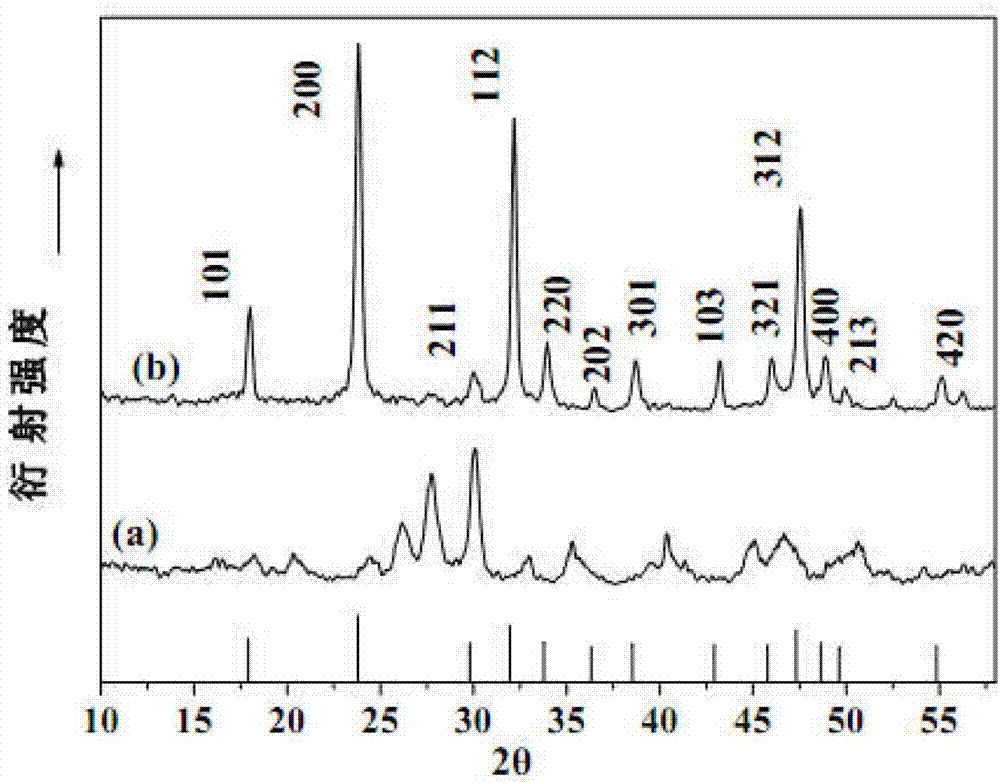

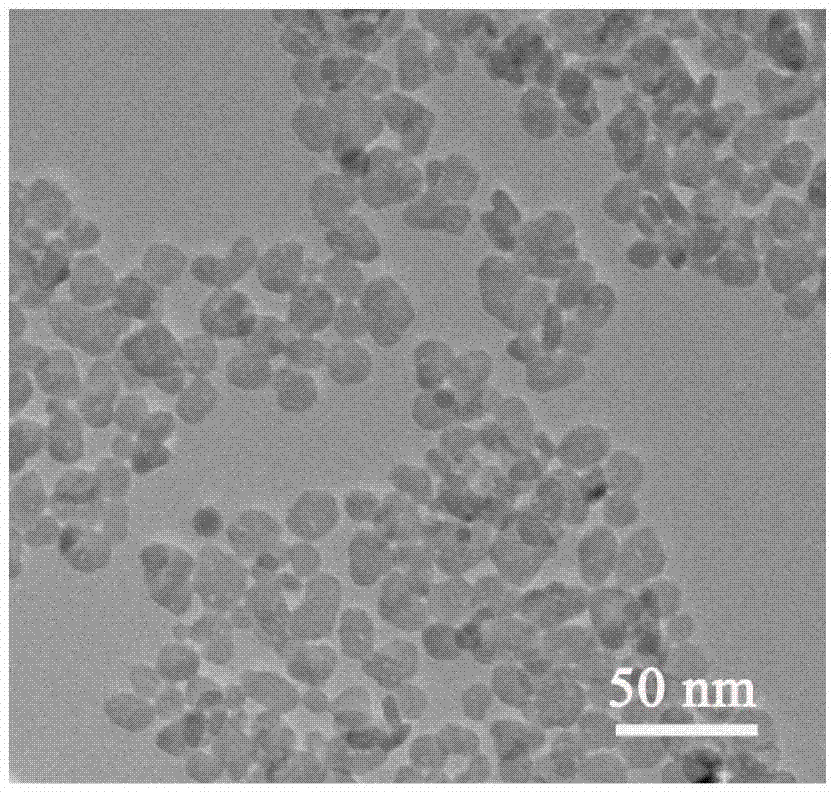

Preparation method of water-soluble rare earth luminous nanocrystallines with functionalized surfaces

A technology of surface functionalization and rare earth luminescence, which is applied in chemical instruments and methods, luminescent materials, dyeing polymer organic compound treatment, etc., can solve the problems of difficult degradation and toxicity, and achieve low cost, uniform size and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Weigh 0.045mol lanthanum nitrate hexahydrate, 0.0025mol cerium nitrate hexahydrate and 0.0025mol terbium nitrate hexahydrate respectively with an electronic balance, and make 100ml uniform solution with deionized water, and the total rare earth concentration is 0.5mol / L;

[0024] 2. Add 0.1g of polysuccinimide with a molecular weight of 6000 to a 50ml reaction kettle, add 15ml of water, and then dropwise add 1ml of 1.0mol / L sodium hydroxide aqueous solution, and after fully stirring, a red transparent polyaspartame is obtained acid solution;

[0025] 3. Put 0.126g of sodium fluoride in 15ml of water and stir thoroughly to obtain a clear and transparent solution;

[0026] 4. Add the clear and transparent solution obtained in step 3 to the solution obtained in step 2, and stir for 10 minutes; then add 2ml of the rare earth nitrate mixed solution prepared in step 1, and continue stirring for 15 minutes to fully chelate it to obtain a milky white glue Liquid;

[0027] ...

Embodiment 2

[0030] 1. Weigh 0.0490mol lanthanum nitrate hexahydrate and 0.0010mol europium nitrate hexahydrate respectively with an electronic balance, and make 100ml uniform solution with deionized water, the total rare earth concentration is 0.5mol / L, and the molar ratio between rare earth elements The ratio is La:Eu=98:2;

