Heating control method for nitrogen oxygen sensor

A technology of nitrogen and oxygen sensor and heating control, which is applied in the field of nitrogen and oxygen sensors, can solve the problems of nitrogen and oxygen sensor measurement errors, affecting the ability of measuring electrodes to catalytically decompose NOx, measuring pump current measurement errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

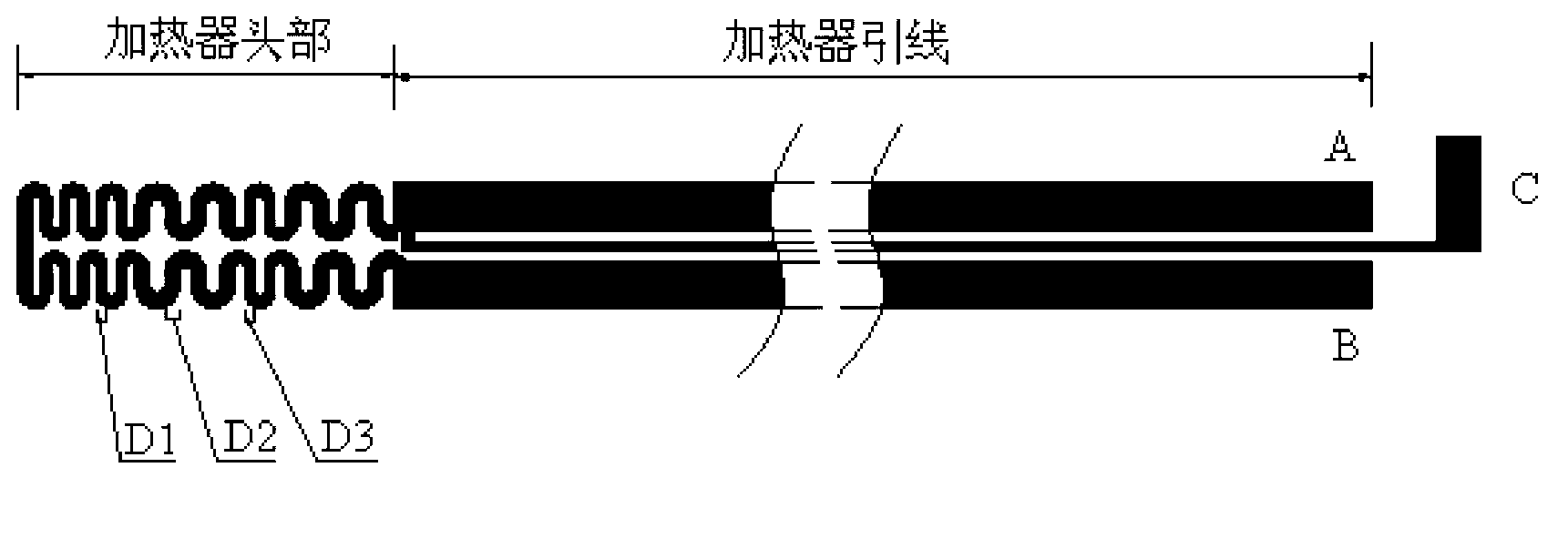

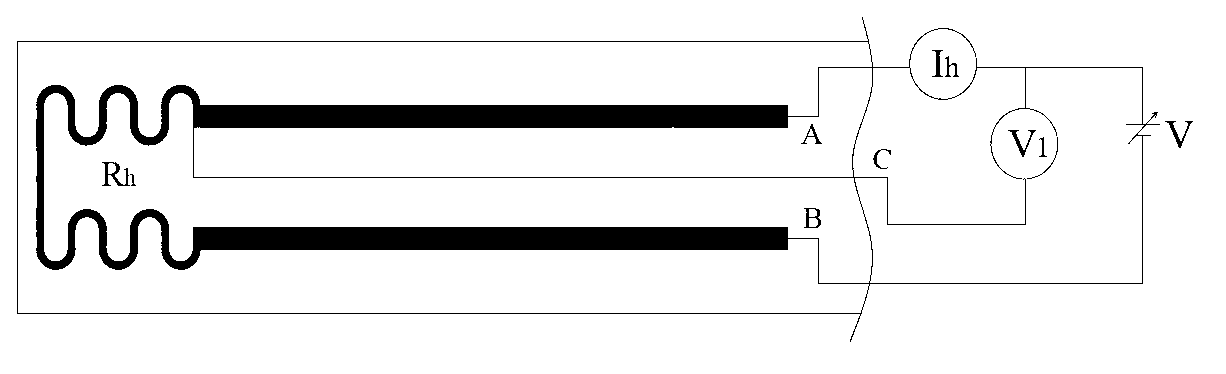

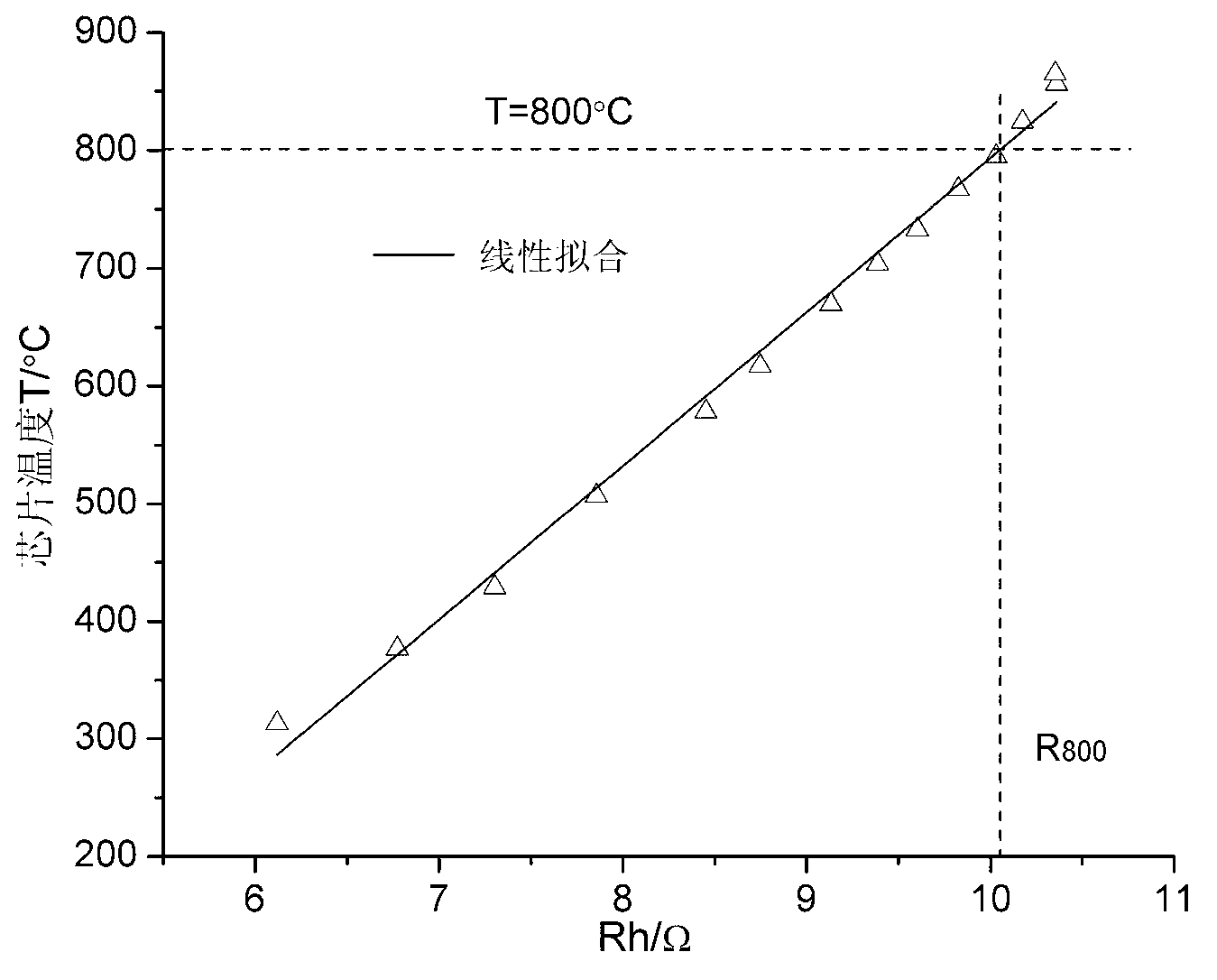

[0031] A nitrogen and oxygen sensor heating control method, the nitrogen and oxygen sensor includes a signal function layer and a heater located below the signal function layer, the heater includes a heater head and lead wires A and lead wires respectively connected to both ends of the heater head B. A measuring electrode C for collecting the resistance value of the heater head is arranged between the voltage application end A and the B end of the heater. One end of the measuring electrode C is connected between the heater head and the lead wire A or lead wire B. Junction. In this method, the resistance value of the heater head is used to characterize the temperature value change of the nitrogen and oxygen sensor chip head, and the operating temperature value of the nitrogen and oxygen sensor chip is controlled at 800 by changing the volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com