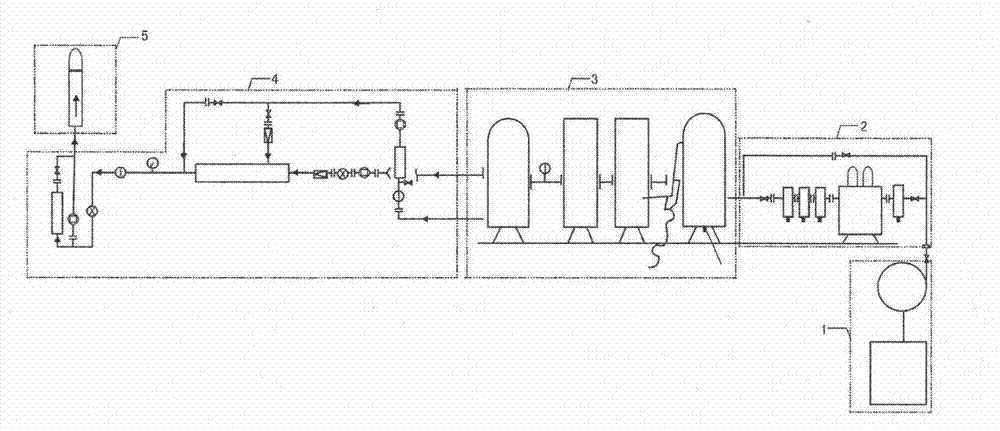

Adjustable oxygenation energy-saving combustion-supporting system

A combustion-supporting system and adjustable technology, applied in the transportation of non-flammable liquid/gas, combustion method, oxygen preparation, etc., can solve the problems of unclean filter element, low pressure, limited range, etc., and achieve increased product quality and environmental protection product quality , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Application on 20T Coal Steam Chain Boiler

[0065] A 20T chain steam boiler, the steam working pressure requirement is 2.55MPA, the thermal efficiency is 80%, the fuel is coal with a calorific value of 5200-5300 kcal, and the daily coal consumption of the boiler is 76- 80 tons, the furnace temperature is 923°C, the blast frequency is 44HZ, the induced air frequency is 48.8HZ, the grate width is 3M, and the grate speed is 538r / min. The steam flow rate is 20T / H, the carbon content of the fly ash is 2.543, the fire in the front arch combustion area of the grate is not good, the fire bed moves to the cinder area behind the fire bed, and there is black smoke from the chimney.

