Hand-push type electric rust knocking and removing machine

A hand-push, rust-removing machine technology, used in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of high labor intensity and low efficiency, and achieve reduced labor intensity and high efficiency. , the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

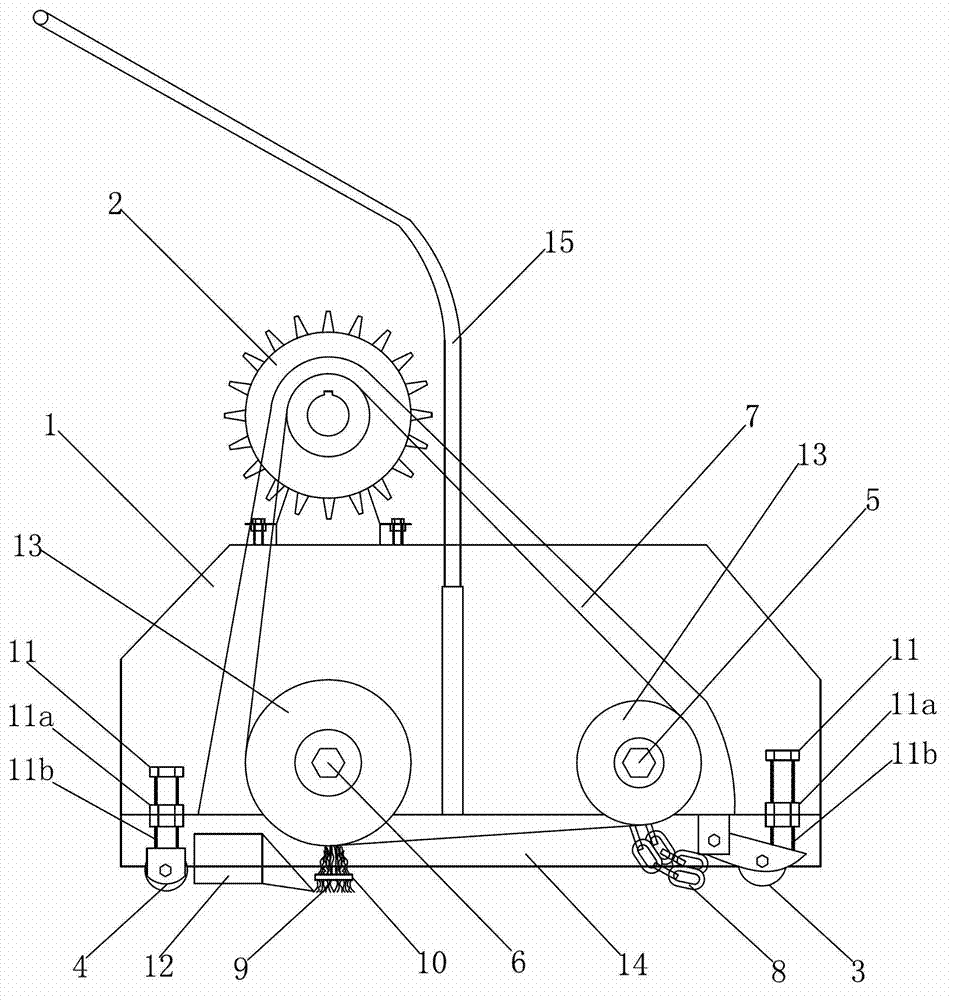

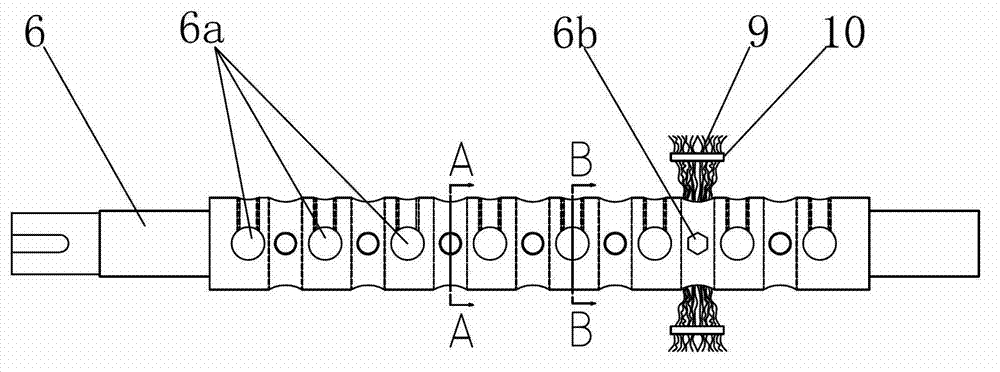

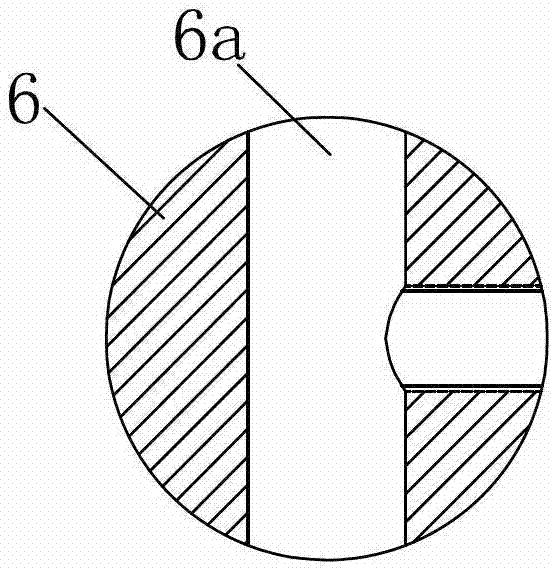

[0029] Such as figure 1 Shown: the present embodiment provides a kind of hand-push electric derusting derusting machine, comprises frame 1, is provided with motor 2 on frame 1, and frame 1 bottom surface is provided with front wheel 3 and trailing wheel 4, and described machine A front shaft 5 and a rear shaft 6 are arranged at the bottom of the frame 1, and the front shaft 5 and the rear shaft 6 are connected to the output end of the motor 3 through a transmission device 7. The front shaft 5 and the rear shaft 6 are respectively provided with Knock rust device 8 and derust device 9. By respectively having the front axle 5 and the rear axle 6 of the derusting device 8 and the derusting device 9, the mechanization of derusting and derusting work is realized, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com