Novel method for direct extraction recovery of ammonia nitrogen from electrolyzed manganese slag

A technology for electrolyzing manganese slag and recovering ammonia, which is applied in the preparation/separation of ammonia, the removal of ammonium sulfate, and solid waste, and can solve the problems of high price of treatment agents, high energy consumption, and harsh reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

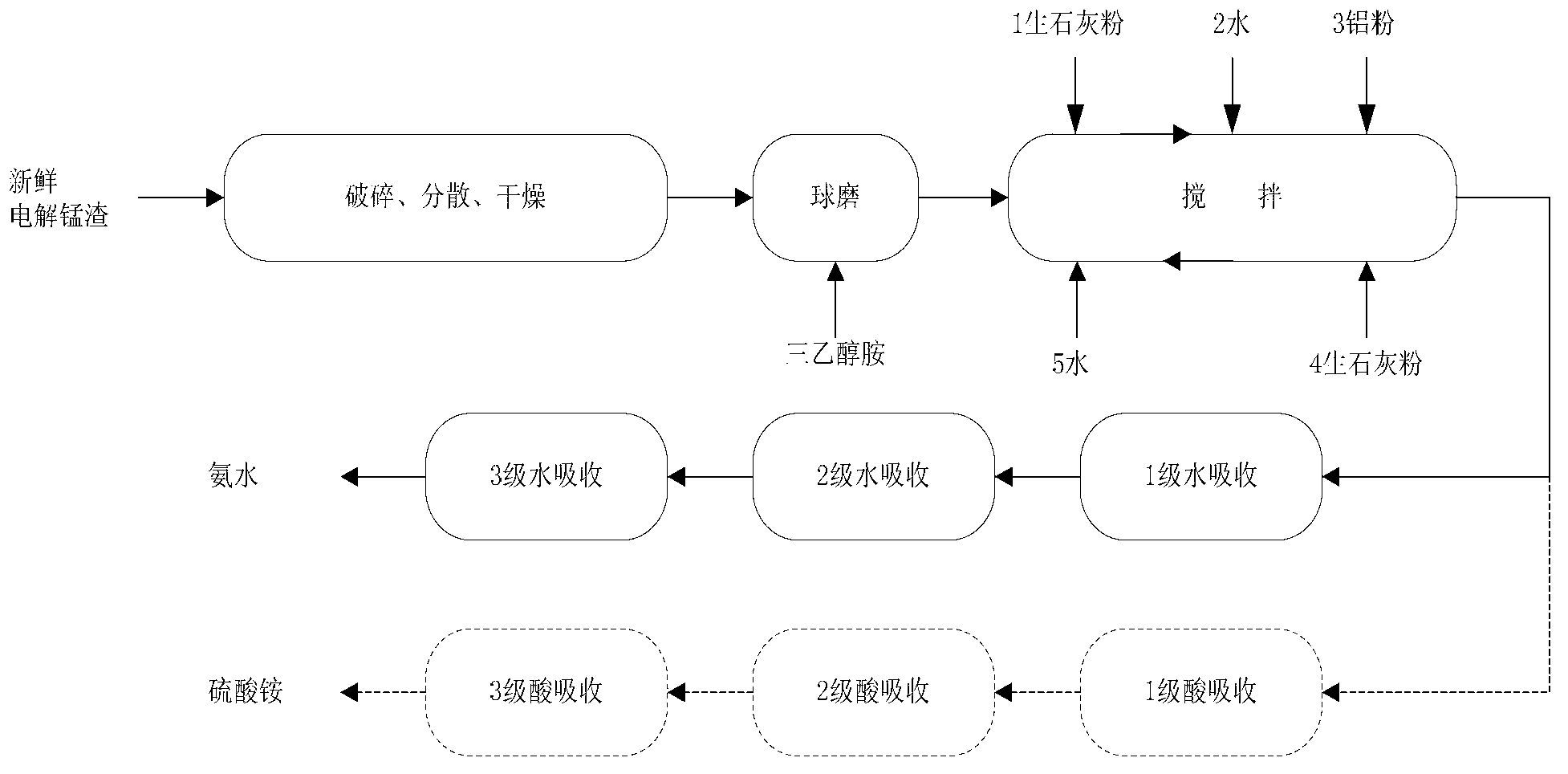

[0024] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it according to the text of the description:

[0025] Step 1: The electrolytic manganese slag just discharged is crushed, dispersed, and dried to obtain material I.

[0026] Step 2: Ball mill the obtained material I, add triethanolamine after running for 2-3 minutes, and continue to run for 3-5 minutes to obtain material II.

[0027] Step 3: Add material II to the mixer, add 5-10% quicklime powder of material II mass, and mix evenly; the quicklime powder used has the following requirements: the fineness of the quicklime powder is required to pass the 120-mesh sieve and the sieve margin is not high Less than 5%, the effective calcium oxide content is not less than 85%.

[0028] Step 4. During the operation of the mixer, add clean water slowly in multiple times, and stop adding water after controlling the mass ratio of the add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com