Use of artemisia annua and artemisia annua industrial-extraction residues as raw materials for caffeoylquinic acid preparation

A technology for caffeoylquinic acid and Artemisia annua is applied in the application field of preparing caffeoylquinic acid raw materials, and can solve the problems of industrial separation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

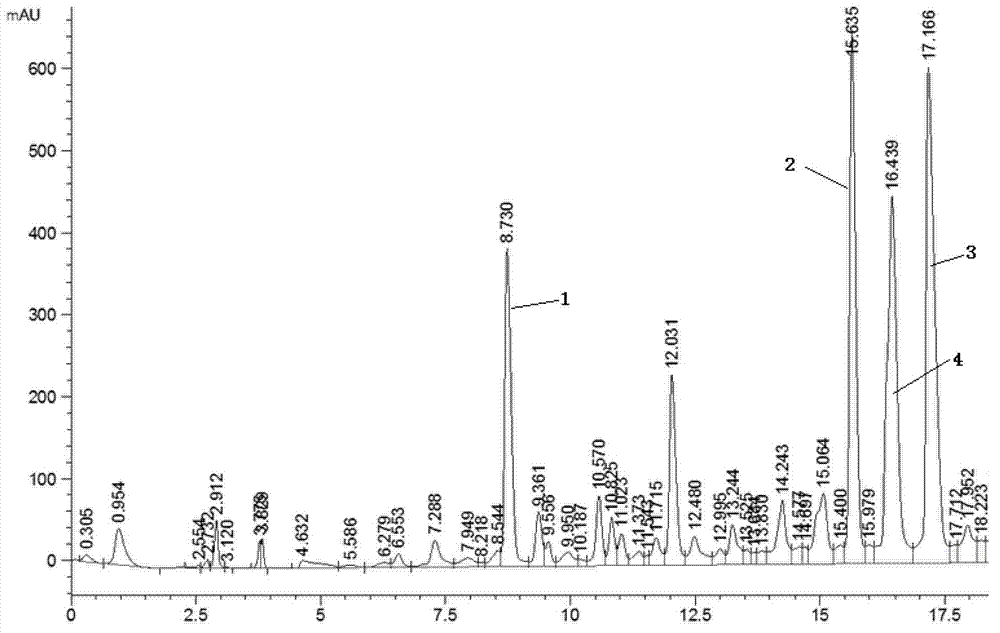

[0020] Take 100g of the industrial extraction residue of Artemisia annua after extracting artemisinin with petroleum ether, add it into a solution with pH=1.0, n-butanol:water=9:1 at a solid-to-liquid ratio of 1:5 (w / w), and ultrasonically Leaching under action for 10 hours, after solid-liquid separation, the extract containing caffeoylquinic acid was obtained, and detected by high performance liquid chromatography, wherein the species of caffeoylquinic acid is shown in figure 1 .

