Machining method of two-sided angle counter bit for titanium alloy

A processing method and titanium alloy technology, applied in the processing field of countersinking drills, can solve the problem of inability to clamp, and achieve the effects of reducing waste, improving capacity and saving outsourcing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

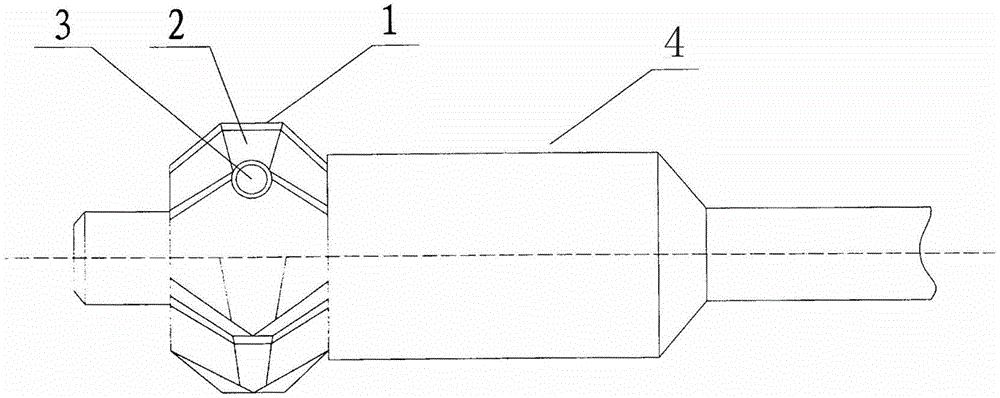

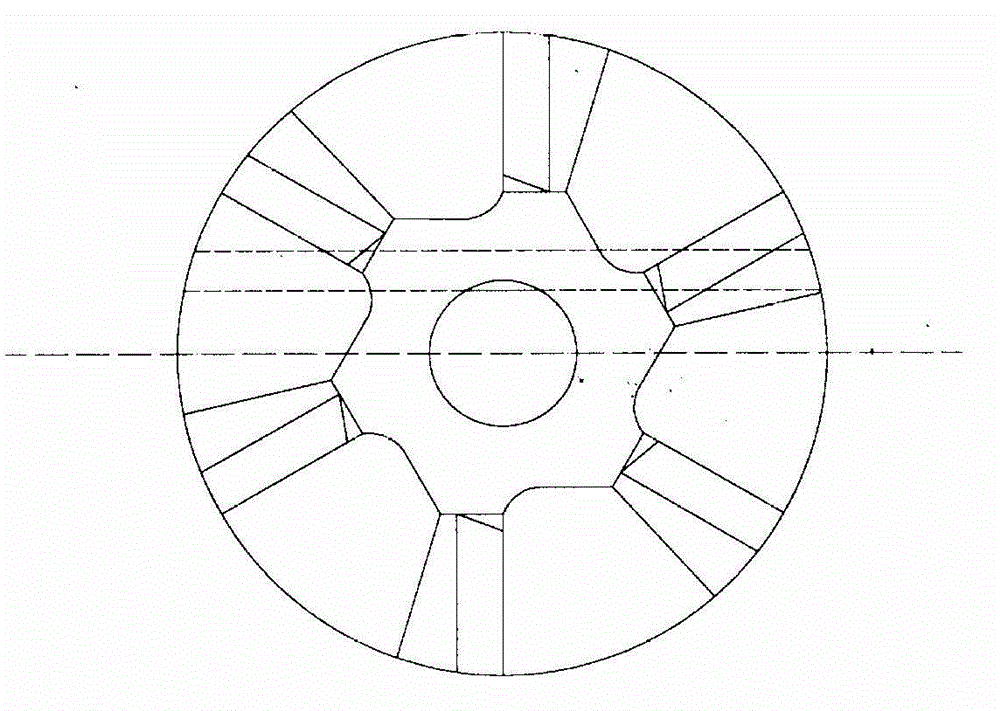

[0031] Such as figure 1 and figure 2 As shown, the titanium alloy is countersinking with double-sided angle, the cutter body is fixed on the cutter body with pins, and the blade is installed on the cutter body. The specific processing method is as follows:

[0032] 1) Cutting material: select materials according to the size of the cutter body, each end of which is lengthened by 20-30mm, and the diameter of the front-end extension part is 1-2mm larger than the diameter of the inner hole of the double-sided angle countersink drill, and the diameter of the rear-end extension part The diameter of the inner hole is 1-2mm smaller than that of the double-sided angle countersink;

[0033] 2) Turning shape: fix the extended part and the cutter body on the lathe, leave 0.6-0.7mm for the outer circle according to the size requirements, and turn the angled surface;

[0034] 3) The cutting edge of the knife body reaches the size requirement, and the extended part of the knife body is ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com