Method for extracting essential oil from orange peel

A technology of orange peel and essential oil, applied in the directions of essential oil/spice, fat production, etc., can solve the problems of insufficient aroma, low oil yield, complicated process, etc., and achieve the effect of improving oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for extracting essential oil from orange peel, comprising the following steps:

[0017] 1 Select fresh orange peels without mildew, and put them in a cool, ventilated and dry place for later use;

[0018] 2 Take 100 g of orange peels from step 1) and soak them in 1 L of calcium carbonate saturated aqueous solution for 24 hours, remove and rinse;

[0019] 3. Cut the orange peel into 5mm square pieces, soak in ethanol with a volume fraction of 70% for 30 minutes, and remove the ethanol by rotary evaporation under reduced pressure;

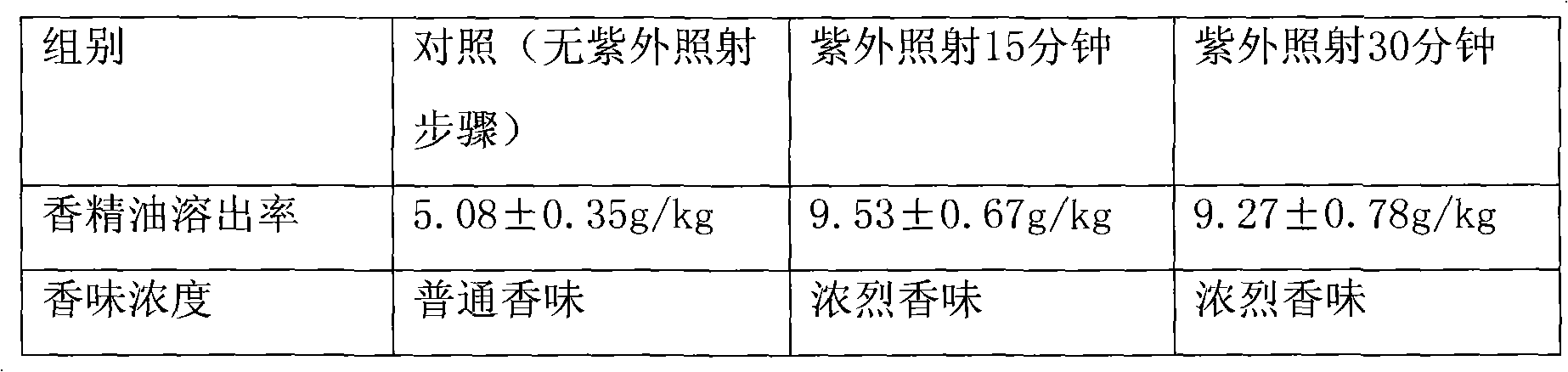

[0020] 4 Irradiate under ultraviolet light for 15 minutes, send it into a screw press, add 100ml of pH regulator when pressing, the components of pH regulator are: 0.2mol / L NaCl and 0.1mol / L NaHCO 3 ;

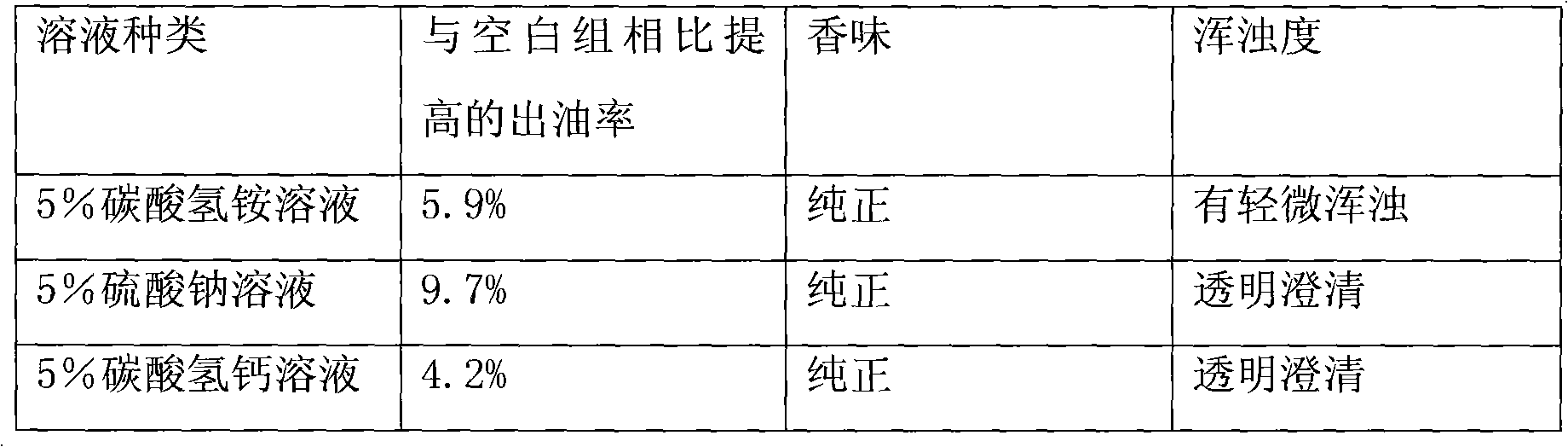

[0021] 5. Get the filtrate after filtering the squeezed matter, and take out the filter residue for the subsequent production process of other products; add a mass volume fraction of 5% sodium sulfate solution at a volume ratio of 10...

Embodiment 2

[0023] A method for extracting essential oil from orange peel, comprising the following steps:

[0024] 1 Select fresh orange peels without mildew, and put them in a cool, ventilated and dry place for later use;

[0025] 2 Take 100 g of orange peels from step 1) and soak them in 1 L of calcium carbonate saturated aqueous solution for 24 hours, remove and rinse;

[0026] 3 Cut the orange peel into 5mm square pieces, soak in 70% ethanol for 40 minutes, and remove the ethanol by rotary evaporation under reduced pressure;

[0027] 4 Irradiate under ultraviolet light for 30 minutes, send it into the screw press, add 100ml of pH regulator when pressing, the components of the pH regulator are: 0.2mol / L NaCl and 0.1mol / L NaHCO 3 ;

[0028] 5. Get the filtrate after filtering the squeezed matter, and take out the filter residue for the subsequent production process of other products; add a mass volume fraction of 5% sodium sulfate solution at a volume ratio of 10:1 according to the f...

Embodiment 3

[0030] 1, by the essential oil component analysis that embodiment 1 extracts:

[0031] The components of essential oils were analyzed by GC-MS technology: D-limonene 81.17%, terpinene 6.27%, myrcene 2.96%, linalool 2.468%, 2-thujene 1.28%, terpinolene 1.046%, and other minor components.

[0032] The beneficial effect that extraction process of the present invention brings:

[0033] 2. Appropriate amount of ethanol treatment:

[0034] Using an appropriate amount of ethanol treatment greatly releases the dissolution rate of the essential oil, and the ethanol treatment step avoids being mixed into the essential oil before the pressing step; the influence of the ethanol treatment step on the dissolution rate of the essential oil: according to the operation method of Example 1 , repeating ten batches, removing the ethanol treatment step and repeating ten batches; we found that the embodiment of the ethanol treatment step was not adopted, and the productive rate was 7.18 ± 0.23g / k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com