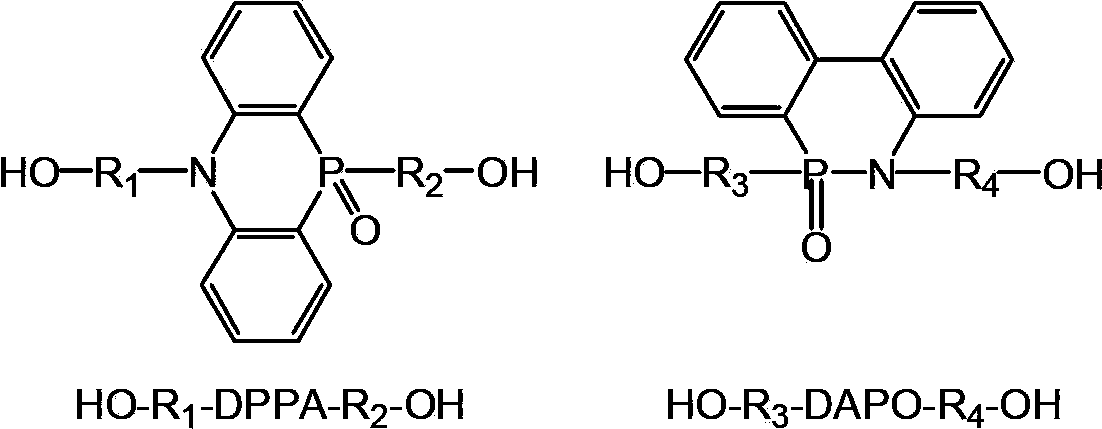

Phosphorus and nitrogen heterocycle-containing organic halogen-free flame retardant and its preparation method

A nitrogen heterocycle and flame retardant technology is applied in the field of organic halogen-free flame retardants and their preparation, which can solve the problems of material heat resistance and other performance degradation, and achieve mild preparation reaction conditions, high yield and controllable reaction process. adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

