Mechanochemical preparation method and equipment of magnetic water treatment agent

A technology of mechanochemistry and treatment agent, applied in chemical instruments and methods, biological water/sewage treatment, adsorbed water/sewage treatment, etc. The effect of condensation adsorption, good magnetic responsiveness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

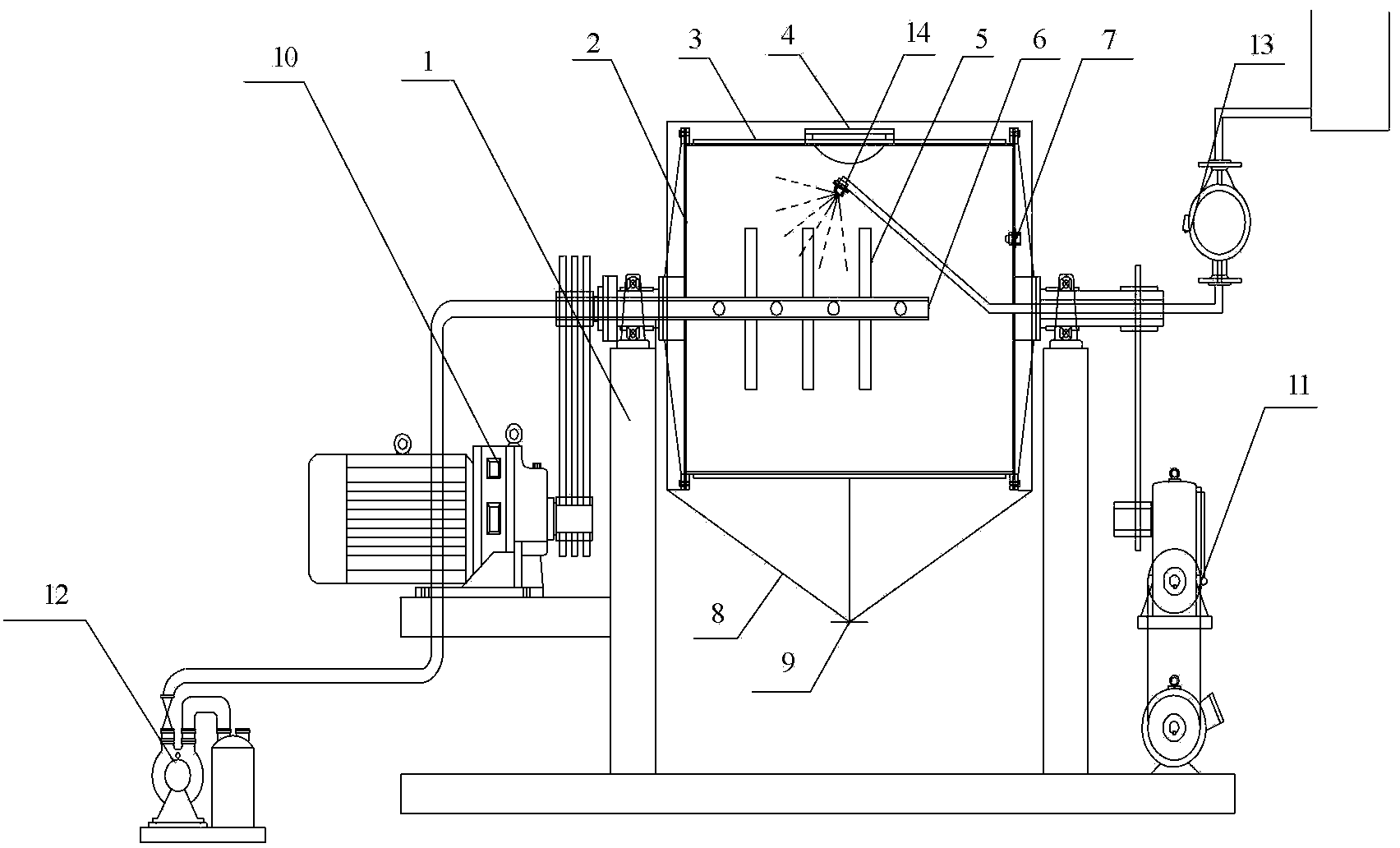

Method used

Image

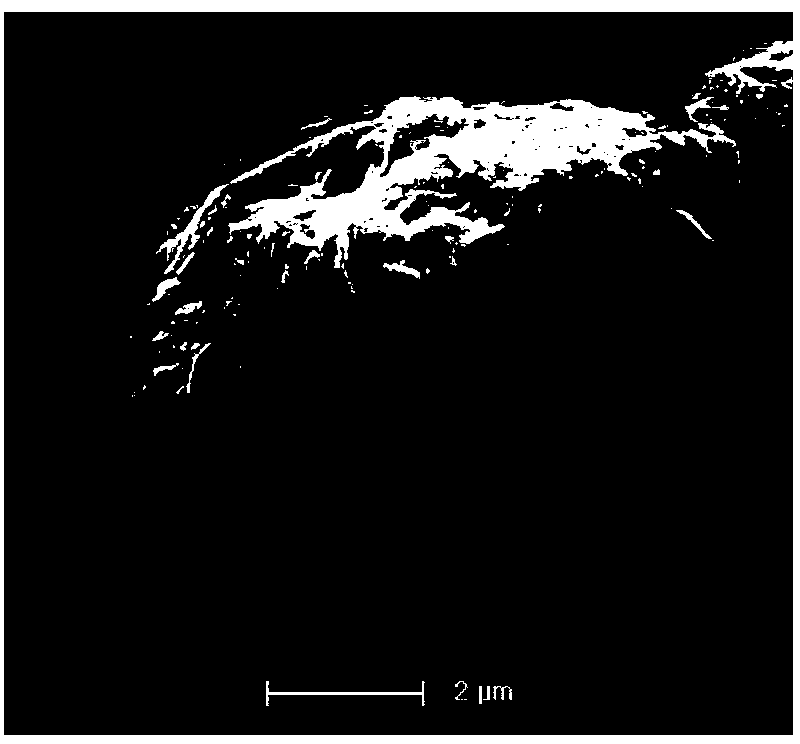

Examples

Embodiment 1

[0041] First, add 120 kg of magnetite powder into a cylinder with a volume of 500L. Among them, the moisture content of magnetite powder is less than 3%, the particle size is 200-325 mesh, accounting for more than 85%, and the iron content is 65%. Then add glass 300 kilograms of balls, the gradation of glass balls is: Φ18mm accounts for 20% of the total weight of the ball milling medium, Φ12mm accounts for 35% of the total weight of the ball milling medium, and Φ10mm accounts for 45% of the total weight of the ball milling medium. After covering the cover plate, start the variable frequency speed regulating motor that drives the cylinder to rotate. The cylinder rotates at a speed of 25 rpm. While rolling and milling the material, slowly start the frequency conversion speed regulating motor that drives the internal rotation stirring device for mixing and ball milling. , the rotational speed of the internally rotating stirring shaft is 70 rpm. Circulate hot water into the jacket...

Embodiment 2

[0043] First, add 90 kg of iron oxide scale to the 500L volume horizontal double-rotor mixing equipment. Among them, the water content of the oxide scale is less than 2%, the particle size is 200-450 mesh, accounting for more than 85%, and the iron grade is 71.5%. Then