Plant straw harvesting and smashing machine

A plant straw and pulverizer technology, which is applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of complex structure, high operation cost, labor shortage, etc., and achieve the effect of simple operation, flexible and convenient operation, and compact body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

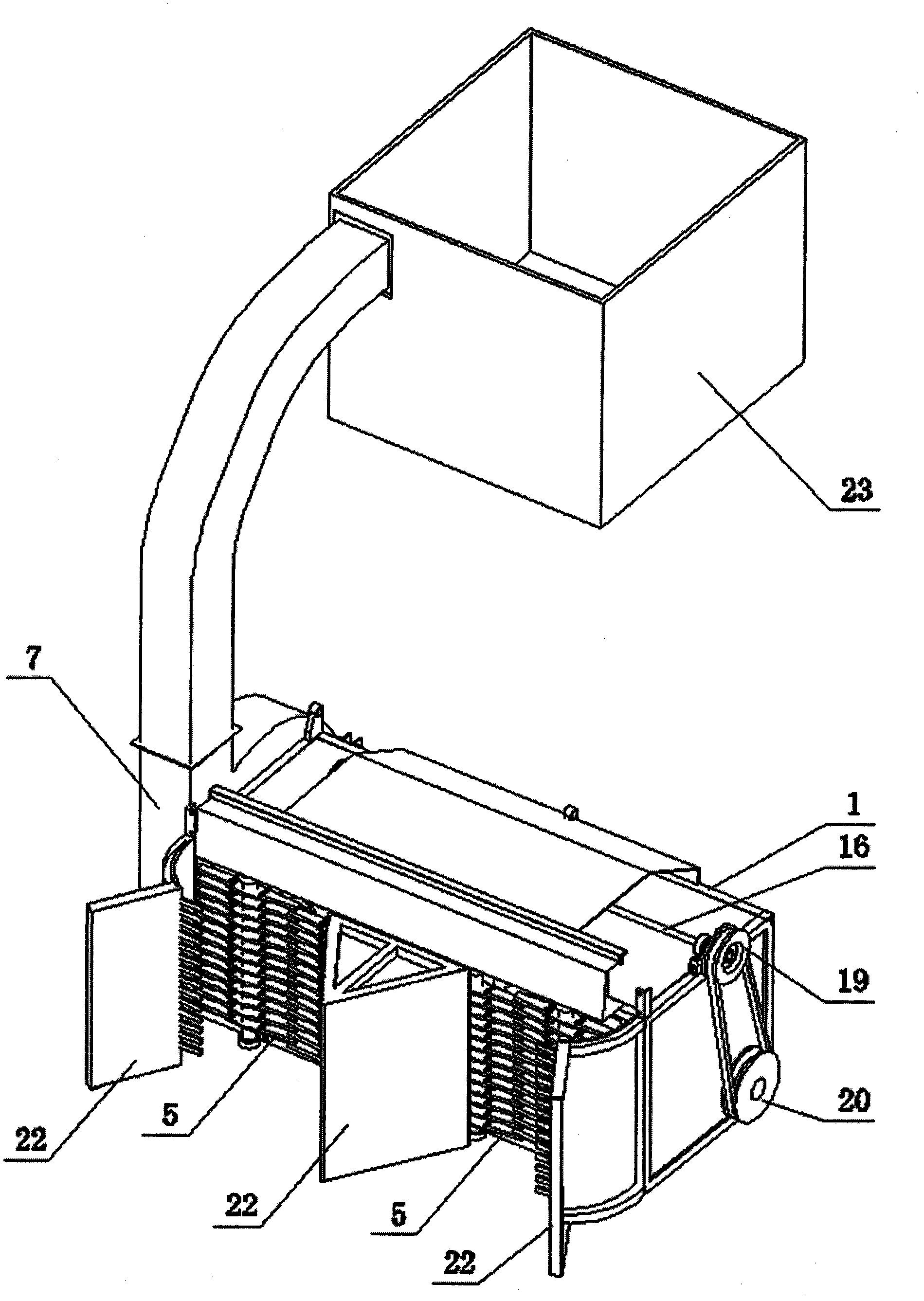

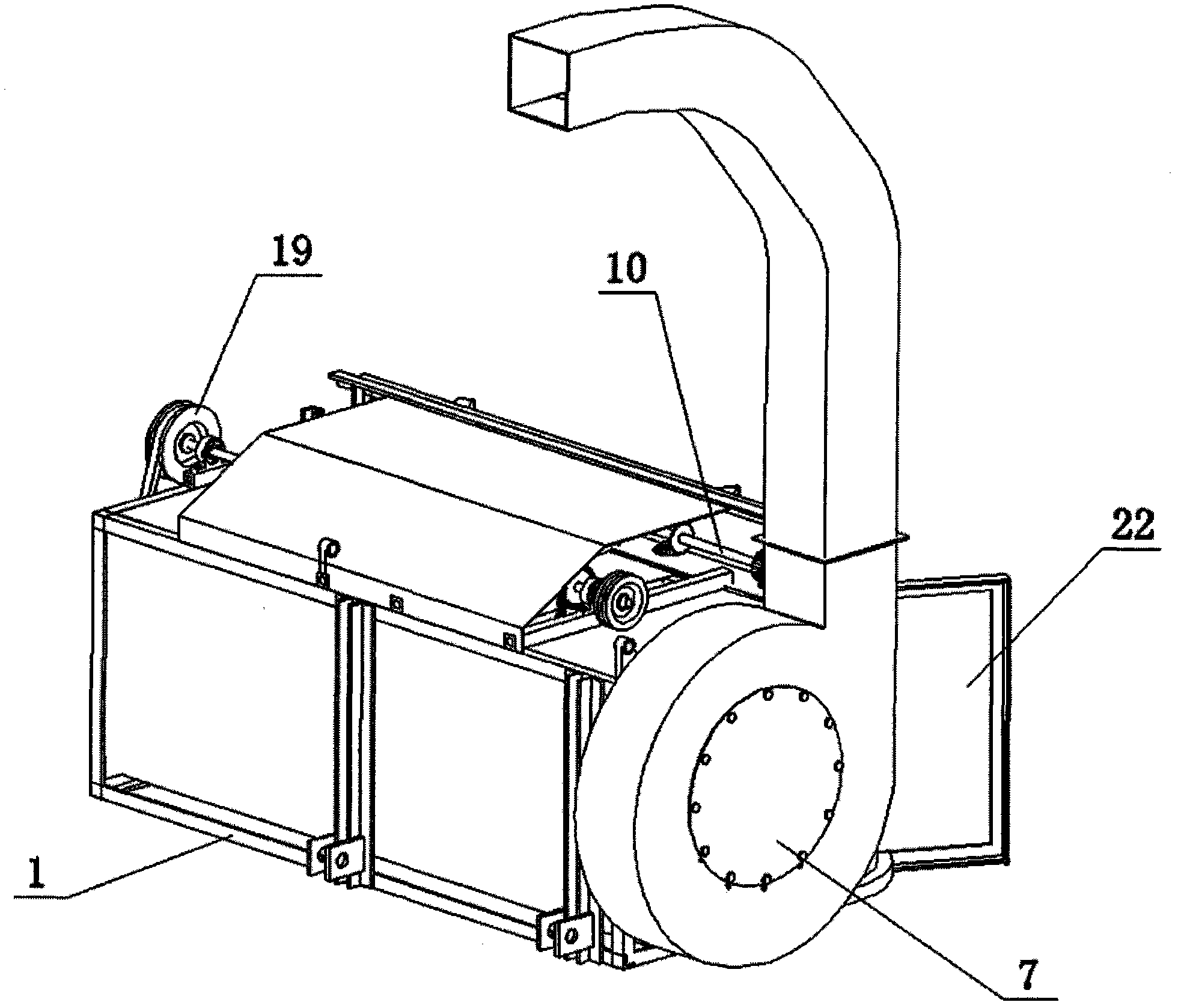

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a plant stalk harvesting grinder includes a body frame 1 and a power transmission system, and a receiving box with an open front side is formed by the body frame 1 and an iron plate; two groups of Cutting and crushing assembly, each group of cutting and crushing assembly includes vertically installed left vertical shaft 2, right vertical shaft 3 and fixed knife rest 4, and 26 movable cutting knives 5 are installed symmetrically at equal intervals on the left vertical shaft 2 and right vertical shaft 3 respectively, and the dynamic The installation mode of cutting knife 5 is left and right symmetrical installation, 13 moving cutting knives 5 on the left side 13 moving cutting knives 5, on fixed knife rest 4 and left vertical shaft 2 and right vertical shaft 3, moving cutting knife 5 is correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com