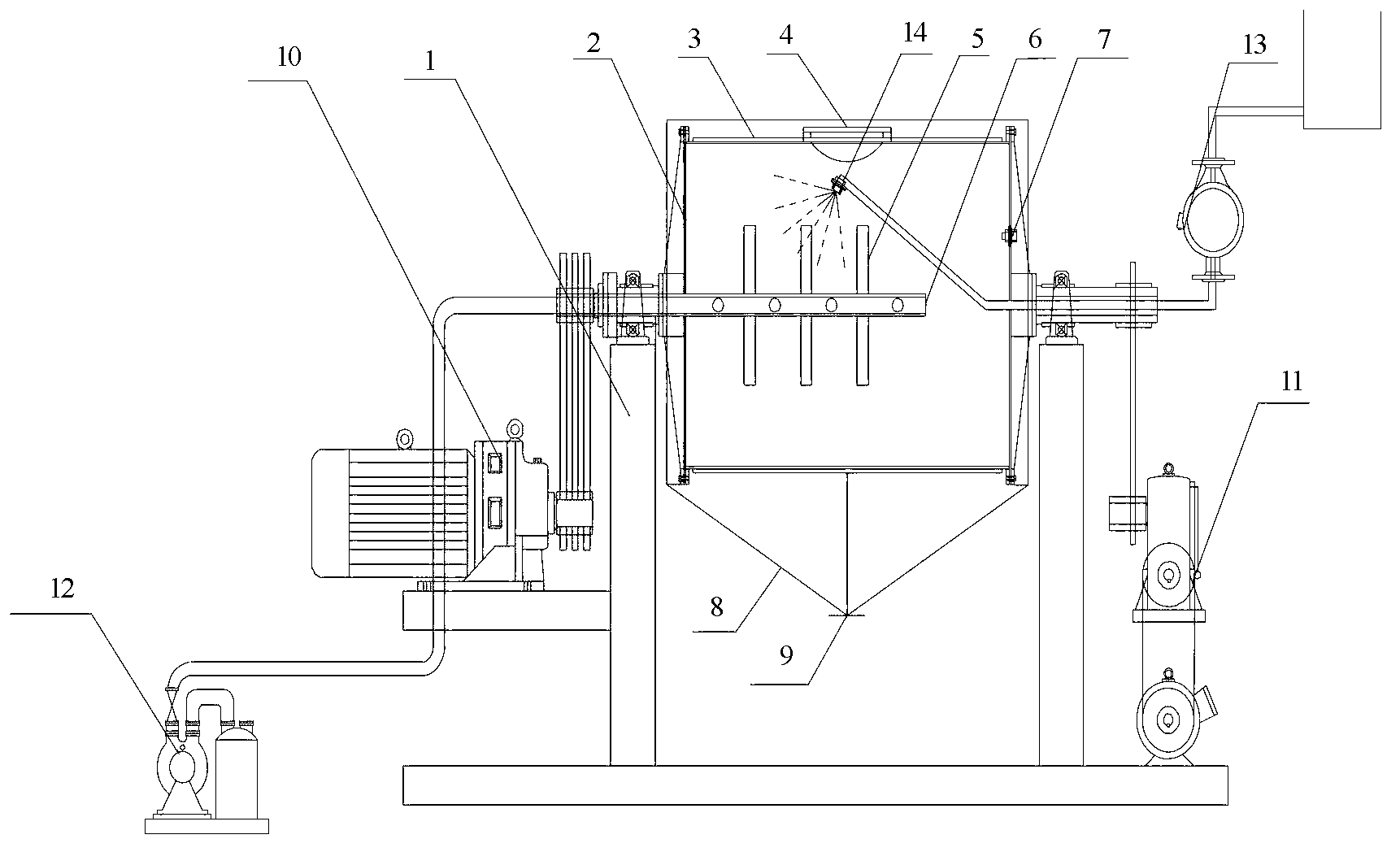

Mechanochemical preparation method and equipment of magnetic water treatment agent

A mechanochemical and treatment agent technology, applied in chemical instruments and methods, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of water yellowing, complex finished products, high energy consumption, etc., and achieve good mixing The effects of condensation adsorption, good magnetic response, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

