Brine crystallizing salt-manufacturing apparatus

A water collection device and brine technology, applied in the direction of alkali metal chlorides, energy input, etc., can solve the problems of a large amount of carbon dioxide, waste of energy, air pollution, etc., achieve output and quality improvement, save energy and land resources, and benefit the environment The effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

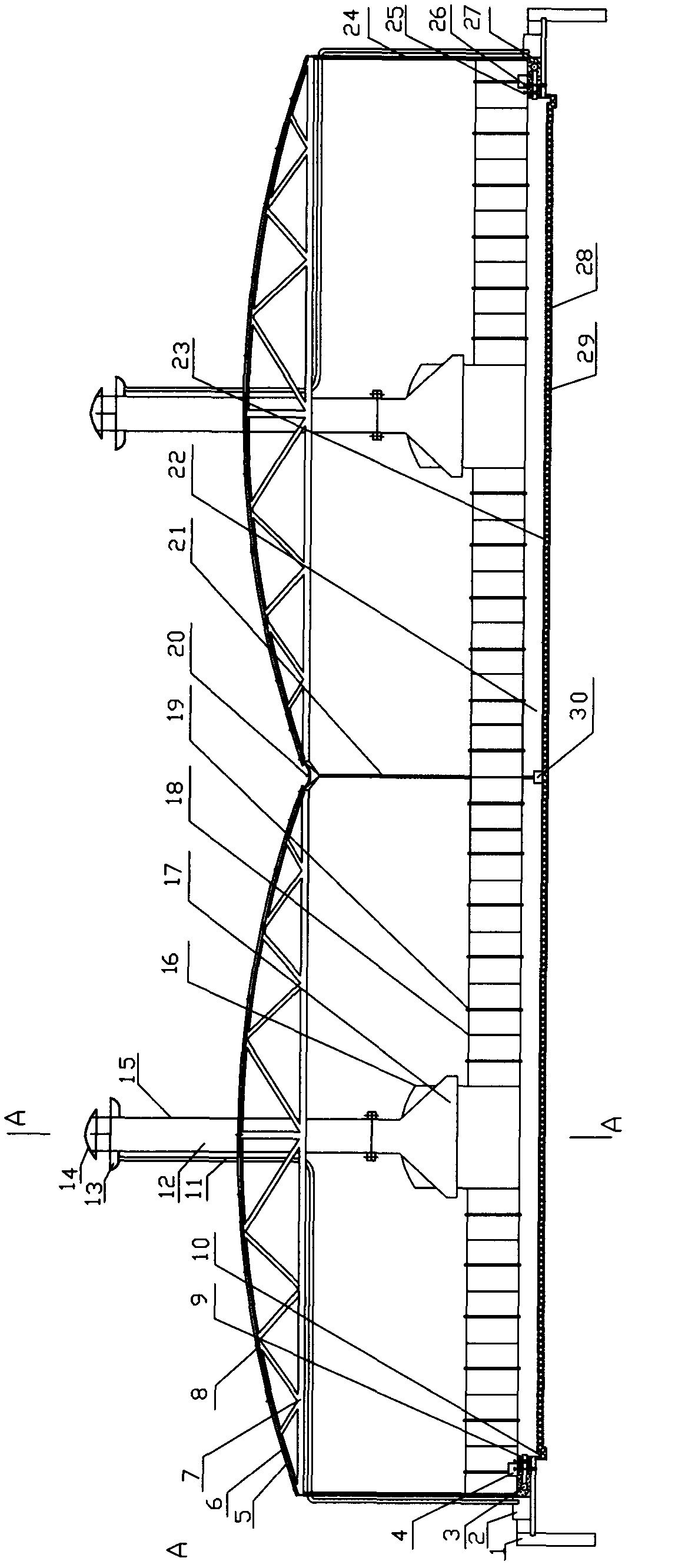

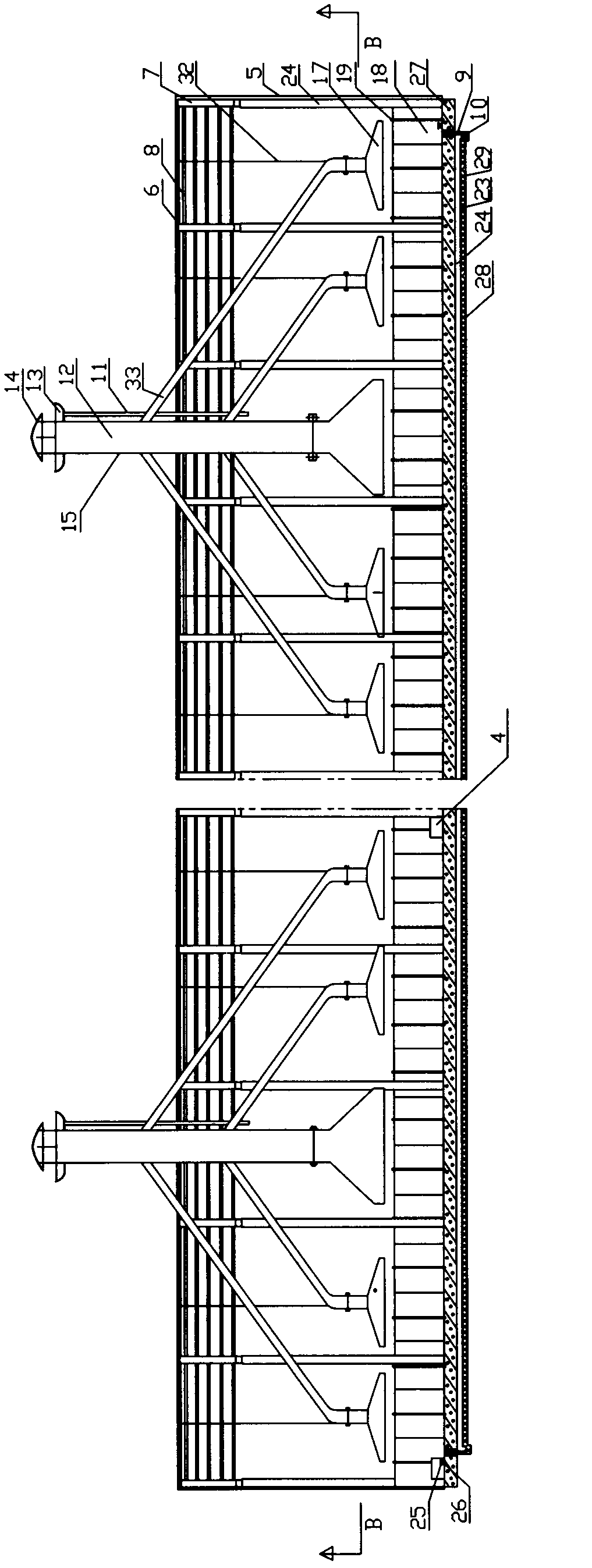

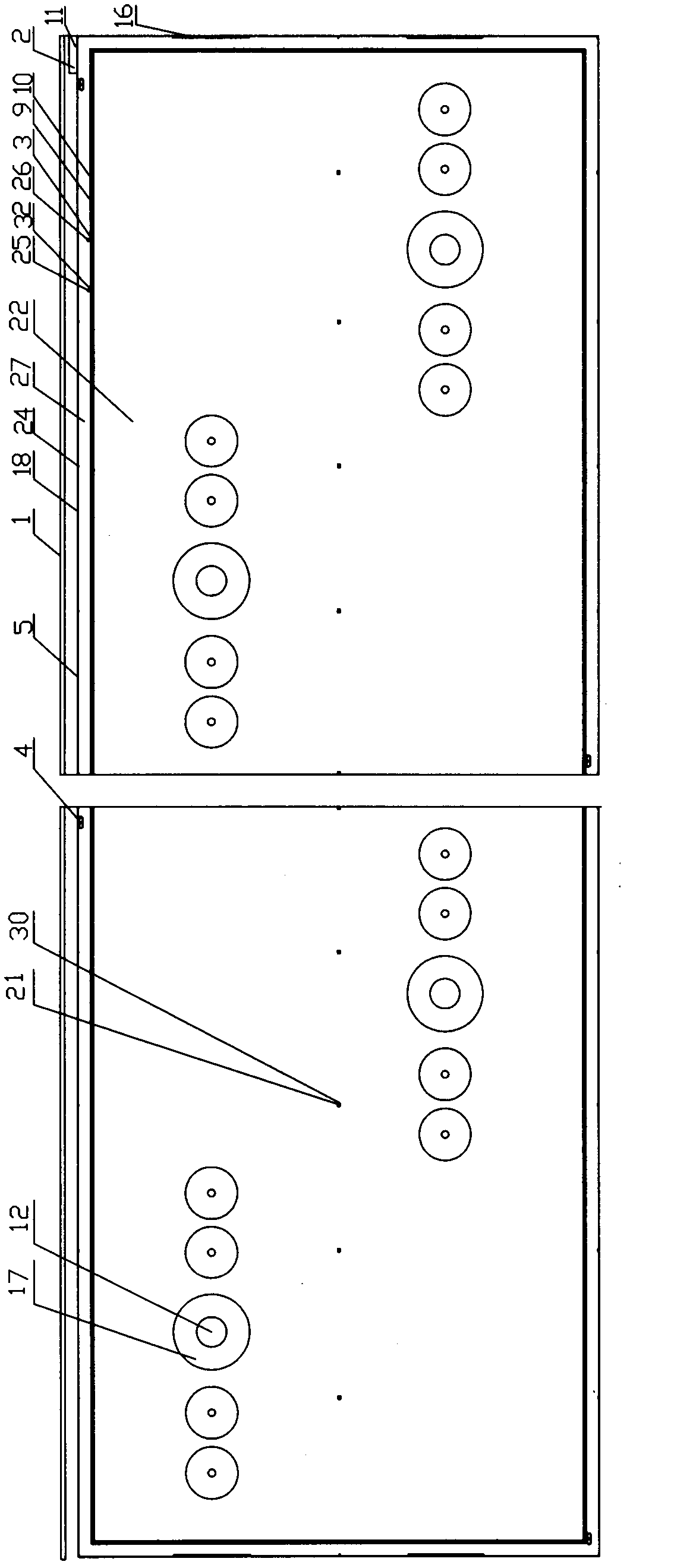

[0023] A brine crystallization salt production device, comprising a crystallization tank 22, brine, a brine inlet pipe 3, a brine discharge ditch 1, and a rainproof device. The crystallization tank 22 is placed in a plastic greenhouse, and the shed body and the crystallization tank 22 form a stable structure that can be used all year round. The large-span, high-space, tightly sealed, and full-light solar greenhouse for salt production is equipped with thermal insulation, ventilation, moisture drainage and water collection devices 15 that are beneficial to salt production.

[0024] The upper part of the greenhouse is an arched structure, and the steel beam 7 is supported by columns 24 and 21. The column 24 is located on the concrete foundation 27 around the crystallization pool 9, and the column 21 is located on the concrete foundation 30 at the bottom of the crystallization pool 22. Plastic film 5 is used. The outsourcing is sealed, with ground windows 18 on four sides, doors 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com