Method for catalytically oxidizing quinclorac

A kind of quinclorac, catalytic oxidation technology, applied in the direction of organic chemistry and the like, can solve the problems of long oxidation time, poor product quality, low yield and the like, and achieve the effects of short oxidation time, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

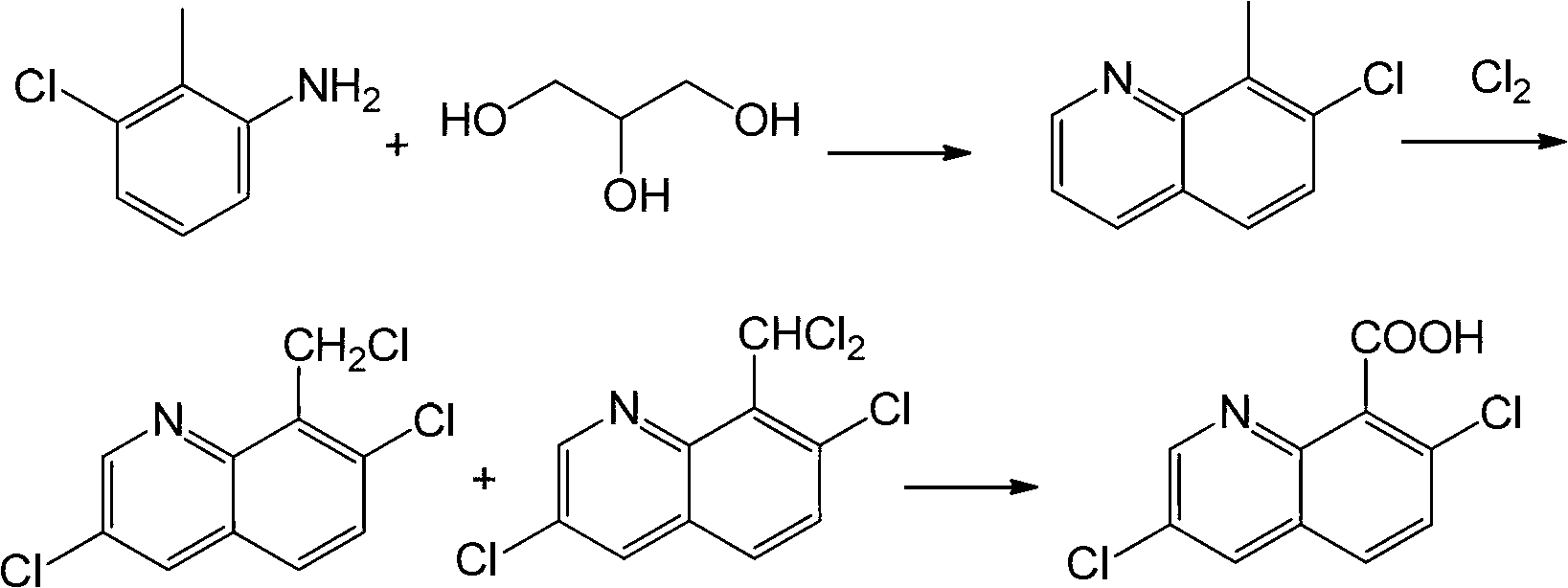

Image

Examples

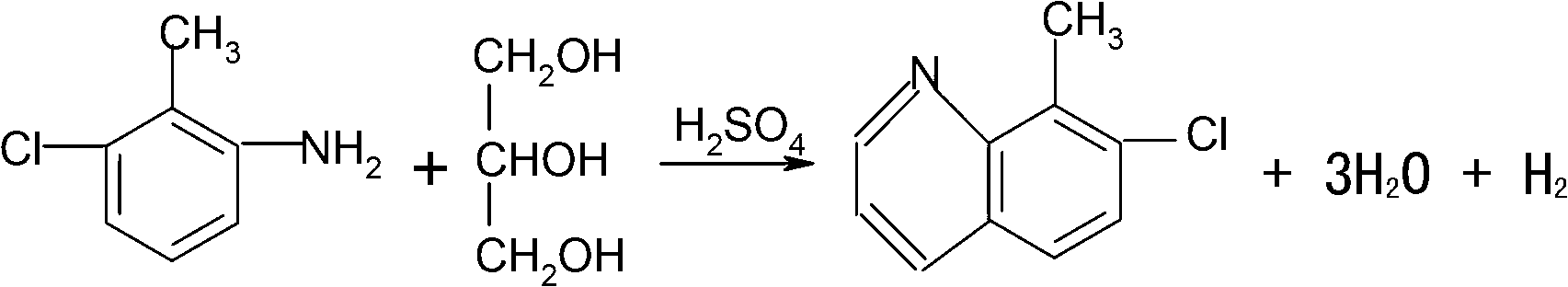

Embodiment 1

[0030] First add 125mL of water to the reaction bottle A, and add 560g of concentrated sulfuric acid (98%) dropwise under stirring. After the dropwise addition, start to add 250g of 3-chloro-2-methylaniline, 2g of potassium iodide, and start to add 185g of glycerol dropwise. Generally, the dropwise addition ends in 3 hours, and the dropping temperature is kept at 148-150°C. Keep warm for 2.5 hours, add 400mL of water at the end of the heat preservation, cool down to below 40°C, add 1000ml of petroleum ether (boiling range of 60-90°C). Start adding dilute lye (32%) dropwise. When the pH reaches 9-10, stop the dropwise addition, and separate the layers after standing for half an hour. The upper material is filtered, the filter cake is washed with 200ml of petroleum ether, the filtrates are combined, and distilled at atmospheric pressure until no fraction comes out. After the distillation was finished, 1000 ml of o-dichlorobenzene was added for use in the next step of chlorinati...

Embodiment 2

[0034] First add 125mL of water to the reaction bottle A, and add 560g of concentrated sulfuric acid (98%) dropwise under stirring. After the dropwise addition, start to add 250g of 3-chloro-2-methylaniline, 2g of potassium iodide, and start to add 185g of glycerol dropwise. Generally, the dropwise addition ends in 3 hours, and the dropping temperature is kept at 148-150°C. Keep warm for 2.5 hours, add 400mL of water at the end of the heat preservation, cool down to below 40°C, add 1000ml of petroleum ether (boiling range of 60-90°C). Start adding dilute lye (32%) dropwise. When the pH reaches 9-10, stop the dropwise addition, and separate the layers after standing for half an hour. The upper material is filtered, the filter cake is washed with 200ml of petroleum ether, the filtrates are combined, and distilled at atmospheric pressure until no fraction comes out. After the distillation was finished, 1000 ml of o-dichlorobenzene was added for use in the next step of chlorinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com