Treatment method of organic wastewater of coal liquefaction

A technology of organic wastewater and treatment methods, applied in the direction of heating water/sewage treatment, etc., can solve the problems of difficult treatment, secondary discharge pollution, waste water and sewage treatment, etc., and achieve the goal of reducing discharge pollution, reducing waste water discharge, and reducing discharge volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

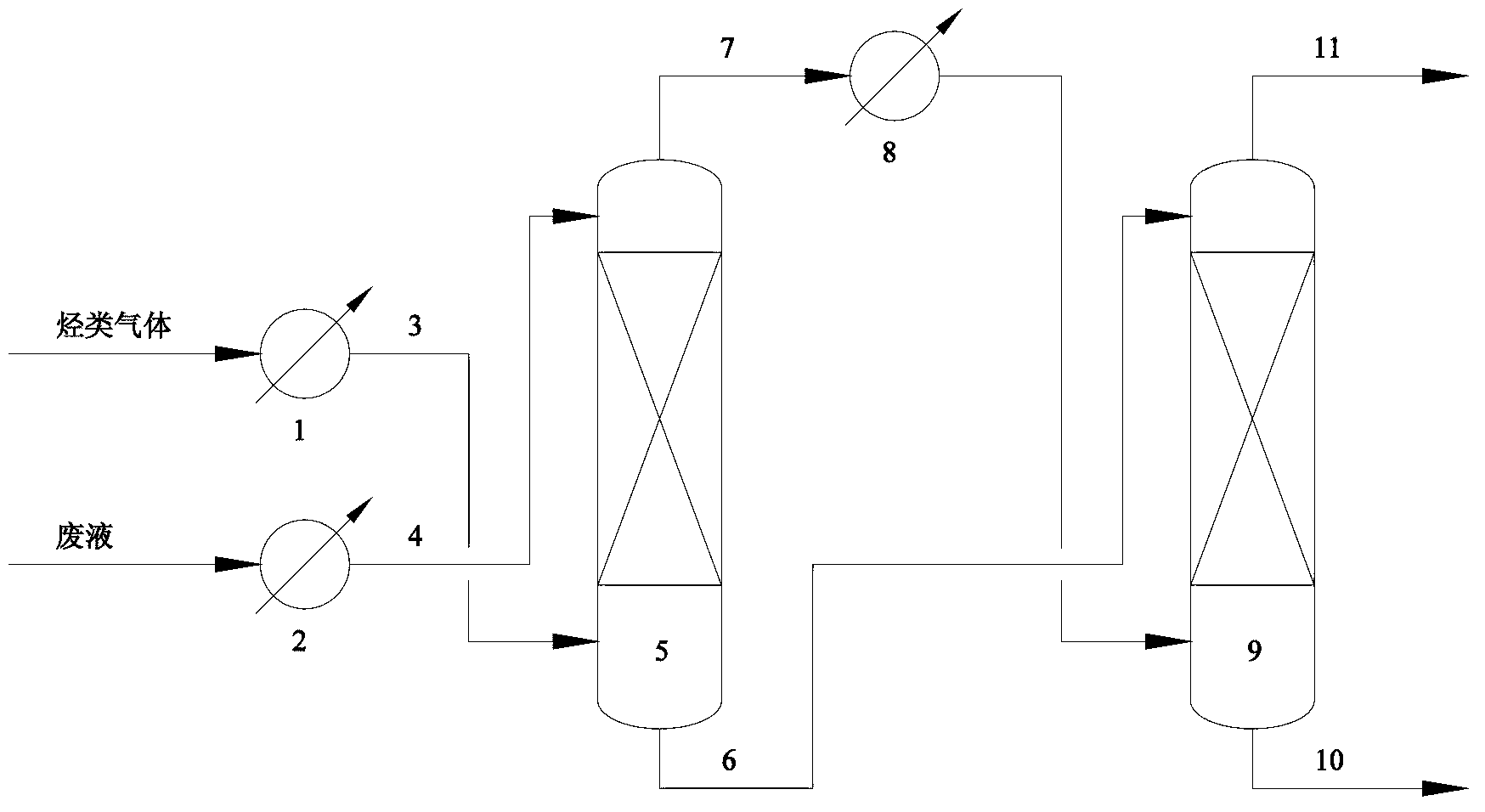

[0037] refer to figure 2 Shown, the hydrocarbon-containing gas, its composition (volume percentage) is CH 4 :26.7%, C 2 h 6 : 1.3%, C 2 h 4 :1.3%, H 2 : 58.4%, CO: 6.4%, CO 2 : 0.1%, N 2 : 4.6%, H 2 O: 1.2%, after being preheated by the preheater 1 to a temperature of 350°C, it is sent to the primary stripper 5 from the lower gas inlet under the condition of a gas flow rate of 7480 kmol / h; it comes from the preparation of synthetic oil by Fischer-Tropsch synthesis The raw water of organic wastewater discharged from the process is preheated to a temperature of 150°C by the preheater 2, and then sent to the primary stripper 5 from the upper liquid inlet at a flow rate of 85t / h.

[0038] In the primary stripping tower 5, the organic waste water is stripped by hydrocarbon gas, and the stripped organic waste water 6 leaves from the bottom of the tower. Leaving from the top of the primary stripping tower, the gas flow is 9881 kmol / h and the temperature is 160.8°C.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com