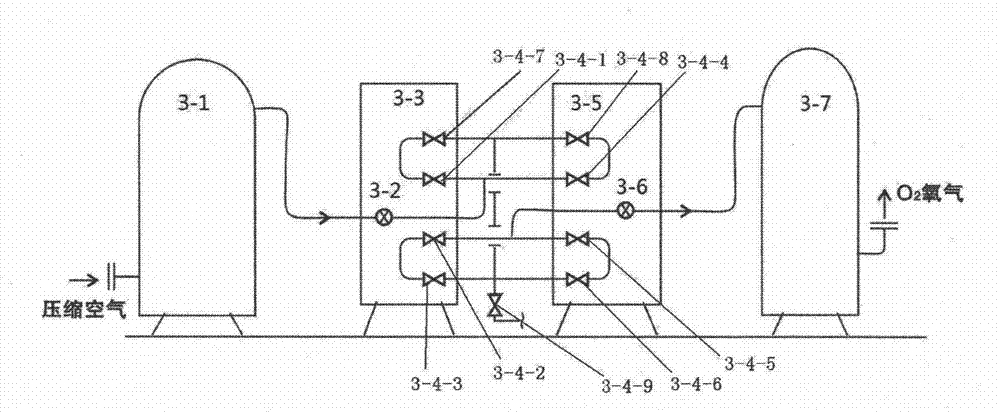

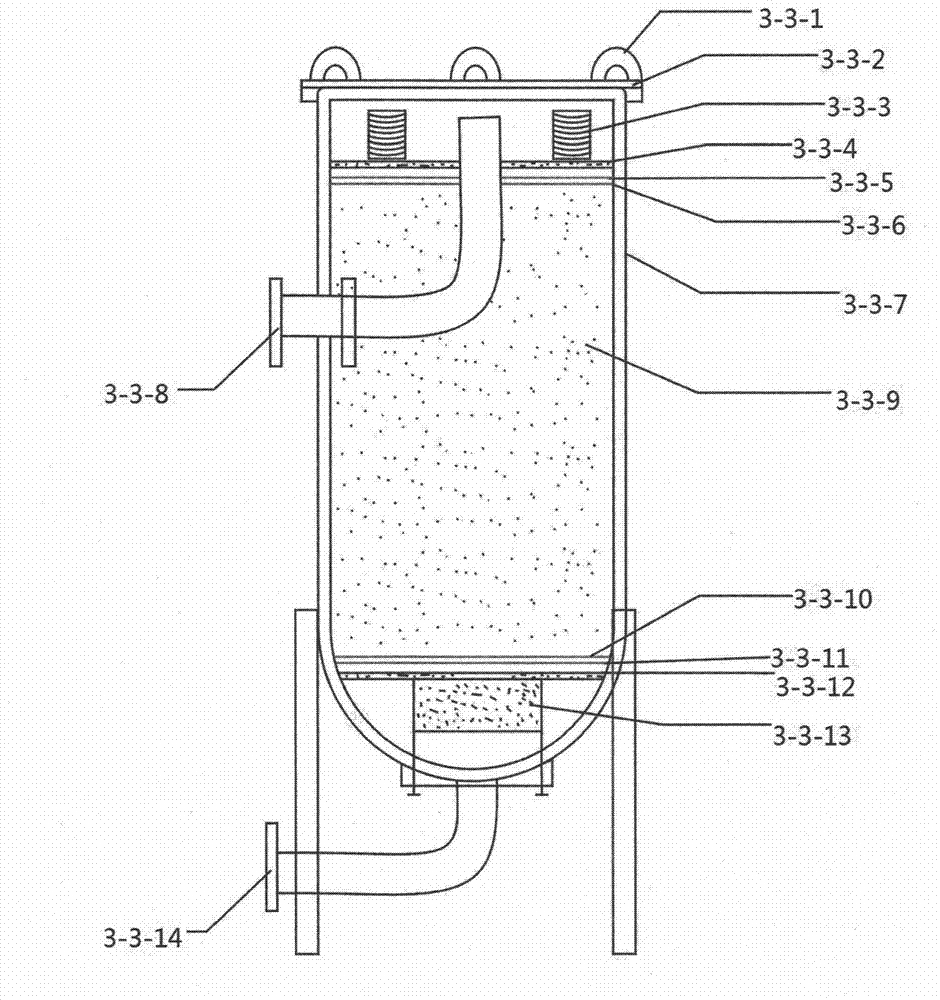

[0066]According to the above parameters, an adjustable oxygen-increasing, energy-saving and combustion-supporting system is adopted, and an air compressor with a pressure of 0.7MPA and a flow rate of 10M3 / MIN is selected. After the dryer, the compressed air enters the combined low dew p...

Embodiment 2

[0068] Embodiment 2: the application on the horseshoe flame kiln that fuel is natural gas

[0069] 18m 2 Two horseshoe flame furnaces form a group, the fuel is natural gas, and when air is used for combustion: the gas consumption of a single kiln is about 230-240m3 3 / h, the annual operating time is 8400 hours, the melting temperature is 1535°C, the temperature of the Dalong is 1535°C, the air preheating temperature is 1160°C, the exhaust gas temperature is 350°C, the excess air coefficient is 1.2, and the combustion air volume is 8900m3 / h , wind pressure 1226pa, 5.5KW, frequency conversion 24.5HZ, a single furnace is equipped with 4 spray guns, two as a group, and the design value of the natural gas flow rate of each spray gun is 150m 3 / h, switch once in about 20 minutes, the high-pressure air adopts 0.04MPA, the secondary air opening is 25HZ, the distance between the two furnaces is 10 meters, and a cumulative flow meter is installed for natural gas consumption, and the un...

Embodiment 3

[0072] Embodiment 3: Application on the rotary kiln where the fuel is heavy oil

[0073] The basic usage conditions of a rotary kiln for firing refractory materials are: the diameter of the rotary kiln is 2.5 meters, the length is 90 meters, the firing temperature of the kiln head is 1800 degrees, the pressure of the kiln head is 10-50pa, when the air is used for combustion, the oil is atomized Wind is compressed air: pressure 0.4Mpa, pipe diameter 10MM, high-pressure air is Roots blower: pressure 0.2Mpa, pipe diameter 60MM×2, flow rate 20m3 / min, blast is 15KW, air volume is about 6000M3 / H, for intermittent use , the oil pressure of heavy fuel oil is 0.4Mpa, the pipe diameter is 4.5MM, the current flame length is 12 meters, the daily output is 180-200 tons / day, the fuel consumption per ton is about 120KG / ton, the flue gas temperature is 250 degrees, and the secondary air temperature 600-750 degrees, one spray gun at the kiln head, and the diffusion angle is 120 degrees. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com