Technology of sodium-based serial composite modified briquette for gasification

A technology of briquette and technology, which is applied in the field of pulverized coal forming, can solve the problems of poor thermal strength, low thermal strength of briquette, and increased content of coal ash powder in the briquette.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

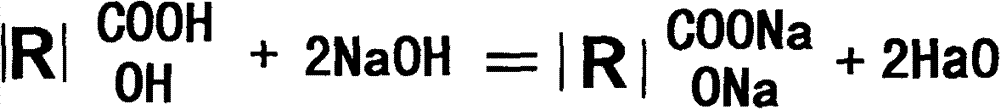

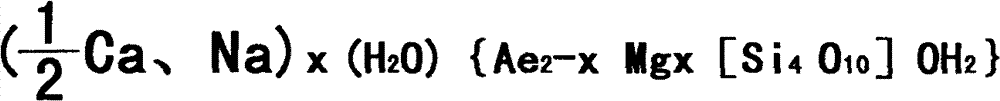

Method used

Image

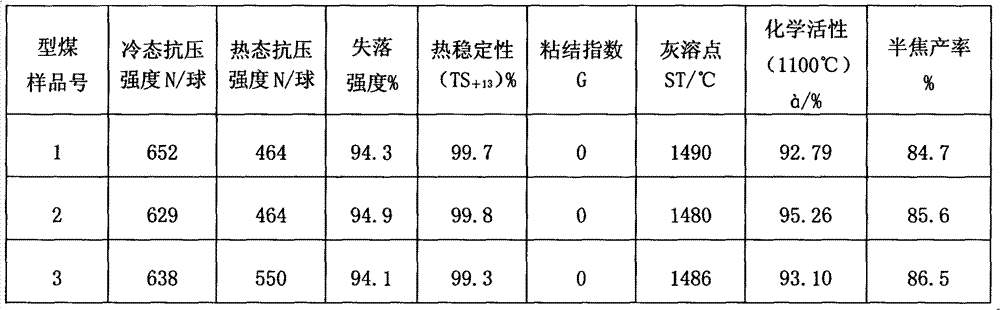

Examples

Embodiment Construction

[0021] The processing technology of sodium-based series composite modified briquettes for gasification is the same as that of cold-pressed binders commonly used in China, the difference is only in the types of binders. The main process and equipment are briefly described as follows: firstly, the raw coal entering the plant is screened, and the coal is crushed to a particle size of 0-3mm with a squirrel-cage crusher. The dosage ratio of the binder is generally controlled at about 10:0.8~1 according to the properties of pulverized coal, and the moisture content of the material is controlled at about 10~12% for stirring and kneading, and then sent to the double-roll molding machine with a belt conveyor, and the molding pressure is 12~ 30MPa; In order to ensure that the binder becomes a strong skeleton inside the briquette, the formed briquette is dried and consolidated by using a vertical drying furnace to dry and consolidate the briquette The water content in the coal is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com