Dual organic modified cement-base expanded perlite fireproof thermal-insulation board and preparation method thereof

A technology of expanded perlite and fireproof thermal insulation board is applied in the field of double organic modified cement-based expanded perlite fireproof thermal insulation board and its preparation, which can solve the problems of low density and low elastic modulus, and achieve low elastic modulus and use Long life and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

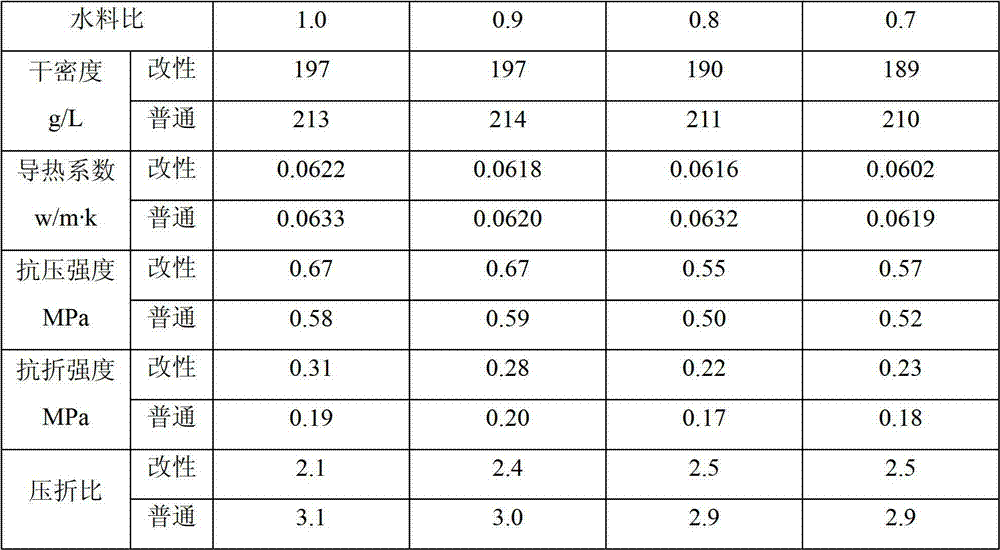

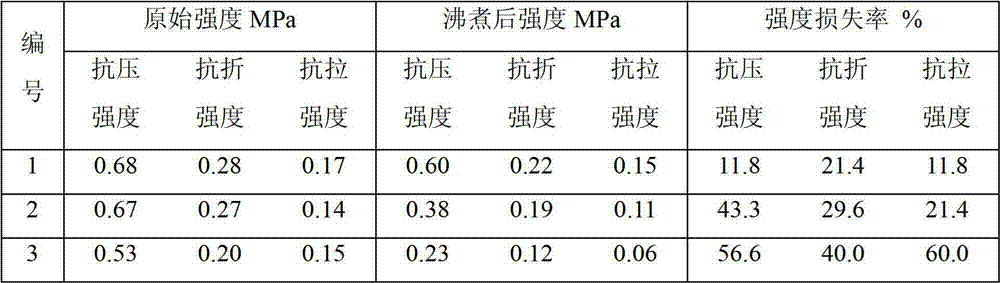

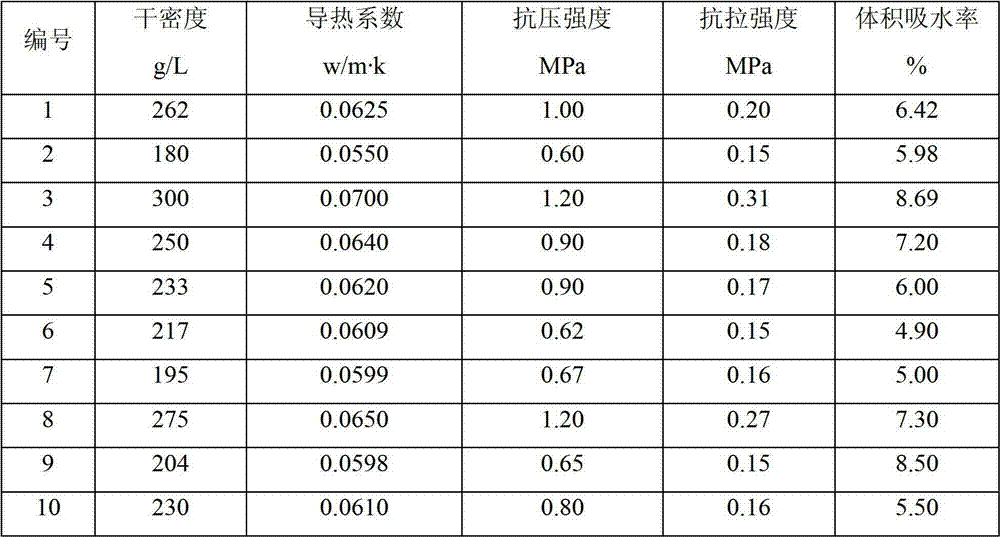

Method used

Image

Examples

Embodiment 1

[0038] Take each raw material by the following weight: 52.5 grade cement 20kg, bulk density is 70kg of organically modified expanded perlite of 80g / L, active filler silica powder 2kg, polymer emulsion 7.4kg, additive superplasticizer 0.6kg; After the above raw materials are mixed evenly, 60kg of water is added, stirred into a semi-dry material by a self-falling mixer, filled into a mold, and pressed into a fireproof insulation board with a compression ratio of 1.8 by a pressing plate equipment, and obtained after several hours of high-temperature steam curing. finished product.

Embodiment 2

[0040] Take each raw material by the following weight: 52.5 grade cement 25kg, bulk density is 65kg of organically modified expanded perlite of 75g / L, active filler fly ash 1kg, polymer emulsion 9kg, additive early strength agent 1kg; After mixing evenly, add 45kg of water, stir it into a semi-dry material with a self-falling mixer, fill it into a mold, and use a pressing plate equipment to press it into a fireproof insulation board with a compression ratio of 2.5. After several hours of high-temperature steam curing, the finished product is obtained.

Embodiment 3

[0042] Take each raw material by the following weight: 15kg of 52.5 grade cement, 80kg of organically modified expanded perlite with a bulk density of 100g / L, 4.6kg of polymer emulsion, and 0.4kg of additive water repellent; after mixing the above raw materials uniformly, add 55kg of water is stirred into a semi-dry material by a self-falling mixer, filled into a mold, and pressed into a fireproof insulation board with a compression ratio of 1.5 using a pressing plate equipment, and the finished product is obtained after several hours of high-temperature steam curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com