A differential deep water blowout preventer control valve

A blowout preventer control, differential technology, applied in wellbore/well valve device, wellbore/well components, earth-moving drilling and other directions, can solve the problems of inability to meet offshore development, equipment dependent on wellhead, slow development, etc. , to achieve the effect of easy modular installation, compact structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

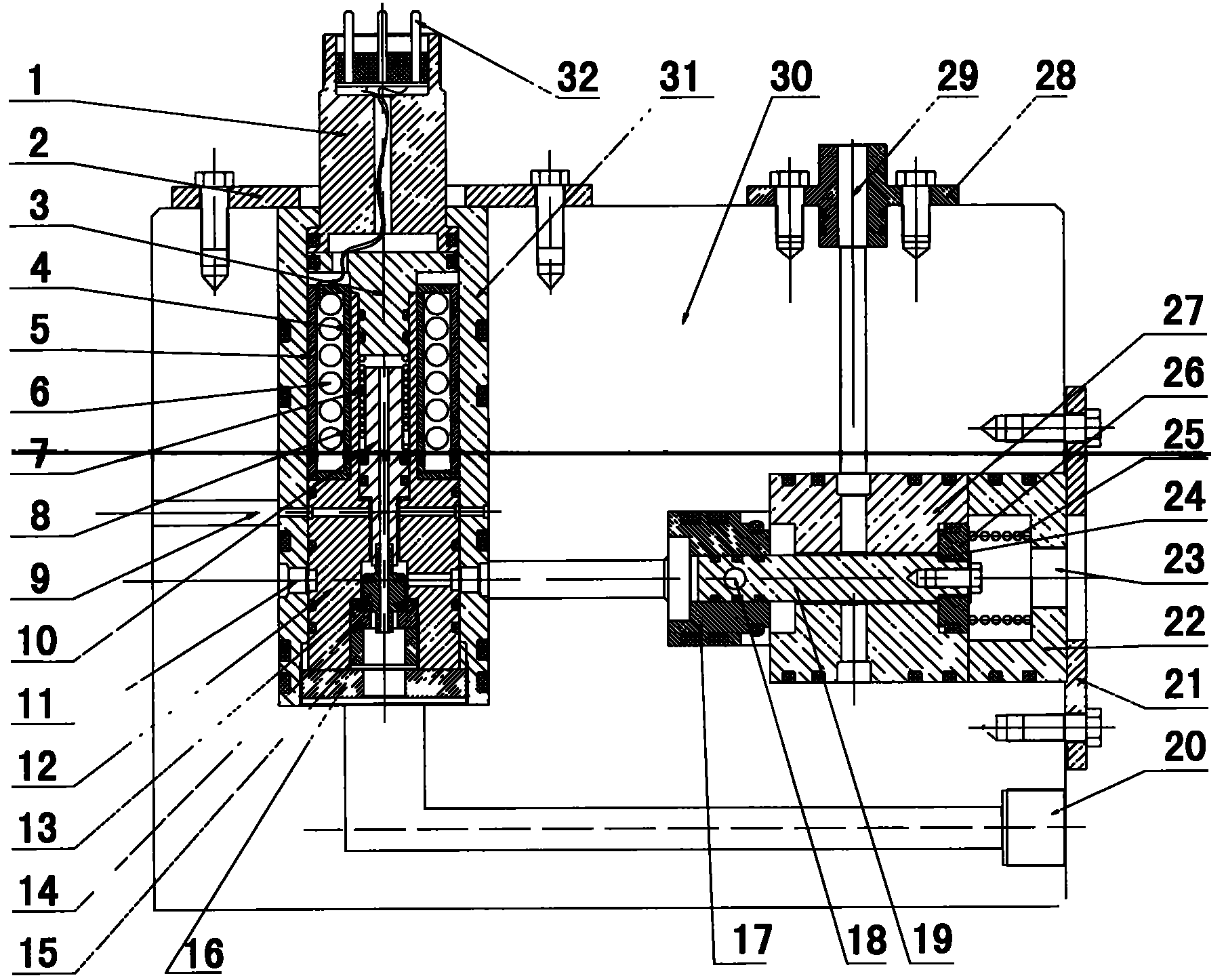

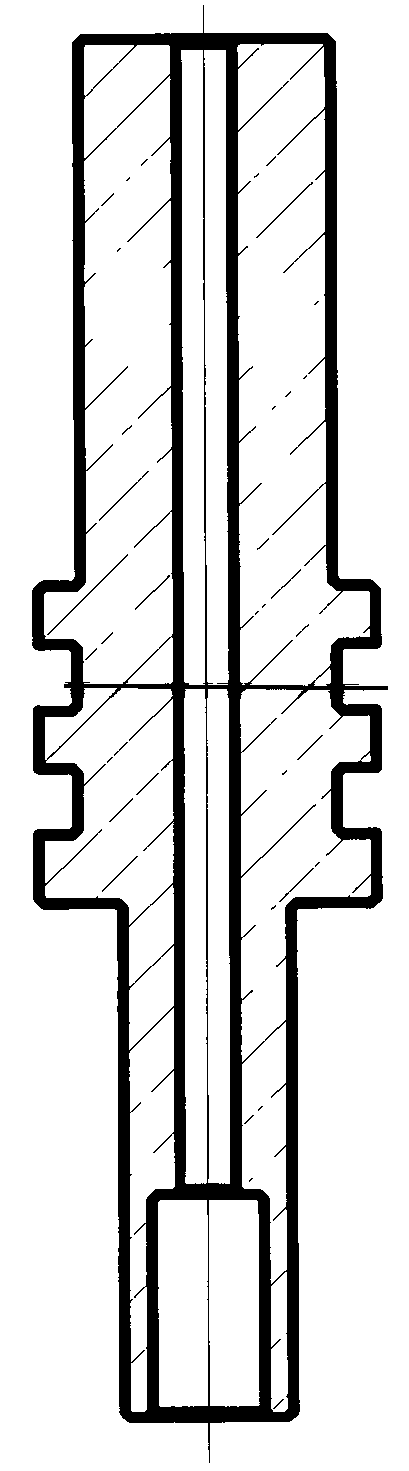

[0015] see figure 1 , figure 2 . The control valve of the differential deep water blowout preventer of the present invention is mainly composed of a cable plug 1, a gland 2, an upper valve seat 3, an electromagnetic coil seat 4, a magnetic conducting ring 5, an electromagnetic coil 6, a sealing ring 7, a compression spring 8, and a discharge valve. Port 9, iron core 10, pilot valve oil supply port 11, solenoid valve spool seat 12, spool 13, solenoid control valve lower seat 14, back tightening nut 15, back tightening nut 16, pilot valve front spool 17, Drain oil port 18, pilot valve push rod 19, electromagnetic control valve oil supply port 20, gland 21, pilot valve rear valve seat 22, high pressure and large flow oil supply port 23, radial sealing ring 24, compression spring 25, pilot valve Rear spool 26, pilot valve seat 27, connector 28, blowout preventer oil supply port 29, valve body 30, electromagnetic control valve valve body 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com