Ladle furnace refining fluoride-free pre-melted slags, preparation method and using method

A ladle furnace refining and pre-melting slag technology, which is applied in the field of ladle metallurgy for refining outside the steelmaking furnace, can solve the problems of low dephosphorization efficiency, difficulty in rephosphorization control, slag melting performance, inclusion absorption performance, and low cost. Achieve the effect of improving stability and metallurgical effect, strong desulfurization, dephosphorization and rephosphorization control ability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

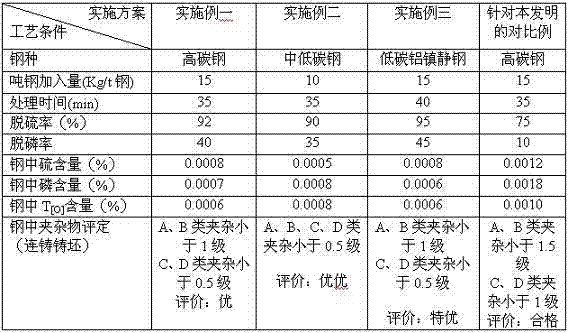

[0032] The present invention will be further elaborated below in conjunction with the examples; the examples are only used to illustrate the present invention, but not to limit the present invention in any way.

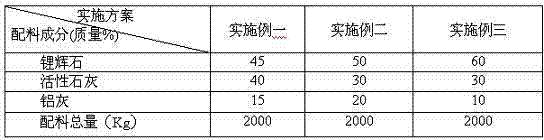

[0033] The composition characteristic of the preparation process of embodiment and the raw material that adopts is as follows:

[0034] (1) Preparation of premelted refining slag

[0035] The raw materials that embodiment adopts are as follows, and when referring to percentage below, all are percentage by weight:

[0036] The composition of spodumene is calculated by mass percentage, Li 2 O 5.0%, Al 2 o 3 19.4%, SiO 2 74%, Na 2 O 0.24%, K 2 O 0.28%, Fe 2 o 3 0.11%, MnO 0.04%, TiO 2 0.02%, P 2 o 5 0.09%, S 0.02, and the balance is trace impurities of unknown ingredients.

[0037] The composition of lime is calculated by mass percentage, CaO 90.0%, MgO 4.0%, SiO 2 1.5%, the rest are impurities, among which S ≤0.035%, P ≤0.015%.

[0038] The aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com