Niobium microalloying Mn-B series super-strength steel plate and heat treatment process thereof

A micro-alloying and ultra-high-strength technology, which is applied in the field of material heat treatment, can solve the problems of niobium micro-alloyed boron steel production and heat treatment processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

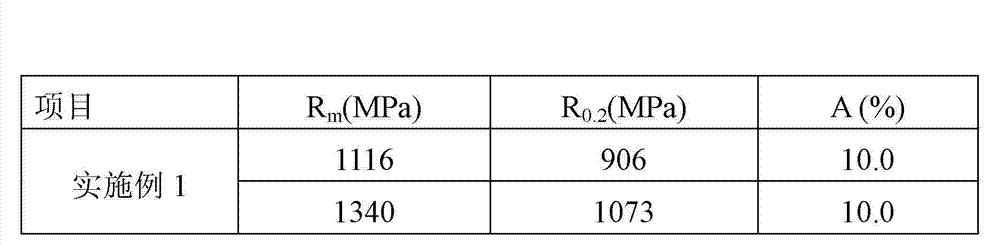

Embodiment 1

[0009] The thickness of the steel plate is 8mm, and its heat treatment process system is: austenitizing temperature 900°C, water quenching after holding time for 45 minutes. Temper at low temperature at 200°C, hold for 5 hours, and air cool. Sampling and testing, the mechanical properties testing values are shown in Table 1.

[0010]

[0011] Table 1 Tested values of mechanical properties

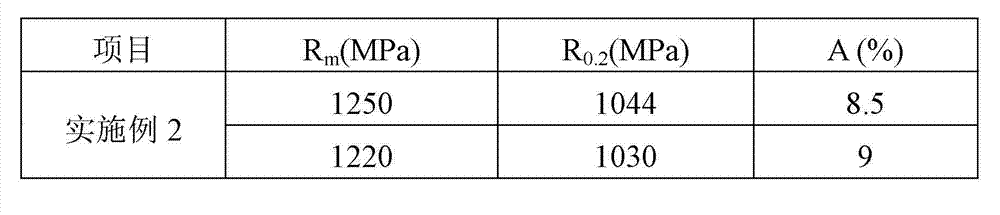

Embodiment 2

[0013] The steel plate thickness is 8mm, and its heat treatment process system is: austenitizing temperature 910 ℃, water quenching after holding time for 45 minutes. Temper at low temperature at 200°C, hold for 5 hours, and air cool. Sampling and testing, the mechanical properties test values are shown in Table 2.

[0014] Table 2 Tested values of mechanical properties

[0015]

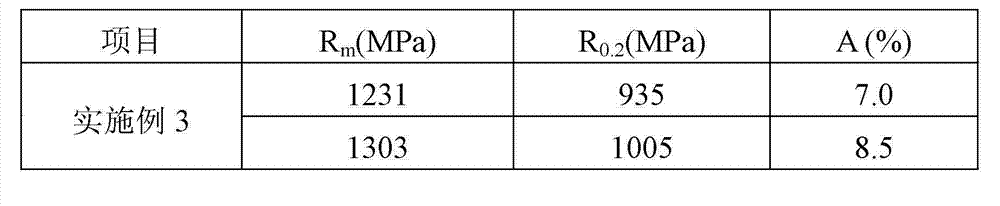

Embodiment 3

[0017] The thickness of the steel plate is 8mm, and its heat treatment process system is: austenitizing temperature 920°C, water quenching after holding time for 45 minutes. Temper at low temperature at 200°C, hold for 5 hours, and air cool. Sampling and testing, the mechanical properties test values are shown in Table 3.

[0018] Table 3 Tested values of mechanical properties

[0019]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com