Novel semiconductor lead processing device

A processing device and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as low production efficiency, burrs in the incision, unstable product length, etc., and achieve high production efficiency, no burrs, and products The effect of length stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

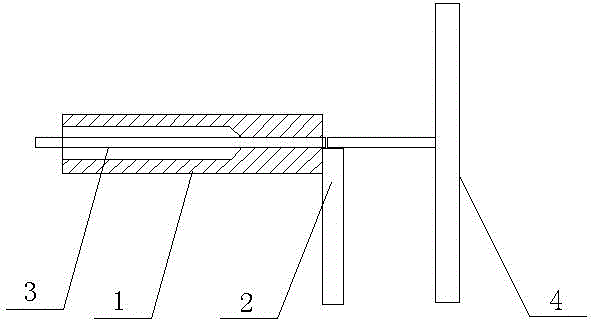

[0009] refer to figure 1 , the specific embodiment adopts the following technical scheme: it includes a threading block 1, a cutter 2, a threading hole 3 and a positioning device 4, a threading hole 3 is arranged in the threading block 1, and the cutter 2 is vertically fixed on the outlet side of the threading hole 3 , The side of the cutter 2 is provided with a positioning device 4 .

[0010] The cutter 2 is closely attached to the outlet of the threading hole 3 .

[0011] When this specific embodiment is used, the wire is passed through the threading hole 3 in the threading block 1 , and when one end of the wire reaches the positioning device 4 , the wire is cut off by the cutter 2 .

[0012] The specific implementation mode can make the product length stable, the incision is flush, no burrs, and the production efficiency is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com