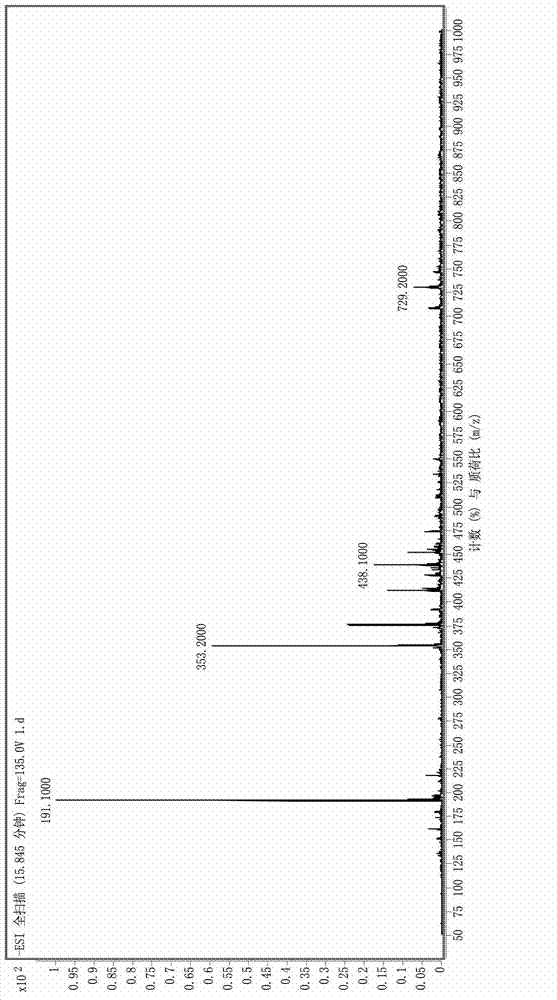

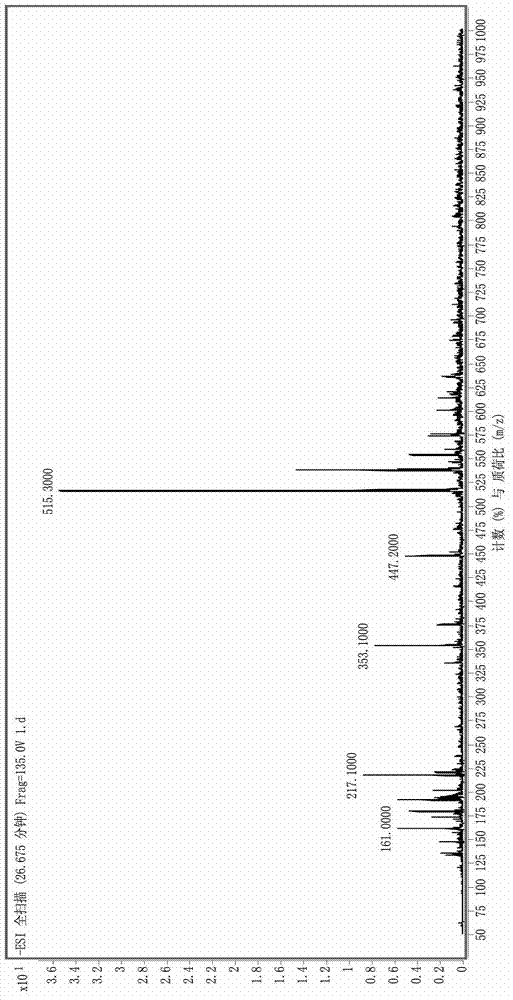

[0021] 3.5g of caffeoylquinic acid with a purity of 61% was obtained by liquid-liquid extraction, and then 1.5g of caffeoylquinic acid with a purity of 94% was obtained through chromatography column separation and purification. Detected by liquid chromatography-mass spectrometry, 5-0 The mass spectrum (MS) of monocaffeoylquinic acid and the mass spectrum (MS) of 3,5-dicaffeoylquinic acid are shown in figure 2 and image 3 shown.

Embodiment 2

[0023] Take 100 g of industrial extraction residue of Artemisia annua after extracting artemisinin with a mixture of petroleum ether, chloroform and toluene, add it to the aqueous solution with pH=7.0 at a solid-to-liquid ratio of 1:60 (w / w), and extract in countercurrent for 9 hours. After solid-liquid separation, an extract containing caffeoylquinic acid was obtained, and 3.8 g of caffeoylquinic acid with a purity of 55% was obtained through liquid-liquid extraction, and then 1.6 g of caffeoylquinic acid with a purity of 92% was obtained through chromatography column separation and purification Nicotinic acid.

Embodiment 3

[0025] Take 100g of the Artemisia annua raw material, add it into the solution of pH=4.0 ethanol:water=5:1 according to the solid-liquid ratio of 1:10 (w / w), extract under the action of ultrasound for 5 hours, and obtain the coffee-containing The extract of caffeoylquinic acid was separated by liquid-liquid extraction to obtain 6.8 g of caffeoylquinic acid with a purity of 60%, and then separated and purified by a chromatographic column to obtain 3.7 g of caffeoylquinic acid with a purity of 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com