External surface modification method of microporous molecular sieve

A technology of microporous molecular sieve and molecular sieve, which is applied in the field of surface modification of microporous molecular sieve, can solve the problem of high cost, achieve the effects of controlling acidity, increasing the ratio of silicon to aluminum, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

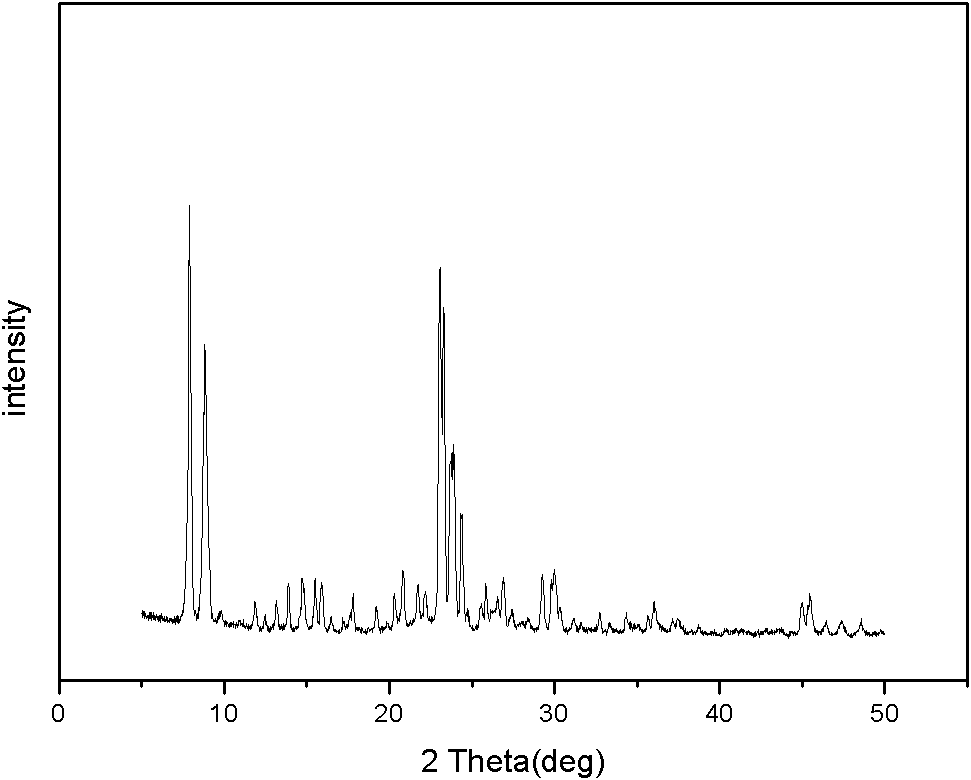

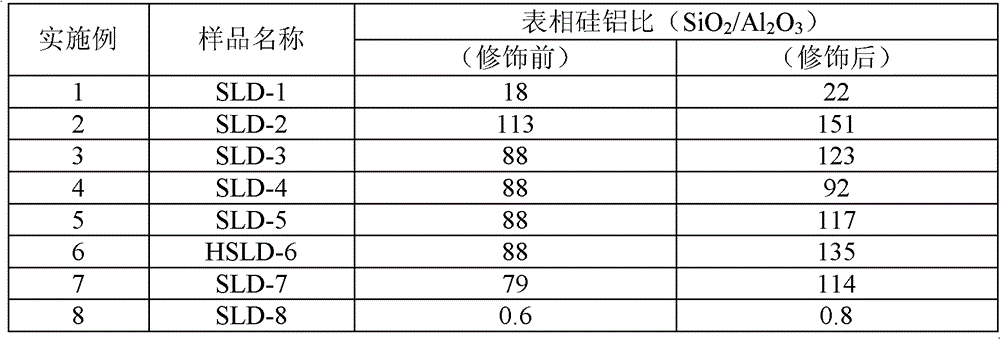

[0033] At 30°C, 30g of commercially available alkaline silica sol (Beijing Xingdaxin Special Materials Co., Ltd., SiO 2 The content is 30wt%) and 90g deionized water in the beaker and mix uniformly, then add the ZSM-5 molecular sieve of 15g Na type under stirring (surface silicon aluminum ratio is 18, purchased from Beijing Bowen Kefeng Technology Development Co., Ltd. ), continue to stir for 4h, stop stirring, stand still at room temperature for 24h, filter, dry at 120°C for 12h, and roast at 540°C for 4h to obtain ZSM-5 molecular sieve with external surface modification, marked as SLD-1. X-ray diffraction (XRD, see figure 1 ) Determination, its phase belongs to ZSM-5 molecular sieve.

Embodiment 2

[0035] At 20°C, 20g of commercially available alkaline silica sol (Beijing Xingdaxin Special Materials Co., Ltd., SiO 2 The content is 30wt%) and 106g deionized water in a beaker and mix evenly, then add the ZSM-5 molecular sieve of 20g Na type under stirring (surface silicon aluminum ratio is 113, purchased from Beijing Bowen Kefeng Technology Development Co., Ltd. ), continue to stir for 4h, stop stirring, stand still at 20°C for 24h, filter, dry at 120°C for 12h, and roast at 540°C for 2h to obtain ZSM-5 molecular sieve with external surface modification, marked as SLD-2. As determined by X-ray diffraction (XRD), its phase belongs to ZSM-5 molecular sieve.

Embodiment 3

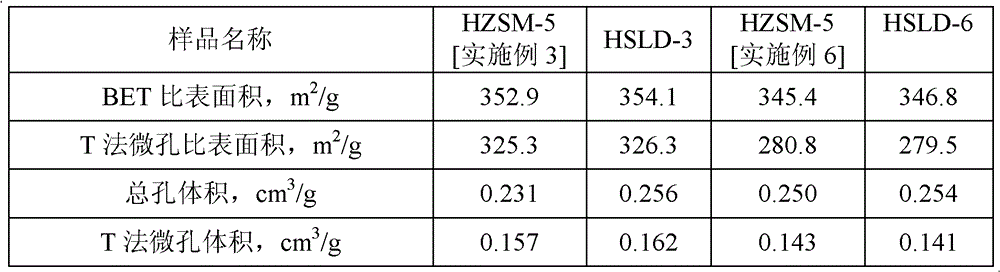

[0037] At 35°C, 7.5g of commercially available alkaline silica sol (Beijing Xingdaxin Special Materials Co., Ltd., SiO 2 content is 30wt%) and 84.75g deionized water are mixed evenly, then add the ZSM-5 molecular sieve of 15g Na type (surface silicon aluminum ratio is 88, purchased from Beijing Bowen Kefeng Technology Development Co., Ltd.), stir 4h, stop Stir, stand still at 35°C for 24h, filter, dry at 120°C for 12h, and calcinate at 500°C for 4h to obtain ZSM-5 molecular sieve with modified outer surface, marked as SLD-3. As determined by X-ray diffraction (XRD), its phase belongs to ZSM-5 molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com