Wool bright yellow active dye and preparation method thereof

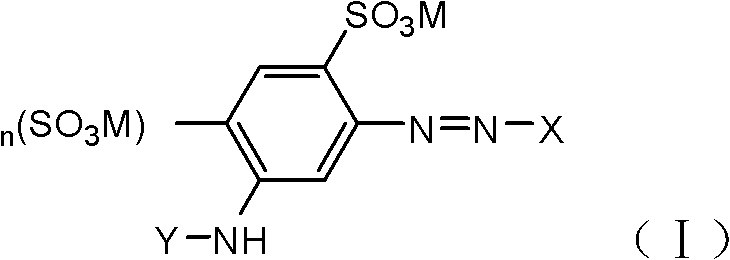

A reactive dye and bright yellow technology, applied in reactive dyes, dyeing methods, organic dyes, etc., can solve the problems of cumbersome steps, difficult to obtain small dyes, environmental pollution, etc., achieve high color fixation rate, broad commercialization prospects, high quality The effect of dyeing rate and color fixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

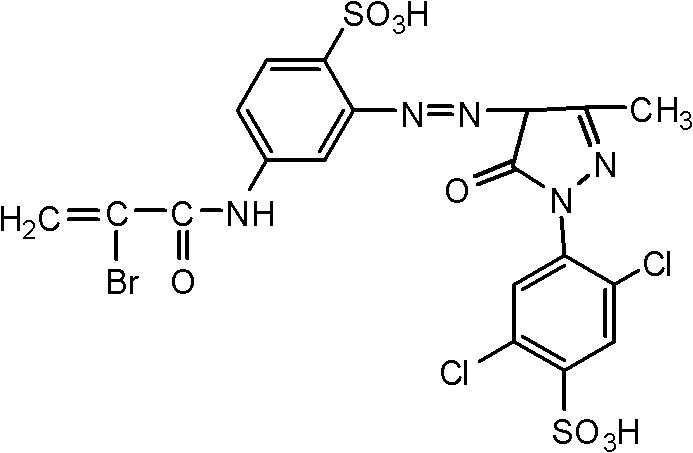

[0045] The preparation of embodiment 1 dyestuff (1)

[0046]

[0047] Dissolve 2.1 parts of 2,4-diaminobenzenesulfonic acid in 30 parts of water, cool in an ice-water bath, control the solution temperature between 0-5°C, add 2.5 parts of 2,3-dibromopropionyl chloride, and The pH of the reaction solution was adjusted by sodium to be between 6-7, and the reaction was continued for 1 hour. The end point of the reaction was detected by HPLC.

[0048] Add 2 parts of 30% hydrochloric acid to the above solution, control the temperature of the reaction solution at 5-10° C., and add 0.67 parts of sodium nitrite. Keep the temperature between 10-15°C and react for 2 hours.

[0049] After the diazotization reaction, use sulfamic acid to eliminate excess nitrous acid, and then add it to the completely dissolved 1-(4-sulfonic acid phenyl)-3-carboxy-5-pyrazolone solution [Disperse 2.7 parts of 1-(4-sulfophenyl)-3-carboxy-5-pyrazolone in 30 parts of water, adjust the pH of the solution ...

Embodiment 2

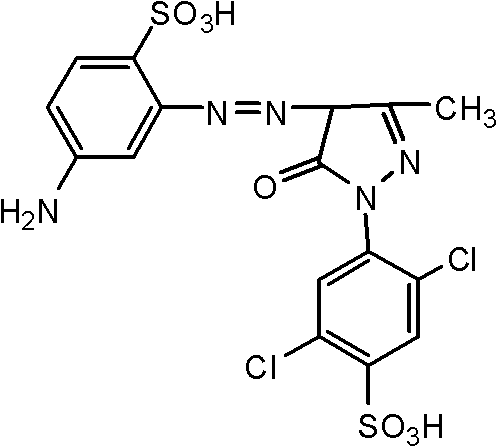

[0054] The preparation of embodiment 2 dyes (2)

[0055]

[0056] The coupling component is selected as 1-(3-aminophenyl)-3-carboxy-5-pyrazolone to replace 1-(4-sulfonic acid phenyl)-3-carboxy-5-pyridine in Example 1 The preparation method of oxazolinone is the same as in Example 1 to obtain yellow dye (2).

Embodiment 3

[0057] The preparation of embodiment 3 dyes (3)

[0058]

[0059] The coupling component is selected as 1-(3-amino-2-methyl-5-sulfonic acid phenyl)-3-methyl-5-pyrazolone to replace 1-(4-sulfonic acid in Example 1 phenyl)-3-carboxy-5-pyrazolone, the preparation method is the same as in Example 1 to obtain a yellow dye (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com