Steelmaking slag former and preparation method thereof

A steel-making slag-forming agent and slag technology, which is applied in the direction of improving process efficiency, can solve the problems of increasing molten steel temperature drop and affecting steelmaking production, etc., achieves fast melting speed, reduces molten steel temperature drop and energy consumption, and reduces ton The effect of steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

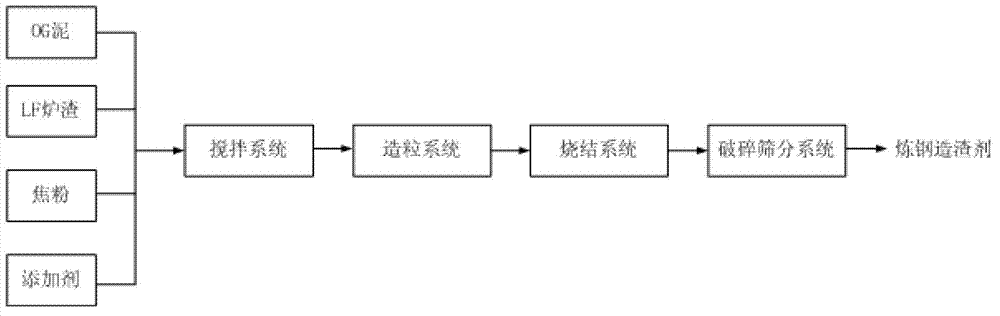

[0015] The various raw materials are formulated according to the following weight percentages: 70% of OG mud, 22% of steelmaking LF slag, 6% of coke powder, and 2% of binder. First use a twin-shaft mixer to mix the weighed various raw materials, and then enter the disc granulator for granulation. During the granulation process, the amount of water sprayed is 3-5% of the total weight of the raw materials. The finished pellets are dried in a belt dryer, and then sieved by a vibrating screen. The mesh diameter of the vibrating sieve is 7mm. Particles above 7mm are crushed by a crusher and then continue to enter the above-mentioned vibrating screen for screening. Particles below 7mm are dried and sent to the sintering machine for sintering. After the sintered intermediate material is crushed and screened, it becomes a block of 10~50mm, which is used as a slagging agent for steelmaking. The sintering temperature is controlled at 1000~1100°C. The belt dryer uses sintering flue g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com