Biological organic fertilizer produced from abamectin fermentation waste residue and preparation method thereof

A bio-organic fertilizer and abamectin technology, applied in the field of agricultural biology, can solve the problems of inability to produce bio-organic fertilizers, inability to degrade abamectin fermentation residues, etc., and achieve shortening of decomposing time, speeding up degradation speed, and accelerating decomposing and aging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1. preparation of Abamectin degrading bacterial agent

[0020] 1) The abamectin-degrading bacteria AZ11 slant-preserved test tube seeds were inoculated into LB liquid medium, and shaken at 40-45°C until the logarithmic growth phase;

[0021] 2) Inoculate the cultured bacterial solution into a 10L seed fermenter with 10% inoculation amount, and cultivate it at 40-45°C until the logarithmic growth phase. The cultivation and formula of the seed fermenter are: corn flour 2%; bean cake powder 1 %; Glucose 0.5%; K 2 HPO 4 0.4%; MgSO 4 ·7H 2 O 0.02%; CaCO 3 0.2%; pH 7.2-7.5;

[0022] 3) Inoculate the fermented liquid of the seed fermenter with 10% inoculum into the production fermenter for fermentation production. The medium formula used in the fermentation production is: corn flour 3%; bean cake flour 2%; CaCO 3 0.5%;K 2 HPO 4 0.2%; ZnSO 4 ·5H 2 O 0.05%; MgSO 4 ·7H 2 O 0.05%; pH 7.2;

[0023] The fermentation production process conditions...

Embodiment 2

[0025] Embodiment 2. Abamectin fermentation waste residue bio-organic fertilizer preparation

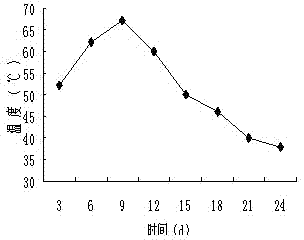

[0026] According to the weight ratio of 50% of abamectin waste residue, 40% of straw, and 10% of chicken manure, the composition of the pile is prepared, and water is added until the water content is 60%, and stirred evenly; refer to the size of the fermentation site, and the length of the pile is 10.0 meters, and the width is 8.0 meters. , with a pile height of 1.5 meters; after the pile temperature rises to 40°C, inoculate the degrading bacteria agent weighing 1% of the total weight of the raw materials (dry weight) on average twice, with an interval of 4 days; use fully automatic fermentation every 3 days Turn the pile once with the mixer, ventilate for 1.5 hours every 12 hours, and ferment for 24 days. When the pile temperature drops below 40°C, the high-temperature fermentation process is over, and the residue of abamectin in the pile is detected; at this time, the fermentation m...

Embodiment 3

[0027] Embodiment 3 The screening of the preparation process condition of bio-organic fertilizer of the present invention, preferred test

[0028] The test method is to change one process condition, fix the other conditions (not necessarily the optimal point), conduct a fermentation test, and evaluate the optimal process parameters by measuring the degradation rate of abamectin waste residue.

[0029] 1) Determination of the inoculum amount of degrading bacteria

[0030]After the stacking temperature naturally rises to 40°C, inoculate the degrading bacteria agent at 0.1%, 0.5%, and 1% inoculum respectively, and set a control without inoculation, turn the stack once every 3 days with a fully automatic fermentation mixer, and detect Avi The remaining amount of mycocin is fermented until the pile temperature is below 40°C.

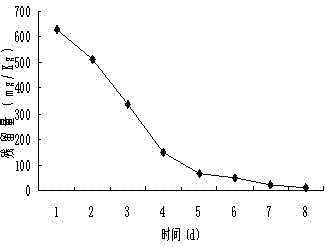

[0031] The results showed that adding the degrading bacteria agent could significantly improve the degradation of abamectin in the pile. At the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com