Electronic equipment

A technology of electronic equipment and electronic components, applied in the field of electronic equipment using heat pipes for heat dissipation, can solve the problems of increased heating power and power density of electronic equipment, structure and performance that cannot meet the heat dissipation requirements of thin electronic products, etc., to ensure heat transfer , Conducive to design and save volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

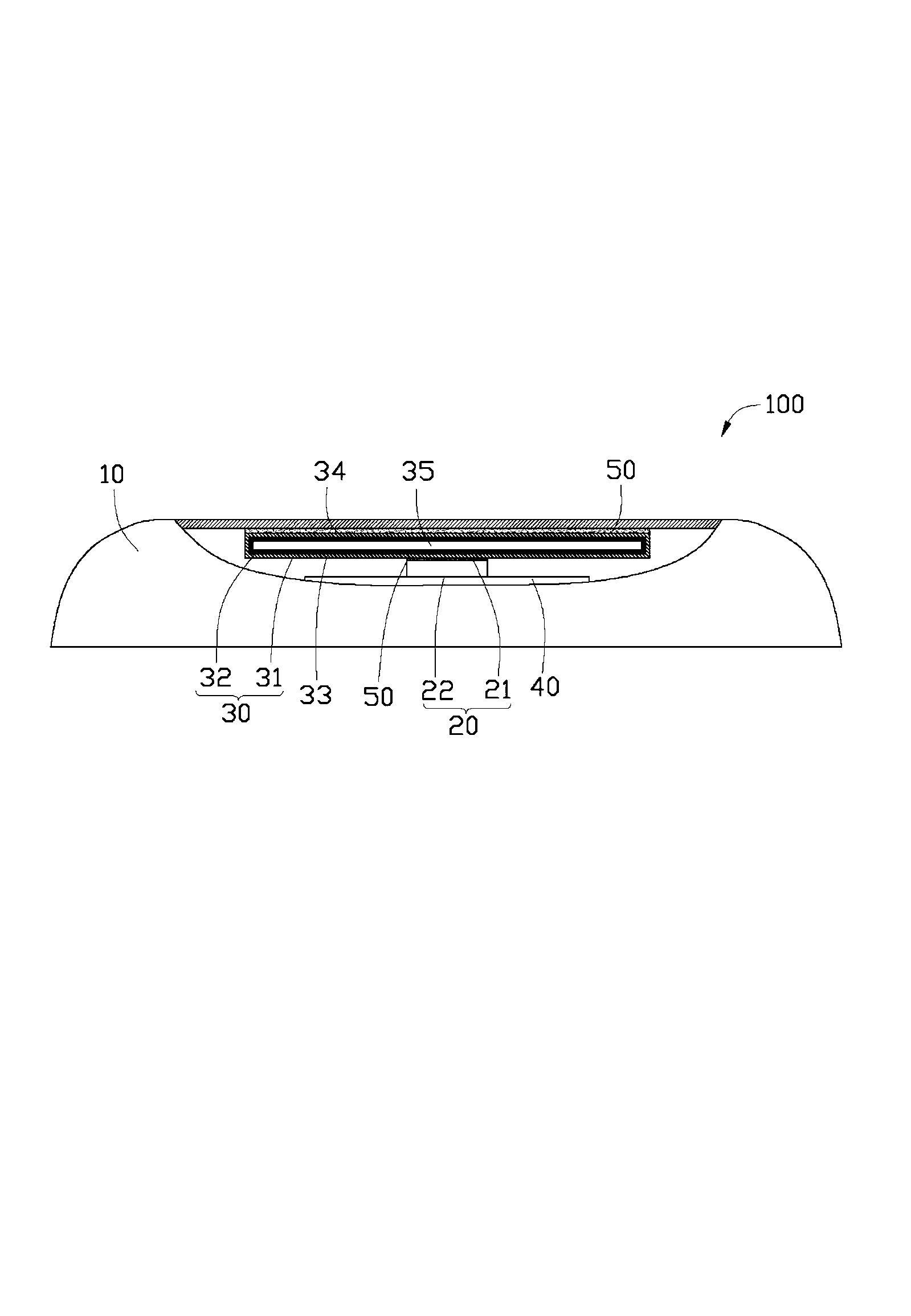

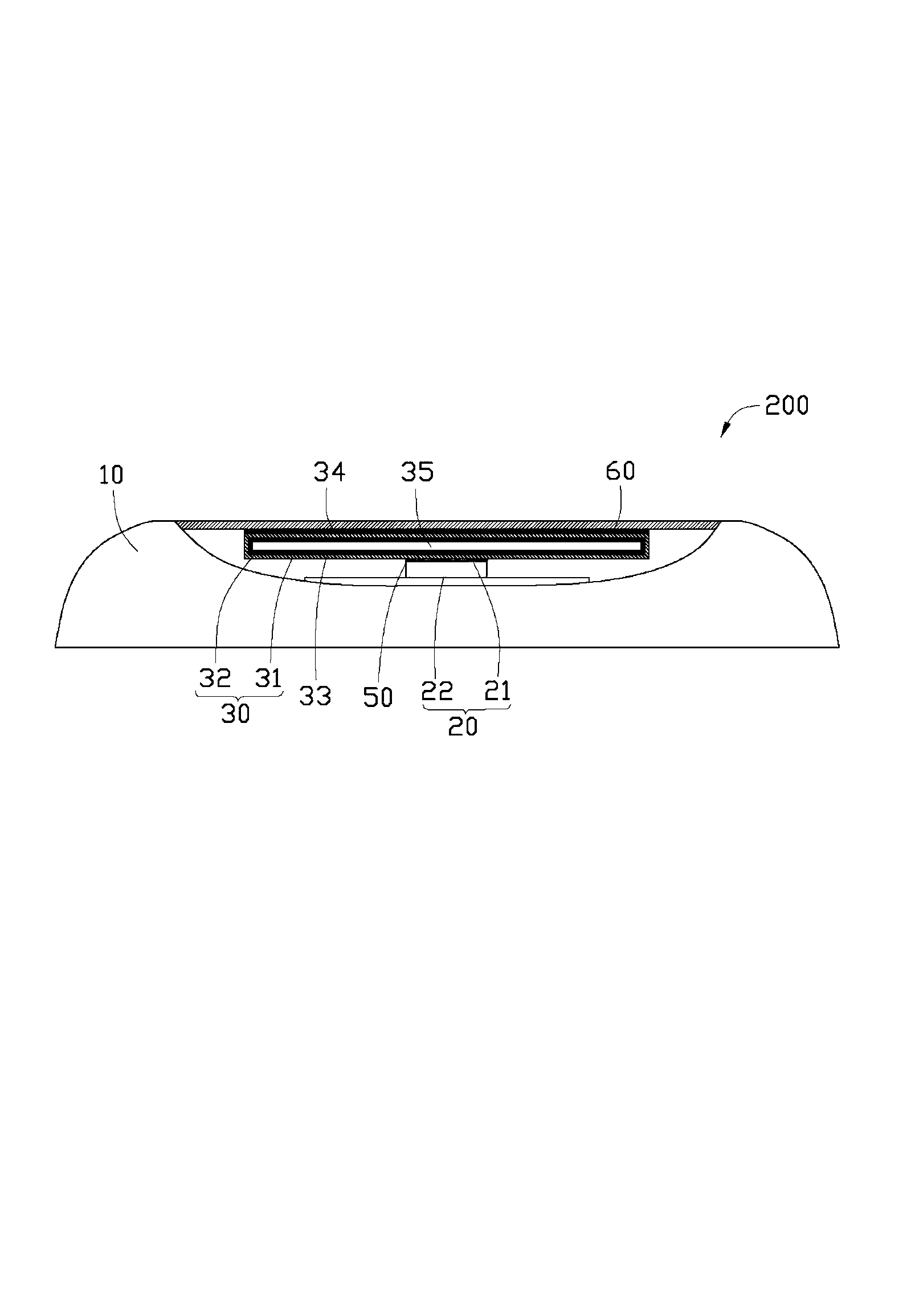

[0012] Please refer to figure 1 The electronic device 100 provided by the first embodiment of the present invention includes a casing 10, a heating electronic component 20 installed in the casing 10, and a flat plate installed in the casing 10 for dissipating the heat generated by the heating electronic component 20. The heat pipe 30 and the circuit board 40 carry the heat-generating electronic components 20 and provide power. The electronic device 100 may be a thin product such as a tablet computer, a smart phone, an all-in-one machine, a camera, etc. In this embodiment, the electronic device 100 is a tablet computer.

[0013] The casing 10 is the casing of the electronic device 100 and is used to protect the components inside the electronic device 100 , such as the circuit board 40 , the heating electronic components 20 and so on.

[0014] The heating electronic component 20 is a plate-shaped electronic component, such as a CPU of a tablet computer. The heating electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com