Deep-groove narrow-gap manual argon arc sealing welding method

A welding method and narrow gap technology, applied in manual argon arc sealing and sealing welding, manual argon arc sealing welding, can solve the problems of poor weld quality, incomplete penetration, incomplete fusion, etc., and achieve good welding quality and good weld bead The effect of small gaps and less filler metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Manual tungsten argon arc sealing welding of tube plate and heat exchange tube of a shell-and-tube heat exchanger

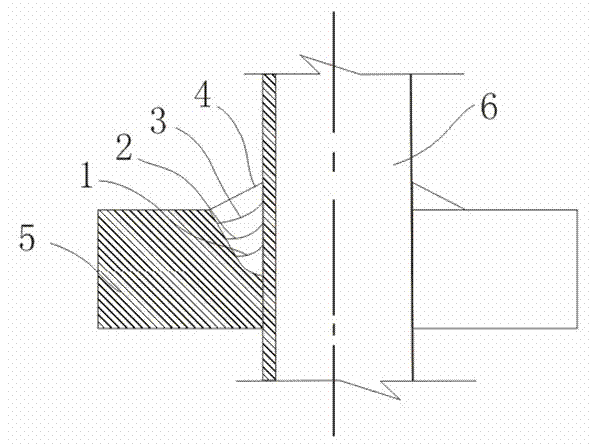

[0030] Such as figure 1 as shown,

[0031] The tube sheet 5 of the shell heat exchanger is made of Q245R, with a thickness of 34mm; the material of the heat exchange tube 6 is 20G, and the specification is φ38mm;

[0032] The specific sealing welding method of tube sheet and heat exchange tube is as follows:

[0033] 1) Preparation before welding: Select the diameter and shape of the ceramic nozzle of the welding torch according to the size and depth of the groove. The ceramic nozzle can extend into the groove and be about 10-12mm away from the root of the weld. In this embodiment, the model of the selected ceramic nozzle is : M10×45×6mm. In addition, it is also necessary to pay attention to the size of the magnetic mouth so as not to affect the operator’s line of sight.

[0034] Selection of tungsten electrode: thoriated tungsten WCe-20 with a diameter...

Embodiment 2

[0043] Manual tungsten argon arc sealing welding of tube plate and heat exchange tube of a shell-and-tube heat exchanger

[0044] The tube sheet 5 of the shell heat exchanger is made of Q245R, with a thickness of 38mm; the material of the heat exchange tube 6 is 20G, and the specification is φ43mm; the heat exchange tube 6 and the tube sheet 5 are welded vertically.

[0045] The specific sealing welding method of tube sheet and heat exchange tube is as follows:

[0046] 1) Preparation before welding: Select the diameter and shape of the ceramic nozzle of the welding torch according to the size and depth of the groove. The ceramic nozzle can extend into the groove and be 12mm away from the root of the weld. In this embodiment, the model of the selected ceramic nozzle is: M10× 45×6mm. In addition, it is also necessary to pay attention to the size of the magnetic mouth so as not to affect the operator's line of sight.

[0047] Selection of tungsten electrode: thoriated tungsten WC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com