Method For Dissolving Hyaluronic Acid And/or A Salt Thereof

A technology of hyaluronic acid and normal saline, applied in chemical instruments and methods, biochemical equipment and methods, dissolution, etc., can solve problems such as insufficient hyaluronic acid and decrease in molecular weight of hyaluronic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] 1,580 g of sodium hyaluronate with a molecular weight of 2.37 million obtained by fermentation using Streptococcus equi FM-100 (Weigongyan Junji No. 9027) was filled in a 20 L airtight container with a butterfly valve. Install a dispersing turbine-type stirring paddle in a 200L capacity stainless steel stirring tank with a Teflon coating on the inner surface, add 149L of physiological saline solution (solution for injection) containing 2mM sodium phosphate buffer solution at pH 7.3, and stir groove.

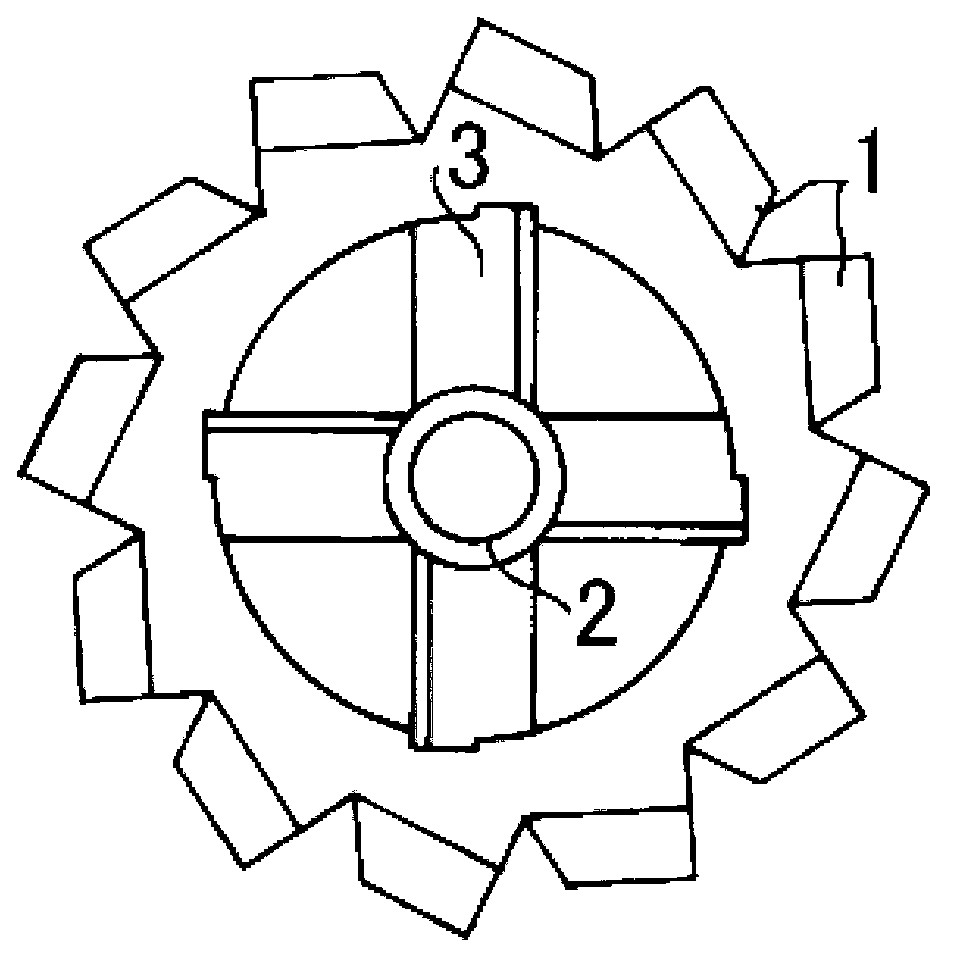

[0072] The airtight container filled with the aforementioned sodium hyaluronate is reversely installed on the raw powder input port of the stirring tank, the butterfly valve is opened, and the sodium hyaluronate is put into the stirring tank. exist Figure 1~2 The figure shows the top view of the dispersing turbine stirring paddles (consisting of 12 paddles with a diameter of 275 mm in the dissolver and 6 paddles with inclined blades).

[0073] Stirring was performed at ...

Embodiment 2

[0080] The configuration of the agitator in the agitation tank was changed variously to find the optimum agitation blade and agitation conditions, and a dissolution test was performed. In the dissolution test, 1580 g of sodium hyaluronate (limited viscosity: 35.0 dL / g) was added to a stirring tank with an inner diameter of 550 mm in which 149 L of physiological saline was added, and the mixer was operated to dissolve it. Regarding the results of the dissolution test, the dispersibility of sodium hyaluronate, whether it can be dissolved, and the decrease in molecular weight were evaluated according to the respective criteria described below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com