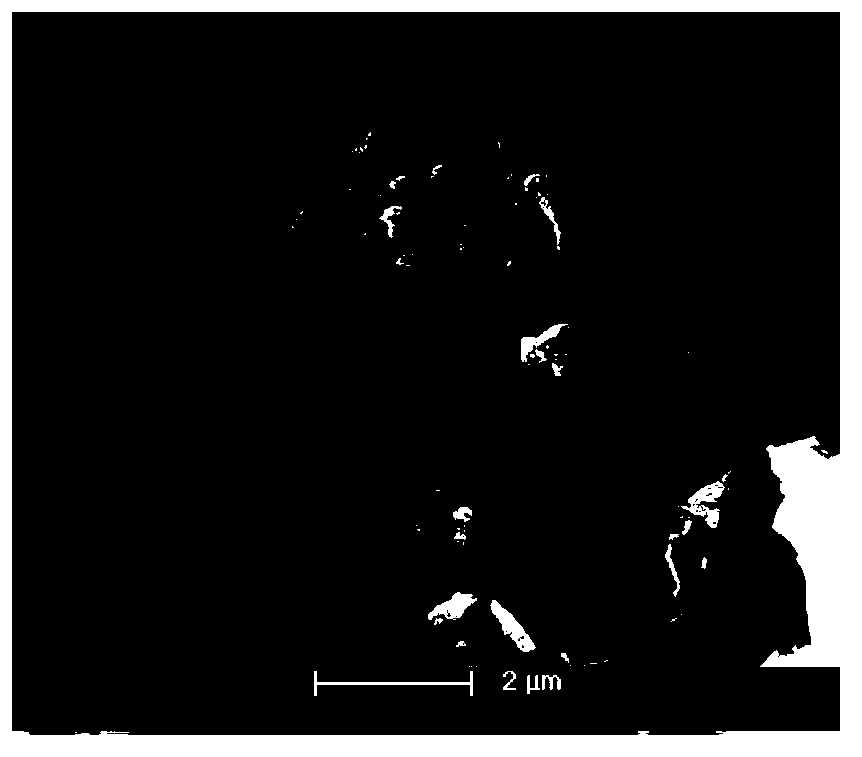

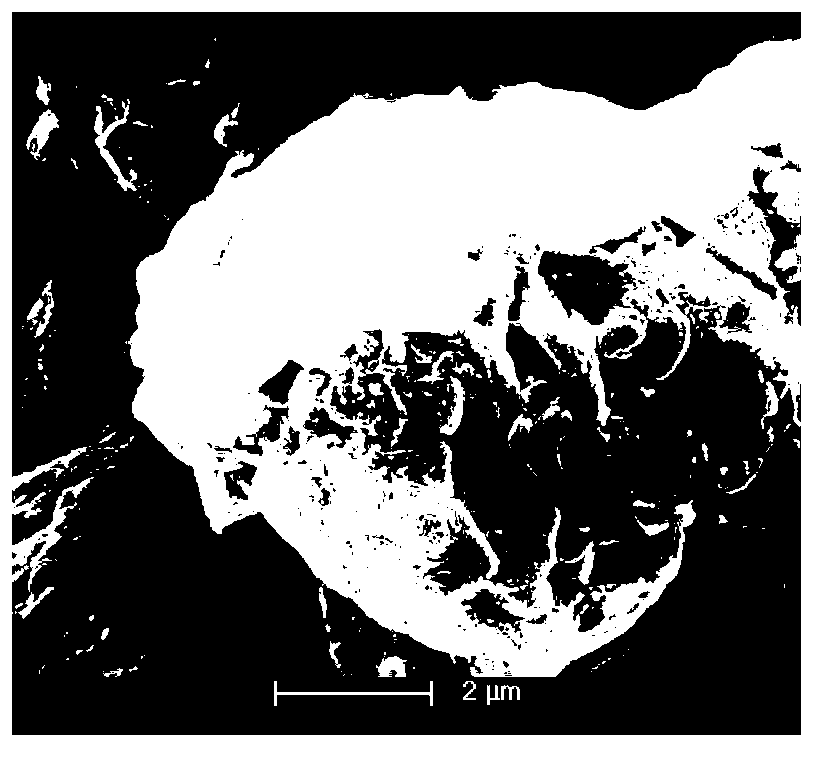

Examples

Embodiment 1

[0041] First, add 120 kg of magnetite powder to the 500L volume cylinder, wherein the magnetite powder has a moisture content of less than 3%, a particle size of 200-325 mesh, more than 85%, and an iron content of 65%. Then add glass The ball is 300 kg, and the glass ball gradation is as follows: Φ18mm accounts for 20% of the total weight of the ball milling medium, Φ12mm accounts for 35% of the total weight of the ball milling medium, and Φ10mm accounts for 45% of the total weight of the ball milling medium. After covering the cover plate, start the variable frequency speed regulating motor that drives the cylinder to rotate. The rotation speed of the cylinder is 25 rpm. While rolling the material, slowly start the variable frequency speed regulating motor that drives the internal rotation stirring device to perform stirring and mixing ball milling. , the rotational speed of the inner rotating stirring shaft is 70 rev / min. Circulate hot water into the jacket of the cylinder, ...

Embodiment 2

[0043] First, add 90 kg of iron oxide scale to the 500L volume horizontal double-rotation mixing equipment. The moisture content of the iron oxide scale is less than 2%, the particle size is 200-450 mesh, accounting for more than 85%, and the iron content is 71.5%. Then add agate balls. 250 kg, the agate ball gradation is: Φ14mm accounts for 25% of the total weight of the ball milling media, Φ12mm accounts for 45% of the total weight of the ball milling media, Φ8mm accounts for 30% of the total weight of the ball milling media. After covering the cover, start the variable frequency speed regulating motor that drives the cylinder to rotate. The rotation speed of the cylinder is 40 r / min. While rolling the material, slowly start the variable frequency speed regulating motor that drives the internal rotation stirring device for stirring and mixing ball milling. , the rotational speed of the inner rotating stirring shaft is 70 rev / min.

[0044] Circulate hot water into the jacket ...

Embodiment 3

[0046] First, add 100 kg of iron oxide scale to the 500L volume horizontal double-rotation mixing equipment. The moisture content of the iron oxide scale is less than 1%, the particle size is 200-450 mesh, accounting for more than 80%, and the iron content is 72%. Then add zircon. The ball is 280 kg, and the zircon ball gradation is: Φ16mm accounts for 20% of the total weight of the ball milling medium, Φ12mm accounts for 40% of the total weight of the ball milling medium, and Φ8mm accounts for 40% of the total weight of the ball milling medium. After covering the cover plate, start the variable frequency speed regulating motor that drives the cylinder to rotate. The rotating speed of the cylinder is 30 rpm. While rolling the material, slowly start the variable frequency speed regulating motor that drives the internal rotation stirring device to perform stirring and mixing ball milling. , the rotational speed of the inner rotating stirring shaft is 60 rev / min.

[0047] Circula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com