Multi-orifice zeolite material as well as preparation method and application thereof

A zeolite material and a technology for pore zeolite are applied in the field of preparing multi-level pore zeolite materials and achieve the effects of simple and easy preparation process, simplified synthesis process and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

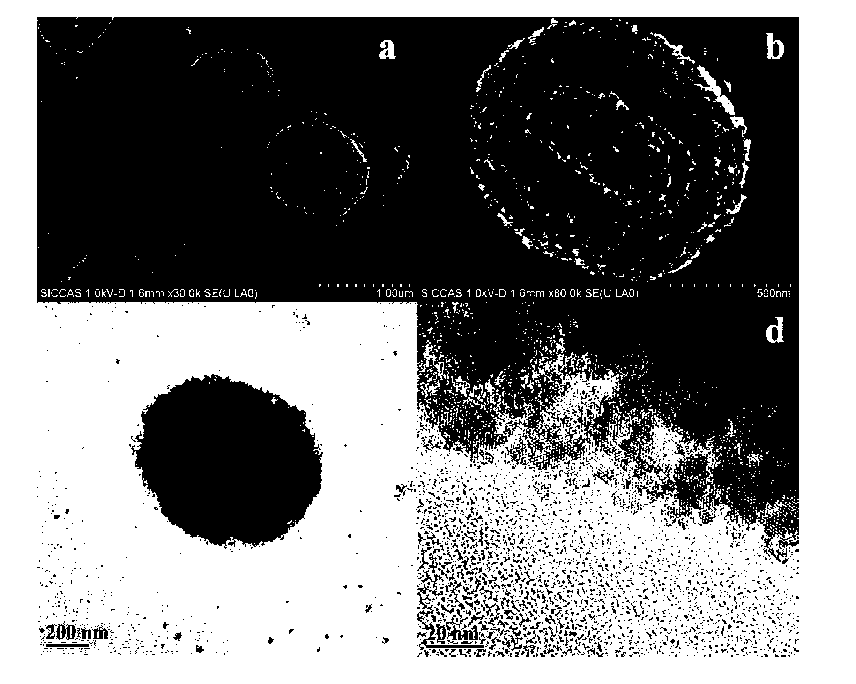

Embodiment 1

[0042] a) Preparation of reaction precursor: at 40°C, add 0.2g of aluminum isopropoxide and 10.4g of ethyl silicate to 18g of water, stir at room temperature for 2h, then dropwise add 4.1g of 25wt% tetrapropylammonium hydroxide aqueous solution;

[0043] b) After 4 hours, add 0.69 g of sucrose to the mixture obtained in a), continue to stir overnight until the reaction mixture becomes solidified, age for 7 hours, and dry in a constant temperature and humidity box at 50°C for 15 hours;

[0044] c) inject 0.12g of water into the bottom of the 100ml polytetrafluoroethylene liner containing the small metal bracket, take 1g of dry glue in b) and place it on the support of the polytetrafluoroethylene liner in the crucible, put it in a stainless steel kettle, At 150°C, steam assisted crystallization treatment for 10h. ;

[0045] d) The crystallized powder above is washed three times with deionized water and absolute ethanol, dried at 100°C under normal pressure for 10 hours, and fi...

Embodiment 2

[0052] The only difference between this example and Example 1 is that the water content used in the steam-assisted crystallization process is 0.08 g. All the other contents are the same as those described in Example 1.

[0053] The structural parameter data of the prepared hierarchically porous zeolite materials are shown in Table 1.

