Open-joint and dry-hanging aluminum plate curtain wall connecting structure with glass rib

A technology of connecting structure and glass rib, applied in the direction of wall, building component, building structure, etc., can solve the problem of not being able to realize the structure of glass rib on dry-hanging aluminum panel curtain wall, and achieve pollution-free assembly, easy disassembly and replacement. , the effect of beautiful assembly and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

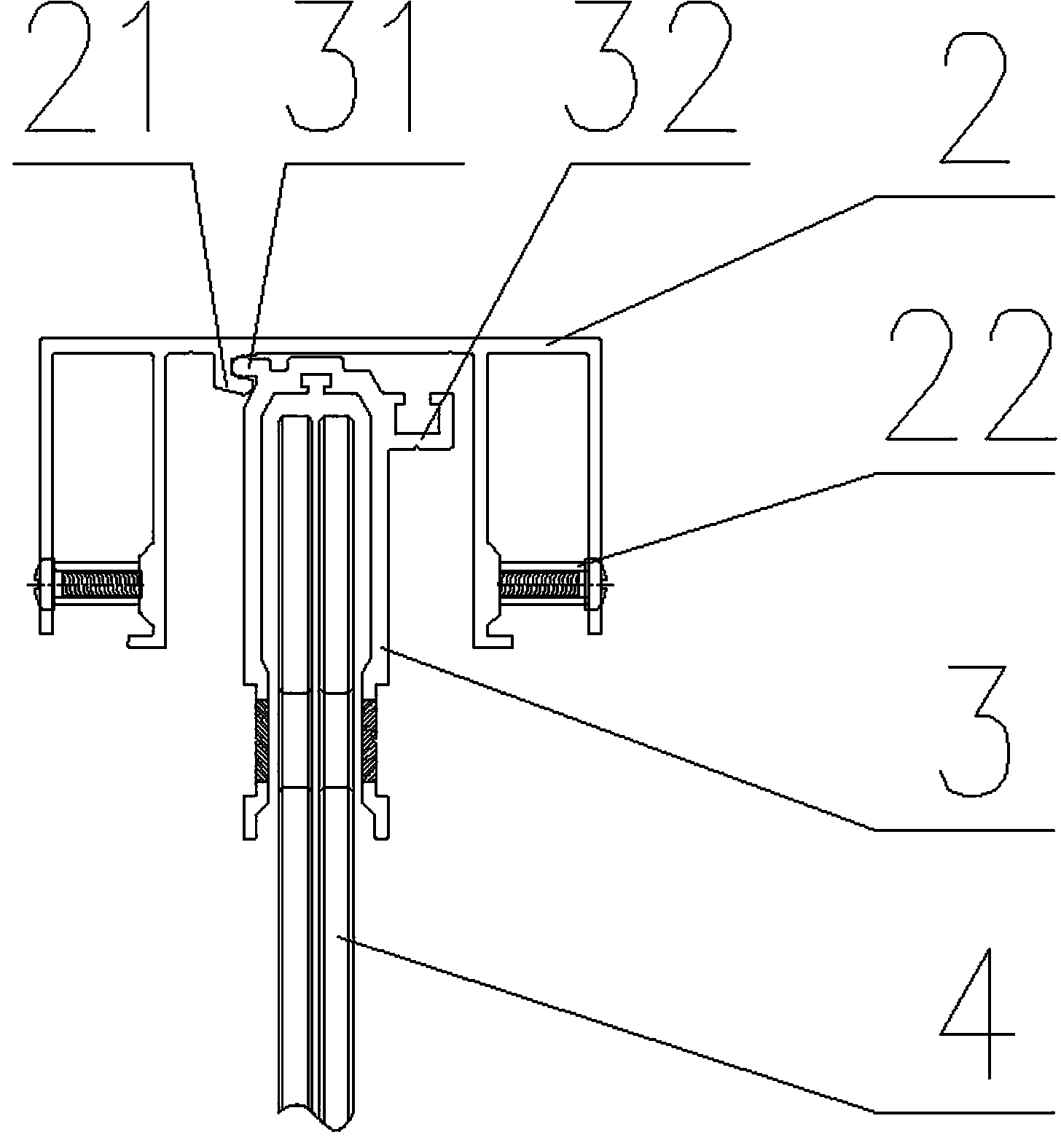

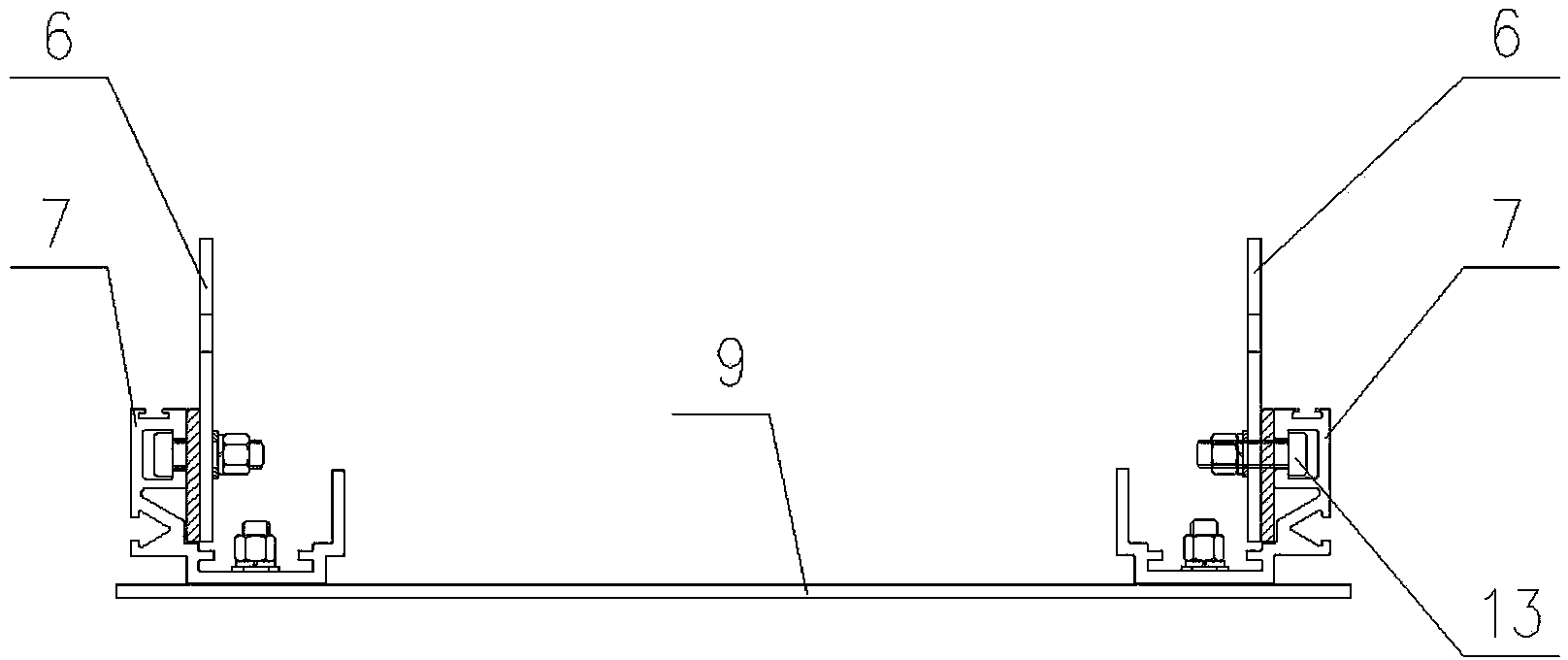

[0012] Open-slit dry-hanging aluminum curtain wall connection structure with glass ribs, each node is specifically fixed in the middle of two adjacent facing aluminum plates 9 with a glass rib 4 perpendicular to the facing aluminum plate 9, and its fixing structure includes a The internal main body steel structure is connected with a fixed square steel pipe 1, and the outer side of the square steel pipe 1 is fixed with an aluminum profile keel 2 by a number of screws. The aluminum profile keel 2 includes a central main cavity and auxiliary cavities on both sides. The positioning card slot 21, the auxiliary cavity is horizontally fixed with a support screw 22, the main cavity of the aluminum profile keel 2 is fixed with an aluminum alloy glass rib card slot 3, and the left end of the outer end surface of the aluminum alloy glass rib card slot 3 is provided with a positioning card slot 21 The matching lug 31, the right end of the outer end surface of the aluminum alloy glass rib ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com