add agate balls 250 kg, the gradation of agate balls is: Φ14mm accounts for 25% of the total weight of the ball milling medium, Φ12mm accounts for 45% of the total weight of the ball milling medium, and Φ8mm accounts for 30% of the total weight of the ball milling medium. After covering the cover plate, start the frequency conversion speed regulation motor that drives the cylinder to rotate. The rotation speed of the cylinder is 40 rpm. While the material is rolling and ball milling, slowly start the frequency conversion speed regulation motor that drives the internal rotation stirring device for mixing and ball milling. , the rotational speed of the internally rotating stirring shaft is 70 rpm.

[0044] Circula...

Embodiment 3

[0046] First, add 100 kg of iron oxide scale to the 500L volume horizontal double-rotating mixing equipment, in which the water content of the iron oxide scale is less than 1%, the particle size is 200-450 mesh, accounting for more than 80%, and the iron content is 72%. Then add zircon The ball is 280 kg, and the gradation of zircon balls is: Φ16mm accounts for 20% of the total weight of the ball milling medium, Φ12mm accounts for 40% of the total weight of the ball milling medium, and Φ8mm accounts for 40% of the total weight of the ball milling medium. After covering the cover plate, start the frequency conversion speed regulating motor that drives the cylinder to rotate. The cylinder rotates at a speed of 30 rpm. While rolling and milling the material, slowly start the frequency conversion speed regulation motor that drives the internal rotation stirring device for mixing and ball milling. , the rotational speed of the internally rotating stirring shaft is 60 rpm.

[0047] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com