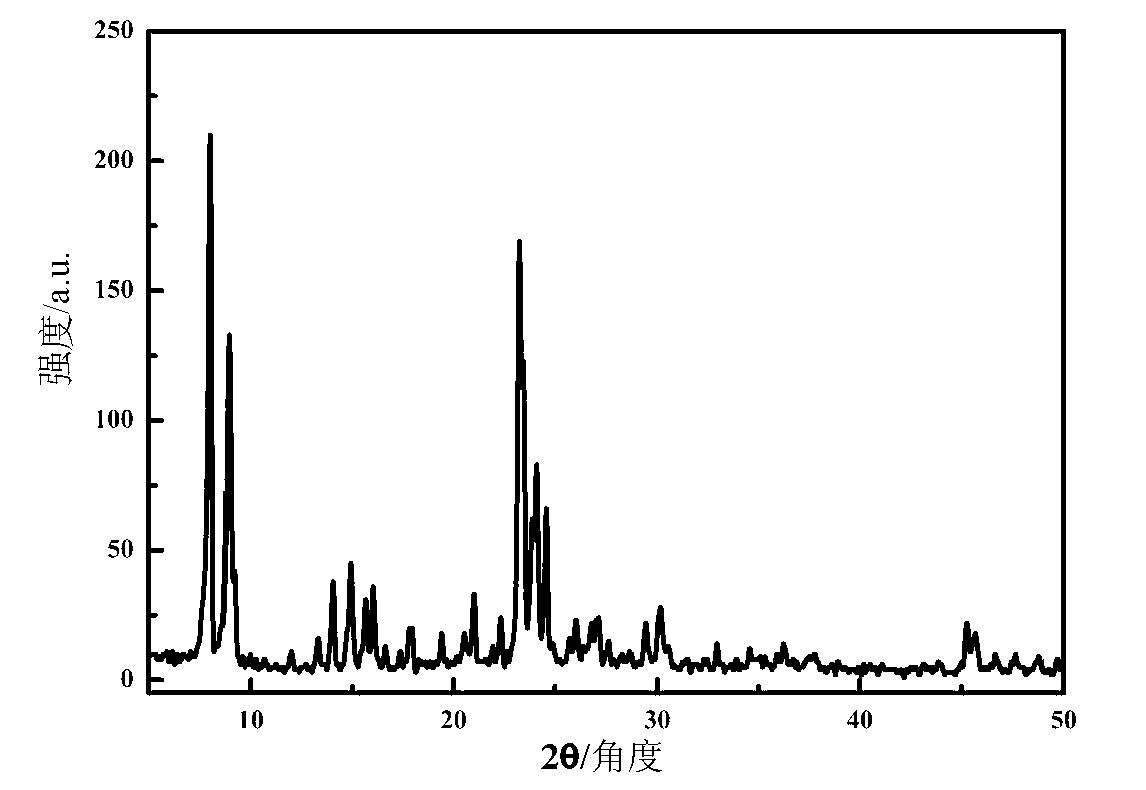

[0054] The XRD spectrum of the prepared hierarchically porous zeolite material is as follows Figure 5 As shown in A.

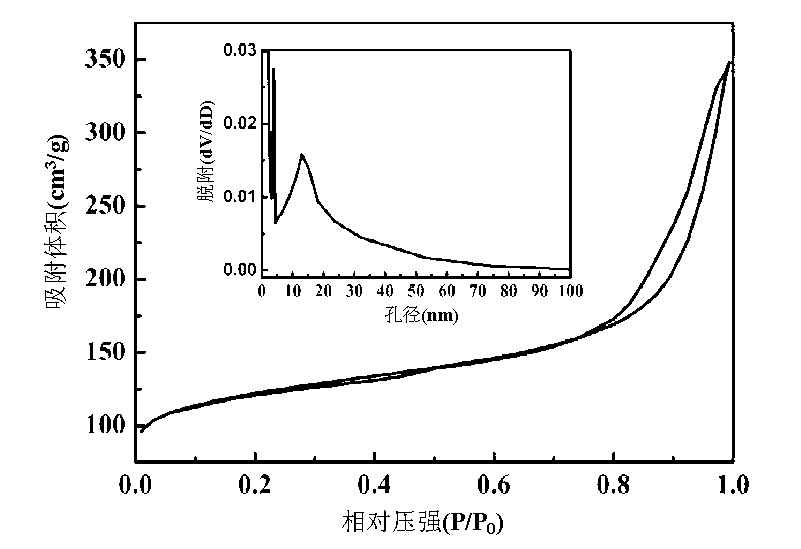

[0055] The nitrogen adsorption-desorption isotherm curve and pore size spectrum of the prepared hierarchically porous zeolite material are as follows: Figure 6a and 6b Shown in curve A.

Embodiment 3

[0057] The only difference between this example and Example 1 is that the water content used in the steam-assisted crystallization process is 0.15 g. All the other contents are the same as those described in Example 1.

[0058] The structural parameter data of the prepared hierarchically porous zeolite materials are shown in Table 1.

[0059] The XRD spectrum of the prepared hierarchically porous zeolite material is as follows Figure 5 Shown in B.

[0060] The nitrogen adsorption-desorption isotherm curve and pore size spectrum of the prepared hierarchically porous zeolite material are as follows: Figure 6a and 6b Shown in curve B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com