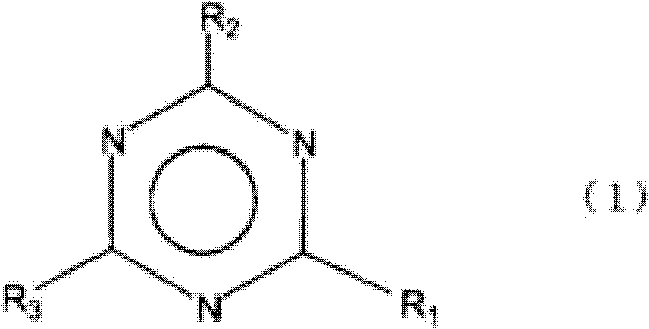

Polycarbonate resin composition and molded article formed of same

A technology of polycarbonate resin and resin composition, which is applied in the field of polycarbonate resin composition and molded articles made of the same, and can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

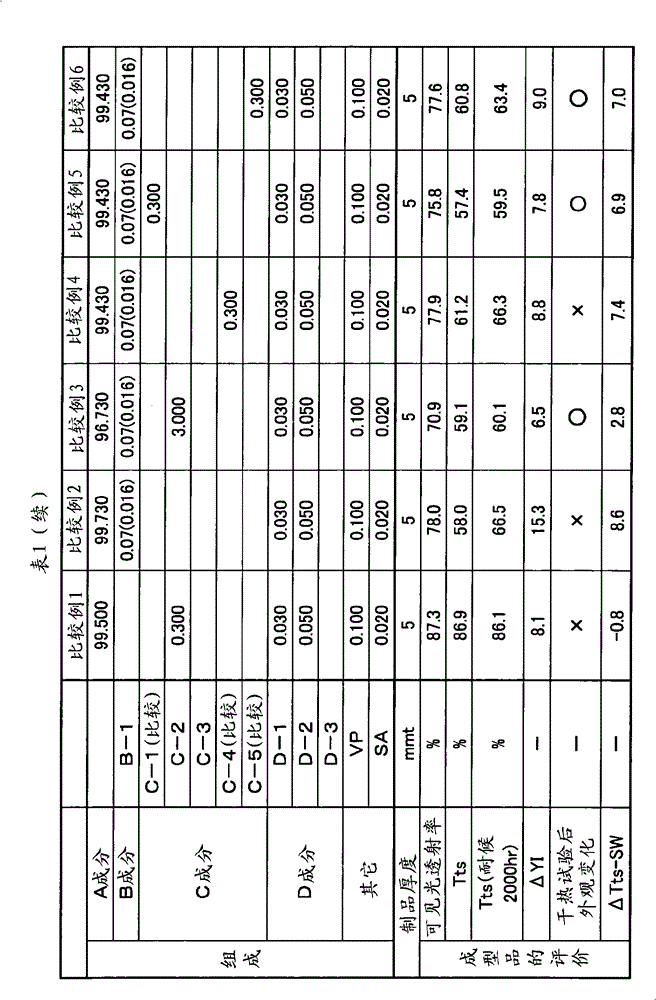

Examples

Embodiment 1~9 and comparative example 1~6

[0099] (1) Raw materials used

[0100] (A component)

[0101] PC: Polycarbonate resin powder with a molecular weight of 24,200 obtained by the following manufacturing method

[0102] A three-section six-blade stirrer and a reflux cooling pipe are installed on the reaction vessel with a baffle. 45.6 parts of bisphenol A, 2.78 mol % of p-tert-butylphenol relative to bisphenol A, 265 parts of dichloromethane, and 200 parts of water were added to the reaction container, and nitrogen purging was performed to remove oxygen in the reaction container. . In addition, in this step, the content of the reaction vessel was less than 80% of the capacity of the vessel. Next, about 80 parts of an aqueous solution for supplying 0.09 parts of sodium dithionite and 21.8 parts of sodium hydroxide was supplied to the suspension, and bisphenol A was dissolved at 15°C. 23.35 parts of phosgene were supplied to this mixture over 30 minutes with stirring. Then, 0.016 parts of triethylamine (0.08 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com