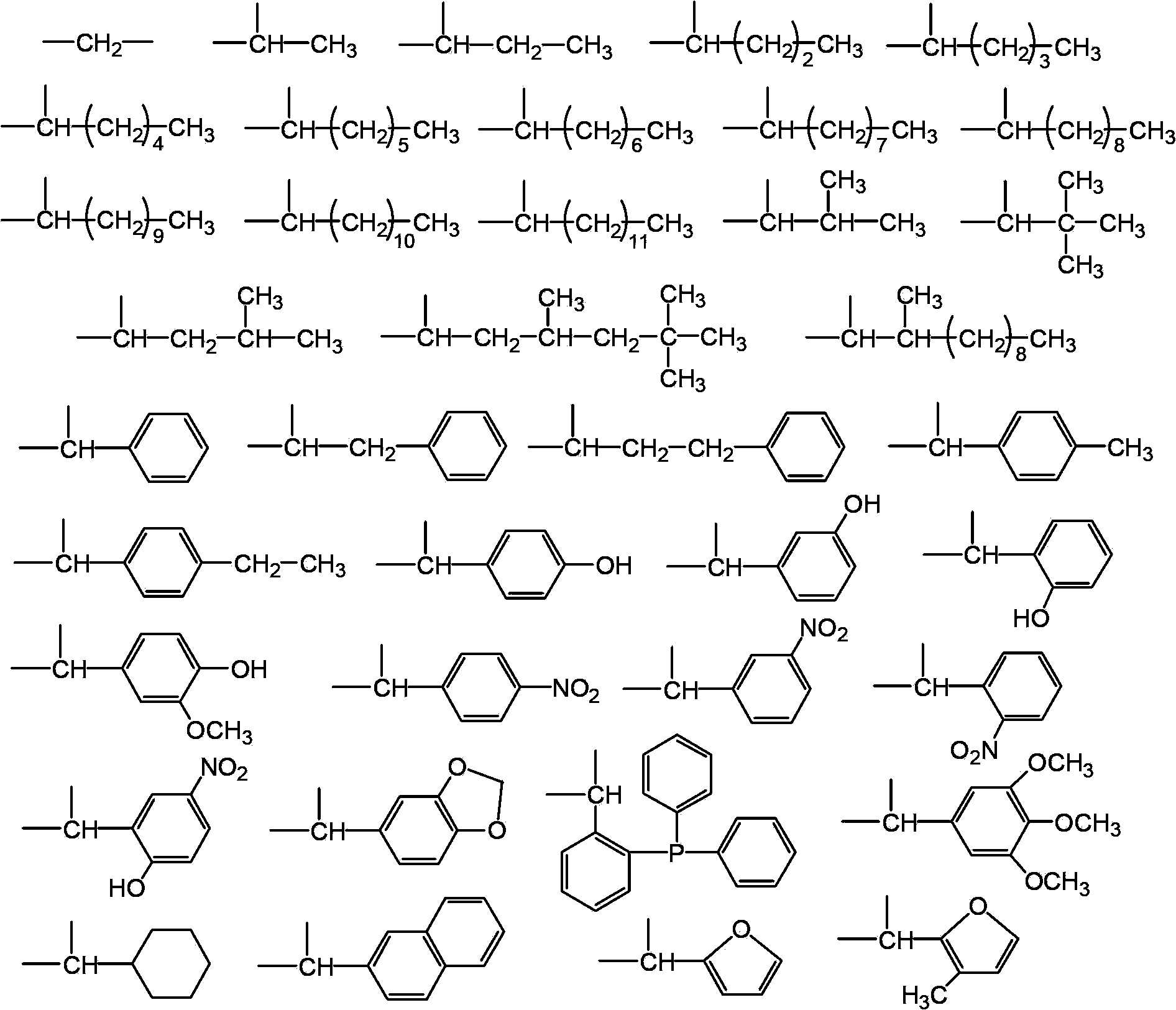

Embodiment 1

[0029] Preparation steps of organic halogen-free flame retardant: Add 21.5g DPPA and 100ml xylene into a 500ml flask equipped with a condenser, mechanical stirring, constant pressure dropping funnel and nitrogen protection, raise the temperature to 90°C, and wait until DPPA is completely dissolved in 1 Add 16.5ml of 37% formaldehyde solution and 10ml of xylene solution containing 0.15g of triethanolamine dropwise within 1 hour, continue to react for 0.5 hour, then filter the reaction mixture, wash with ethanol, and vacuum dry at 60°C for 12 hours to finally obtain phosphorus-containing nitrogen Heterocyclic organic halogen-free flame retardant HO-CH 2 -DPPA-CH 2 -OH 36.1 g, yield 91.8%. Organic Halogen Free Flame Retardant HO-CH 2 -DPPA-CH 2 The mass percentage content of each element in -OH is: C69.14%, H5.76%, O6.58%, P12.76%, N5.76%; the nuclear magnetic spectrum data are: 1 H NMR (DMSO-d6): 7.00-7.88ppm (8H, Ph-H), 4.00-4.30ppm (4H, P-CH 2 -, N-CH 2 -), 5.58-5.64ppm ...

Embodiment 2

[0031] Add 21.5g DAPO and 120ml ethyl acetate / isopropanol (volume ratio 1 / 1) into a 500ml flask equipped with a condenser, mechanical stirring, constant pressure dropping funnel and nitrogen protection, raise the temperature to 75°C, and wait until DAPO is completely dissolved After that, 60ml of acetone solution containing 33g of 2-naphthaldehyde and 10ml of chloroform solution containing 0.2g of hexamethylenetetramine were added dropwise within 2 hours, and the reaction was continued for 1 hour, then the reaction mixture was subjected to rotary evaporation, filtration, ethanol washing, and 60 After vacuum drying at ℃ for 12 hours, 50.6 g of an organic halogen-free flame retardant containing phosphorus and nitrogen heterocycles was finally obtained, with a yield of 92.8%. The effect of flame retardant FRH-2 on the thermal stability of polymer materials and the flame retardant effect are shown in Table 1.

Embodiment 3

[0033]Add 21.5g DPPA and 250ml methanol / toluene (volume ratio 1 / 2) into a 500ml flask equipped with a condenser, mechanical stirring, constant pressure dropping funnel and nitrogen protection, raise the temperature to 65°C, and wait for 0.5 hours after DPPA is completely dissolved Add 50ml of ethanol solution containing 12.2g p-hydroxybenzaldehyde and 11.2g cyclohexyl formaldehyde and 10ml of ethanol solution containing 0.6g benzyldimethylamine dropwise, continue to react for 16 hours, then the reaction mixture is filtered, washed with ethanol, 60 After vacuum drying at ℃ for 12 hours, 40.9 g of an organic halogen-free flame retardant containing phosphorus and nitrogen heterocycles was finally obtained, with a yield of 91.1%. The effect of flame retardant FRH-3 on the thermal stability of polymer materials and the flame retardant effect are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com