Method for lost foam casting of bimetal bi-solution composite crusher hammer head

A technology of lost foam casting and compound crusher, which is applied in casting molding equipment, metal processing equipment, casting molds, etc. It can solve the problems of unstable composite quality and the inability to realize a group of multiple pieces, so as to save precious metal materials and improve the use of The effect of life and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

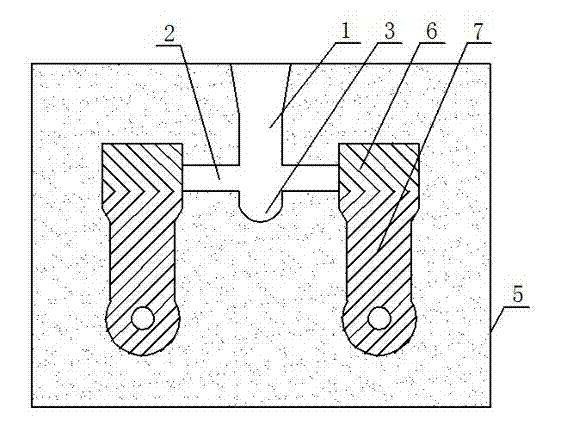

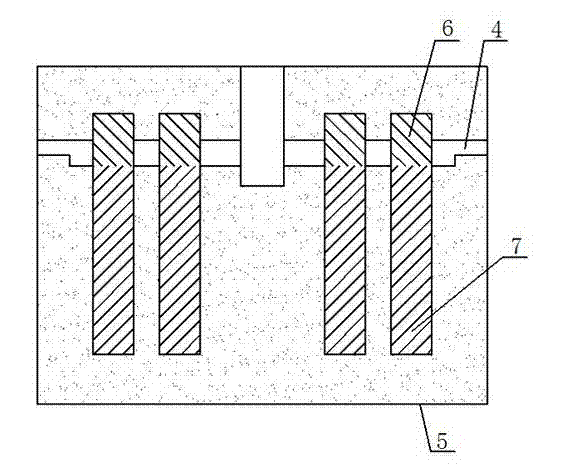

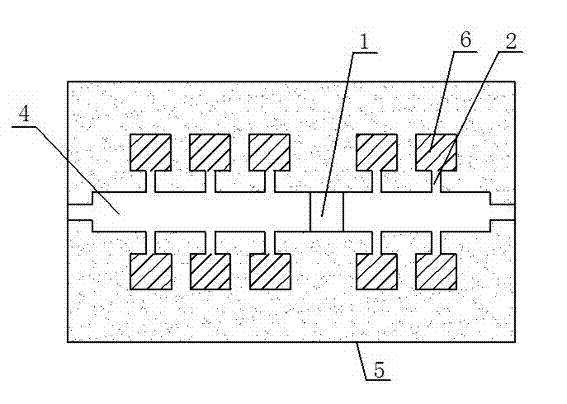

[0018] Below in conjunction with accompanying drawing, the method for the double-metal double-solution composite breaker hammer head of the present invention is further described with lost foam casting:

[0019] The method for casting bimetallic double-solution composite breaker hammer with lost foam, its steps are as follows:

[0020] (—) Set the hammer handle downwards and the working surface upwards in the module composed of patterns; the pattern composition module is formed by connecting the main runner 1, the inner runner 2, the overflow groove 3 and the runner 4 ;The overflow groove 3 is the material 7 of the hammer handle, the upper surface of the gate is the pouring dividing line of the material 7 of the hammer handle, and the upper part is the straight gate of the hammer head material 6 and the main runner 1;

[0021] (2) Melting: At the same time, the above-mentioned hammer head material 6 and hammer handle material 7 are melted separately in two furnaces, hammer hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com