Electric heating furnace

An electric heating furnace, furnace body technology, applied in electric heating systems, household heating, space heating and ventilation details, etc., can solve problems such as increased carbon emissions, heat waste, high temperature and high heat, etc. Small and compact size, the effect of reducing manufacturing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

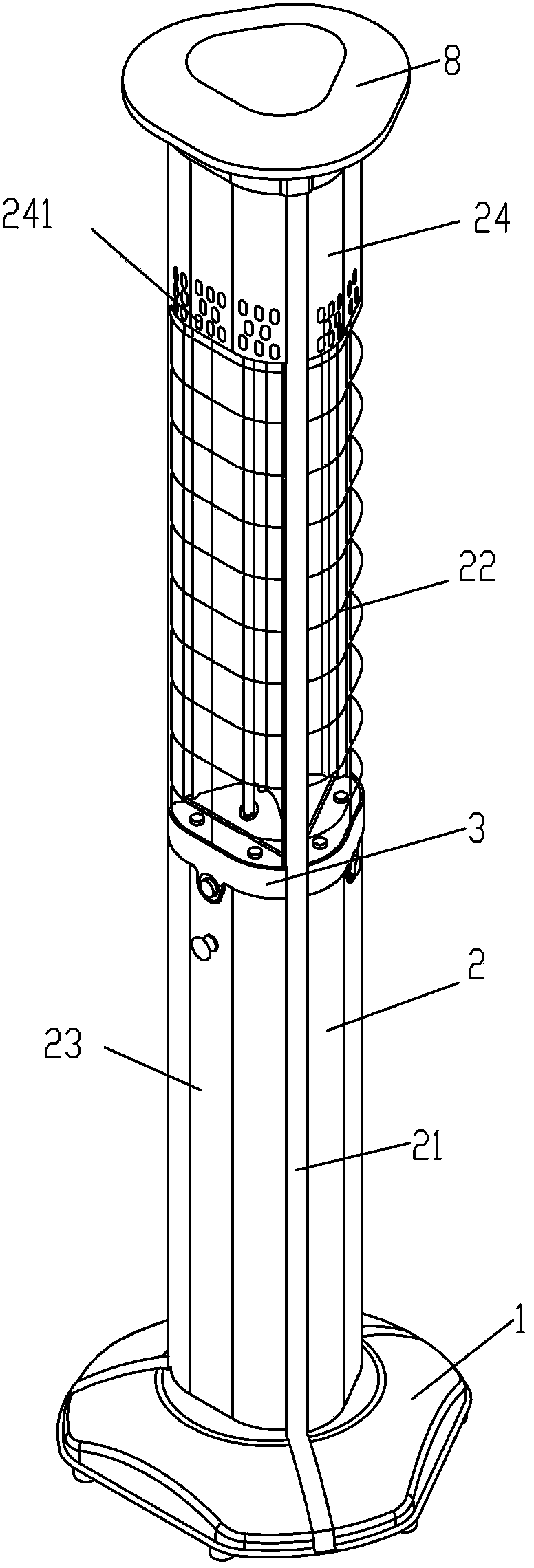

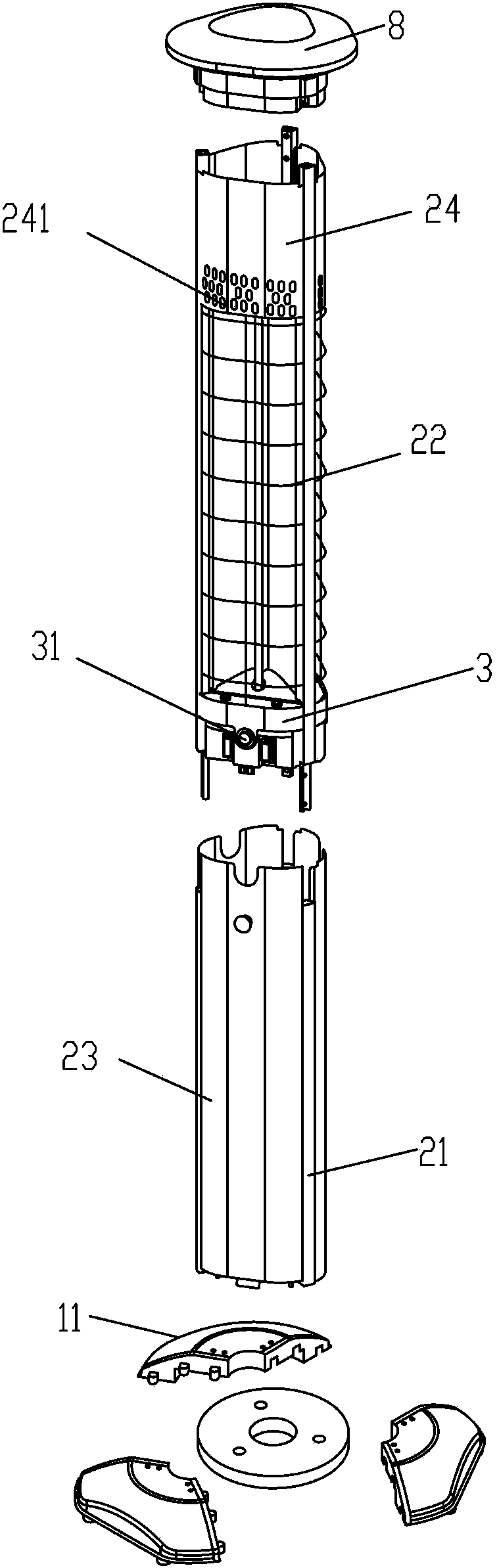

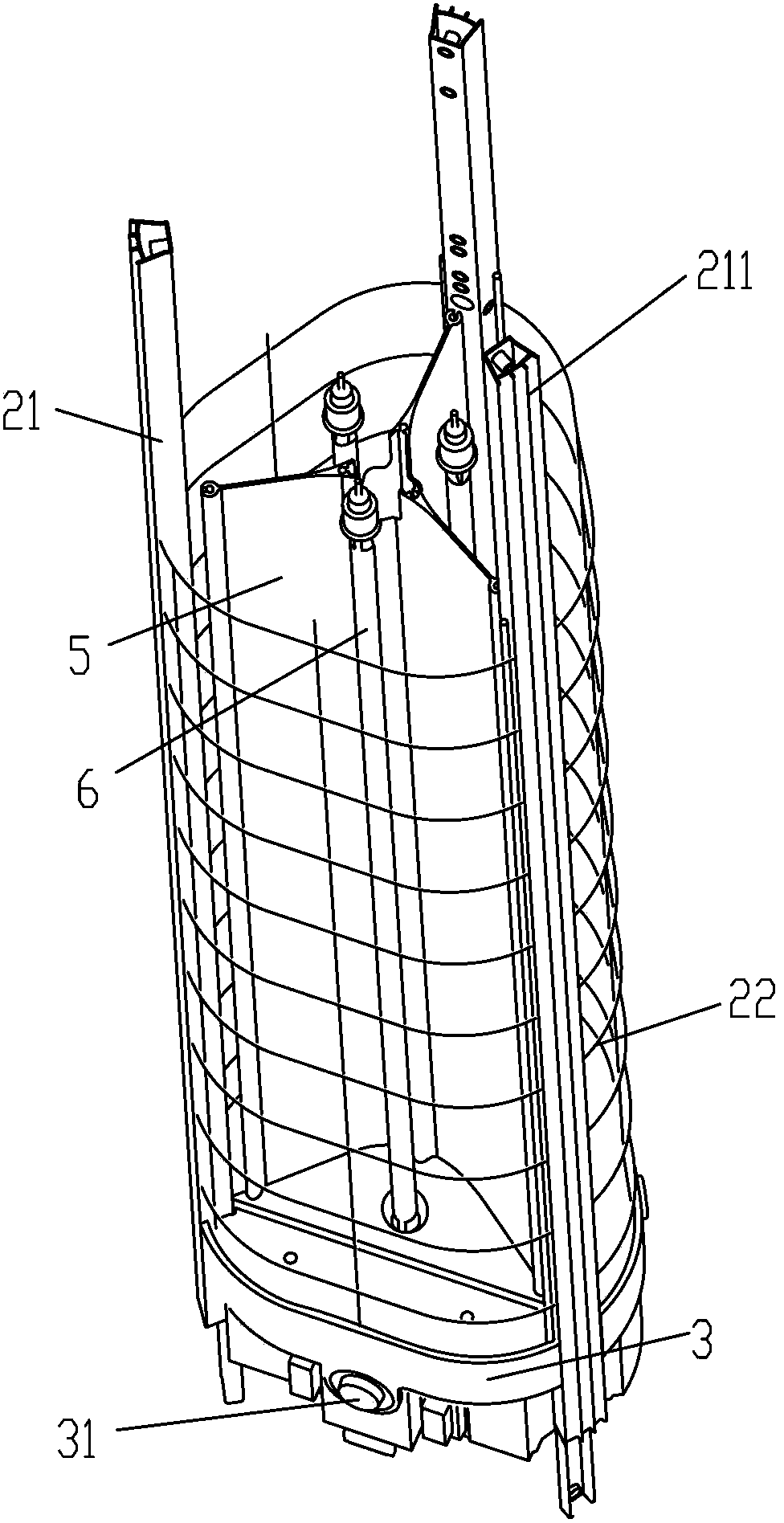

[0016] refer to Figure 1~Figure 4 , an electric heating furnace, comprising a base 1, a furnace body 2 is arranged on the base 1, the furnace body 2 includes a plurality of supporting columns 21, a protective net 22 is installed between the supporting columns 21, and a support is fixedly arranged in the furnace body A seat 3, the support 3 is provided with a lower support plate 41, the upper part of the furnace body is provided with an upper support plate 42, and a reflector 5 with a plurality of reflective surfaces is fixedly installed between the upper and lower support plates 41 and 42, The plurality of reflectors are distributed around the center of the reflector in a divergent shape, and a heat pipe 6 is fixedly installed in front of each reflector; reflectors 7 are arranged above and below the heat pipe 6, and the reflectors 7 are respectively fixed on the upper and lower sides of the reflector. On the lower support plates 42, 41, this design enables the heat generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com