[0031] 2. Add 0.1g of polysuccinimide with a molecular weight of 6000 to a 50ml reaction kettle, add 15ml of water, and then dropwise add 1ml of 1.0mol / L sodium hydroxide aqueous solution, and after fully stirring, a red transparent solution is obtained;

[0032] 3. Put 0.12g of ammonium metavanadate in 15ml of water, add 2mmol of sodium hydroxide, and stir thoroughly to obtain a clear and transparent solution;

[0033] 4. Add the clear and transparent solution obtained in step 3 to the solution obtained in step 2, and stir for 10 minutes; then add 2ml of the rare earth nitrate mixed solution prepared in step 1, and continue stirring for 15 minutes to fully chelate ...

Embodiment 3

[0037] 1. Weigh 0.0490mol lanthanum nitrate hexahydrate and 0.0010mol europium nitrate hexahydrate respectively with an electronic balance, and make 100ml uniform solution with deionized water, the total rare earth concentration is 0.5mol / L, and the molar ratio between rare earth elements The ratio is La:Eu=98:2;

[0038] 2. Add 0.1g of polysuccinimide with a molecular weight of 6000 to a 50ml reaction kettle, add 15ml of water, and then dropwise add 1ml of 1.0mol / L sodium hydroxide aqueous solution, and after fully stirring, a red transparent solution is obtained;

[0039] 3. Put 0.12g of ammonium metavanadate in 15ml of water, add 3mmol of sodium hydroxide, and stir thoroughly to obtain a clear and transparent solution;

[0040]4. Add the clear and transparent solution obtained in step 3 to the solution obtained in step 2, and stir for 10 minutes; then add 2ml of the rare earth nitrate mixed solution prepared in step 1, and continue stirring for 15 minutes to fully chelate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com