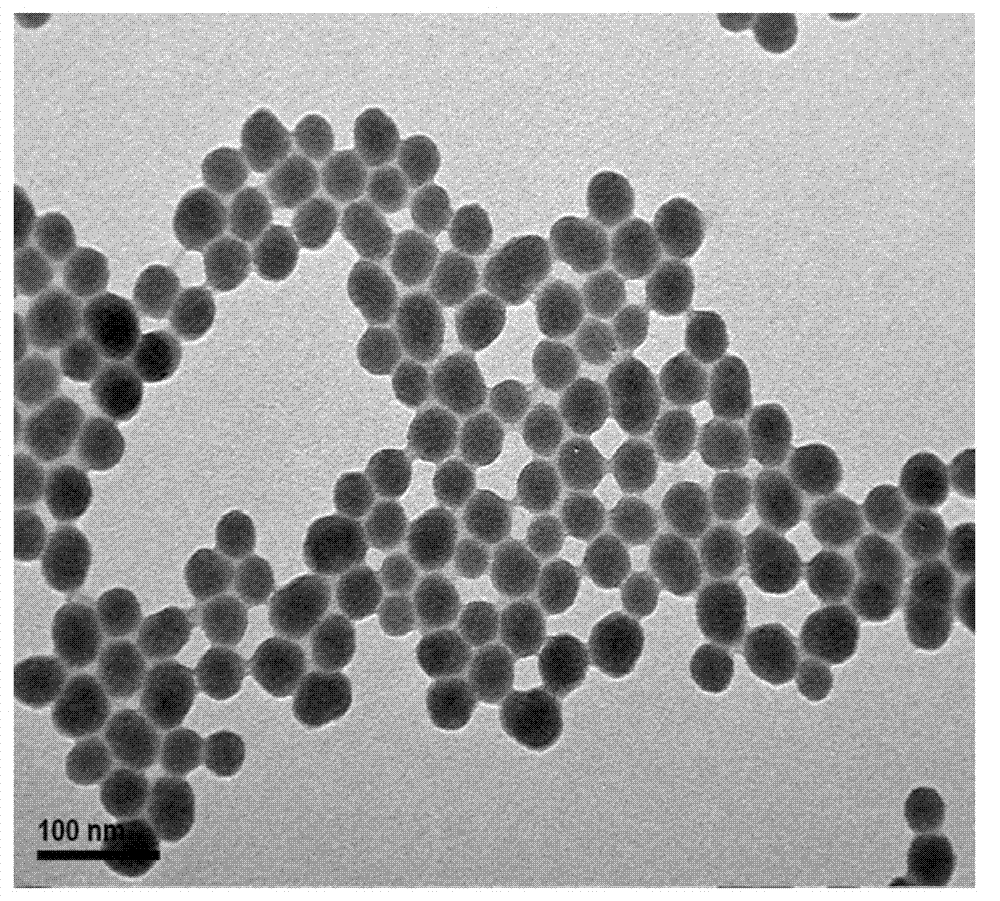

[0062] 1) Dissolve nano-silica with an average particle size of 15nm in ethanol to obtain a nano-silica ethanol dispersion with a weight percentage of nano-silica of 30%, and then add it to the nano-silica ethanol dispersion 3-(Methacryloyloxy)propyltrimethoxysilane (MPS), the mass ratio of the added MPS to the nano-silica ethanol dispersion is 15:100, react at 25°C for 24h, Obtaining a silane coupling agent modified nano-silica solution;

[0063] 2) Take 10.45g of the silane coupling agent-modified nano-silica solution in step 1), and use a rotary evaporator to replace the ethanol in the silane coupling agent-modified nano-silica solution in step 1) with 3.55 g methyl methacrylate (MMA) replacement, that is, use a rotary evaporator to remove the ethanol in the silane coupling agent modified nano-silica solution in step 1), and then add 3.55 g methyl methacrylate (MMA), Obtain modified nano silicon dioxide dispersion liquid;

[0064] Mix the modified nano-silica dispersion w...

Embodiment 2

[0071] 1) Dissolve nano-silica with an average particle size of 30nm in ethanol to obtain a nano-silica ethanol dispersion with a weight percentage of 2.5% nano-silica, and then add it to the nano-silica ethanol dispersion Vinyl triethoxysilane (A-151), the mass ratio of A-151 added to the nano-silica ethanol dispersion is 10:100, react at 25°C for 24h to obtain a silane coupling agent Modified nano silica solution;

[0072] 2) Take 10.025g of the silane coupling agent-modified nano-silica solution in step 1), and use a rotary evaporator to replace the ethanol in the silane coupling agent-modified nano-silica solution in step 1) with 3.725 g methyl methacrylate (MMA) replacement, that is, use a rotary evaporator to remove the ethanol in the silane coupling agent modified nano-silica solution in step 1), and then add 3.725 g methyl methacrylate (MMA), Obtain modified nano silicon dioxide dispersion liquid;

[0073] Mix the modified nano-silica dispersion with 0.25g of methyl ...

Embodiment 3

[0077] 1) Dissolve nano-silica with an average particle size of 70nm in ethanol to obtain a nano-silica ethanol dispersion with a weight percentage of 24% nano-silica, and then add it to the nano-silica ethanol dispersion Vinyltrimethoxysilane (A-171), the mass ratio of A-171 added to the nano-silica ethanol dispersion is 8:100, react at 25°C for 24h to obtain a silane coupling agent Modified nano silica solution;

[0078] 2) Take 10.192g of the silane coupling agent-modified nano-silica solution in step 1), and use a rotary evaporator to replace the ethanol in the silane coupling agent-modified nano-silica solution in step 1) with 3.408 g methyl methacrylate (MMA) replacement, that is, use a rotary evaporator to remove the ethanol in the silane coupling agent modified nano-silica solution in step 1), and then add 3.408 g methyl methacrylate (MMA), Obtain modified nano silicon dioxide dispersion liquid;

[0079] Mix the modified nano-silica dispersion with 1.4g of methyl met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com